high quality pump for slurry factory

Latest articles

How much solids damage can the customer tolerate?

high quality pump for slurry factory...

high quality pump for slurry factory 【high quality pump for slurry factory】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

high quality pump for slurry factory...

high quality pump for slurry factory 【high quality pump for slurry factory】

Read MoreA variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right >pump. In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

high quality pump for slurry factory...

high quality pump for slurry factory 【high quality pump for slurry factory】

Read MoreOur firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

high quality pump for slurry factory...

high quality pump for slurry factory 【high quality pump for slurry factory】

Read MoreTraditionally, centrifugal pumps are used to pump highly abrasive slurries. Centrifugal pumps use the force generated by the rotating impeller to impinge kinetic energy into the slurry.

high quality pump for slurry factory...

high quality pump for slurry factory 【high quality pump for slurry factory】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

high quality pump for slurry factory...

high quality pump for slurry factory 【high quality pump for slurry factory】

Read MoreHow to Choose a Dredging Pump or Slurry Pump

high quality pump for slurry factory...

high quality pump for slurry factory 【high quality pump for slurry factory】

Read MoreTypical Applications of slurry pump

high quality pump for slurry factory...

high quality pump for slurry factory 【high quality pump for slurry factory】

Read MoreFor certain types of slurry pumping conditions, positive displacement pumps may be a more suitable option than centrifugal pumps.

high quality pump for slurry factory...

high quality pump for slurry factory 【high quality pump for slurry factory】

Read MoreMagnetite mixing

high quality pump for slurry factory...

high quality pump for slurry factory 【high quality pump for slurry factory】

Read More

Popular articles

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- The company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

- Selecting And Operating A Slurry Pump

- of a thick consistency, and.

- Examples of these dubious enhancements to impeller adjustment abound in the industry. One of these is the adjustable wear ring or suction liner to maintain the recommended clearance between the impeller front shroud and the throat bushing face. Almost all >slurry pumps, including AIER® slurry pumps, have features to ensure that this equipment specification can be maintained over time.

- As described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

Latest articles

-

Determine the perfect combination of slow pumping (to reduce wear) and fast pumping to prevent solids from settling and clogging.

-

In dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

-

Slurry Pump

-

The slurry weight or consistency determines the type, design and capacity of the slurry pump required. If you have any questions about the best pump for your application, welcome to >contact us today or request a quote.

-

Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

-

If the exact in-pump viscosity of the product is unknown, CSI can help

The versatility of flame retardant tapes extends beyond industrial uses. They are increasingly found in consumer products where additional safety measures are necessary. For example, these tapes can be used in the production of furniture, textiles, and even clothing, adding an extra layer of fire resistance. As consumers become more aware of safety issues related to fire hazards, the demand for flame retardant products, including tapes, is expected to rise.

High Voltage Busbar Insulation Tape Essential for Safety and Efficiency

The thickness of the tape you buy is an important consideration. Too thin, and your tape won’t be as durable, but too thick, and it’ll be difficult to install.

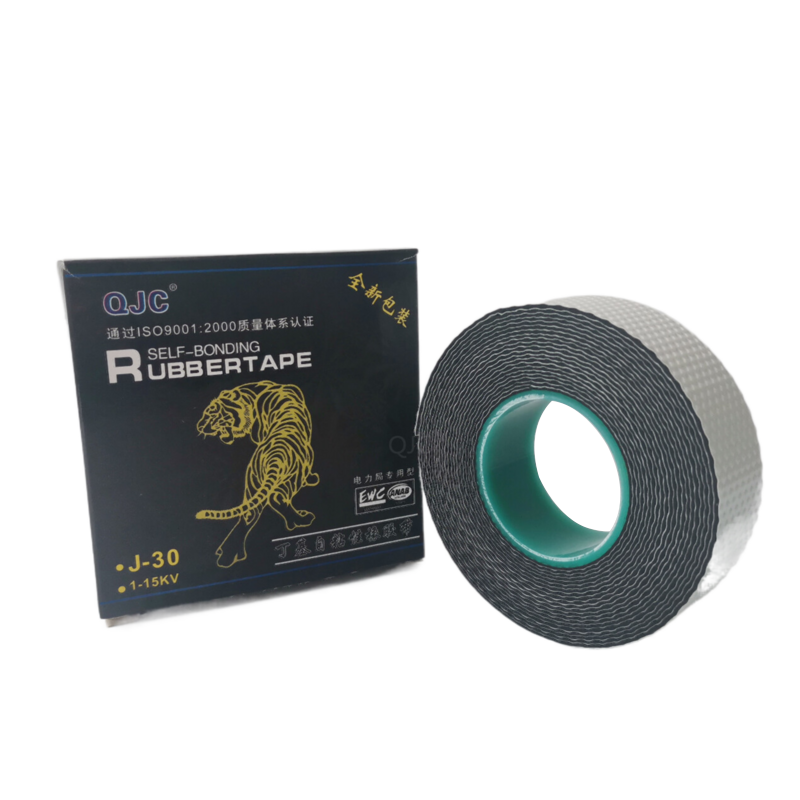

