high quality warman slurry pump bearing assembly supplier

Latest articles

Magnetite mixing

high quality warman slurry pump bearing assembly supplier...

high quality warman slurry pump bearing assembly supplier 【high quality warman slurry pump bearing assembly supplier】

Read MoreDepending on the abrasive nature of the slurry, it is important to select the ideal seal. Slurry pump seals should have a hardened surface made of silicon carbide or tungsten carbide. Vortex pumps use patented seal technology that utilizes a double mechanical seal setup and a separate seal flushing system. This allows the sealing surface to be kept cool at all times without causing the slurry to overheat the seal and crack the surface.

high quality warman slurry pump bearing assembly supplier...

high quality warman slurry pump bearing assembly supplier 【high quality warman slurry pump bearing assembly supplier】

Read MoreFind a professional slurry pump supplier

high quality warman slurry pump bearing assembly supplier...

high quality warman slurry pump bearing assembly supplier 【high quality warman slurry pump bearing assembly supplier】

Read MoreFor more information about this new and improved pump, please contact us.

high quality warman slurry pump bearing assembly supplier...

high quality warman slurry pump bearing assembly supplier 【high quality warman slurry pump bearing assembly supplier】

Read MoreSelecting a dredge pump

high quality warman slurry pump bearing assembly supplier...

high quality warman slurry pump bearing assembly supplier 【high quality warman slurry pump bearing assembly supplier】

Read MoreIdeal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

high quality warman slurry pump bearing assembly supplier...

high quality warman slurry pump bearing assembly supplier 【high quality warman slurry pump bearing assembly supplier】

Read MoreIdeal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

high quality warman slurry pump bearing assembly supplier...

high quality warman slurry pump bearing assembly supplier 【high quality warman slurry pump bearing assembly supplier】

Read MoreSlurry Pump Impeller

high quality warman slurry pump bearing assembly supplier...

high quality warman slurry pump bearing assembly supplier 【high quality warman slurry pump bearing assembly supplier】

Read MorePacking the box seal

high quality warman slurry pump bearing assembly supplier...

high quality warman slurry pump bearing assembly supplier 【high quality warman slurry pump bearing assembly supplier】

Read MoreProcess speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

high quality warman slurry pump bearing assembly supplier...

high quality warman slurry pump bearing assembly supplier 【high quality warman slurry pump bearing assembly supplier】

Read More

Popular articles

- Although the focus of slurry pumps is often on the size and percentage of solids to be pumped, in many applications corrosion resistance is also an important factor in material selection. In such cases, the material chosen must provide adequate resistance to erosion and corrosion.

- If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right >pump. In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

- >Dredge Pump

- Examples of these dubious enhancements to impeller adjustment abound in the industry. One of these is the adjustable wear ring or suction liner to maintain the recommended clearance between the impeller front shroud and the throat bushing face. Almost all >slurry pumps, including AIER® slurry pumps, have features to ensure that this equipment specification can be maintained over time.

- Slurry Pump Selection

Latest articles

-

A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

-

Packing the box seal

-

If you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

-

Underwater installation

-

What we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. >Slurry pumps are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

-

Find the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

Links

Benefits of Using Control Boxes

- One of the key attributes of this tape is its remarkable temperature resistance. It can maintain its integrity and functionality in temperatures ranging from -55°C to 260°C, a feature that makes it suitable for both extreme cold and hot conditions. Whether you're dealing with refrigeration systems or high-temperature industrial machinery, the Seal It Silicone Insulation Tape ensures consistent performance.

- ,。、,,。,,,。,,。

- In conclusion, Flex Tape in white is a game-changer in the world of DIY repairs. With its unmatched strength, ease of use, versatility, and cost-effectiveness, this innovative product is the ultimate solution for all your repair needs. So why settle for anything less when you can have the best? Try Flex Tape in white today and experience the difference for yourself.

- Introduction

- In the realm of industrial plumbing and pipework, butyl tape serves as a thread sealant

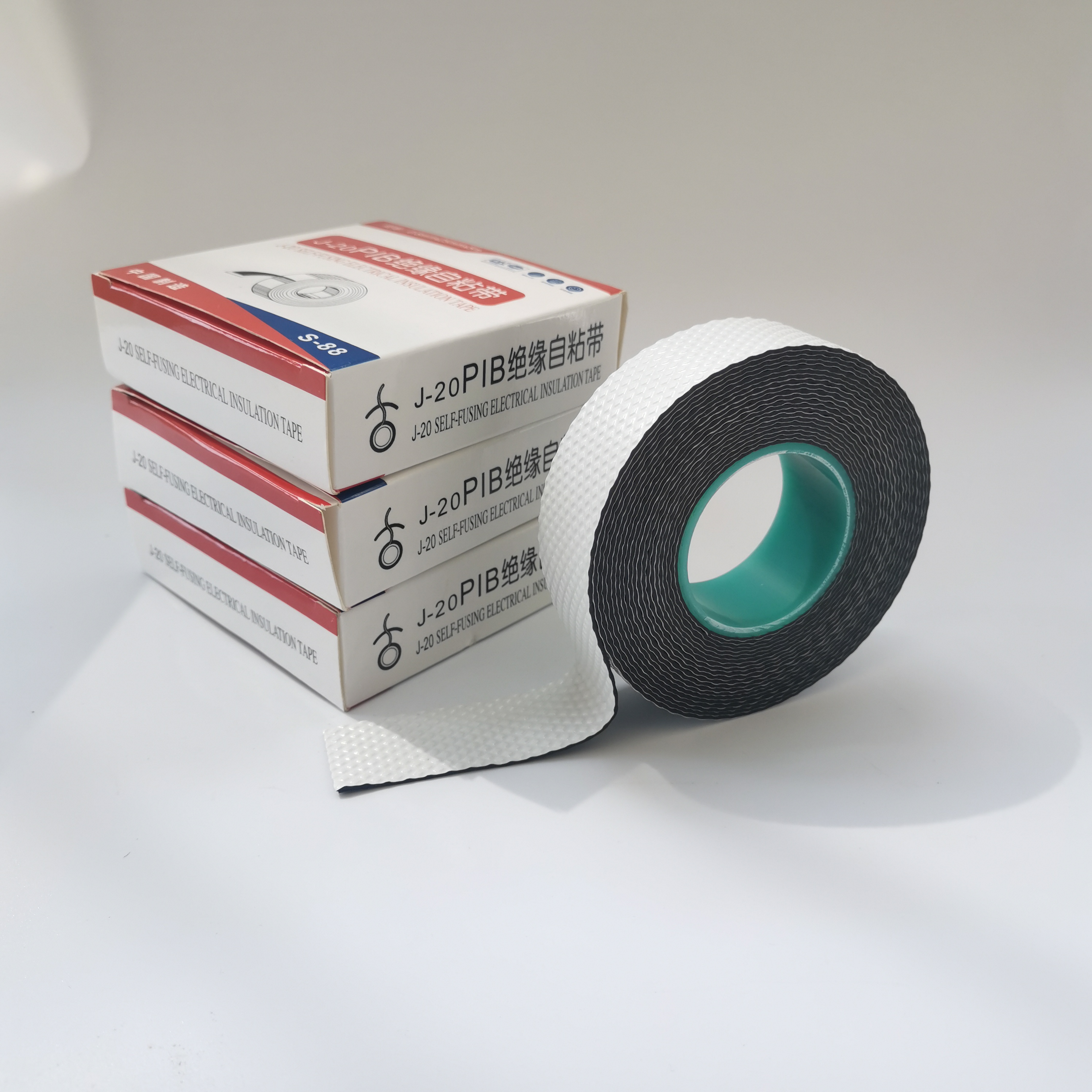

how to use self amalgamating tape. The tape's resistance to heat, oil, and other automotive fluids makes it a reliable option for repairing minor issues in a car or truck.

Its self-adhesive property eliminates the mess and complexity associated with using separate adhesives, saving time and effort in the process Its self-adhesive property eliminates the mess and complexity associated with using separate adhesives, saving time and effort in the process

Its self-adhesive property eliminates the mess and complexity associated with using separate adhesives, saving time and effort in the process Its self-adhesive property eliminates the mess and complexity associated with using separate adhesives, saving time and effort in the process self bonding rubber tape.

self bonding rubber tape.What is Butyl Rubber Sealant Tape?

Polyethylene Rubber Tape has several important characteristics:

1. Durability

super strong waterproof flex tape. Its flexibility also means it can be used in a variety of creative ways. Crafters use it for sturdy hinges on DIY projects, while athletes have been known to use it as a temporary fix for torn equipment. Gardeners love it for reinforcing plant ties, and it's a lifesaver for quick, emergency repairs on everything from camping gear to household items.

super strong waterproof flex tape. Its flexibility also means it can be used in a variety of creative ways. Crafters use it for sturdy hinges on DIY projects, while athletes have been known to use it as a temporary fix for torn equipment. Gardeners love it for reinforcing plant ties, and it's a lifesaver for quick, emergency repairs on everything from camping gear to household items.To remove it, simply make a cut along it lengthways and peel off the tape

Electrical tape is designed to adhere to wires, its tolerance for higher temperatures is a bit more resilient when compared to duct tape. Duct tape loses its stickiness and adhesive strength when exposed to high temperatures for a long time. If left long enough, the fibers duct tape uses for strength would eventually catch fire.

Moreover, fire-resistant drywall tape is typically made from materials including fiberglass and special polymers that enhance its performance during a fire. These materials can withstand higher temperatures and resist melting, which contributes to maintaining the integrity of the drywall installation. Builders and contractors are increasingly recognizing that investing in fire-resistant materials, including tape, is not just about compliance with codes but truly about prioritizing the safety of occupants.

fire resistant drywall tape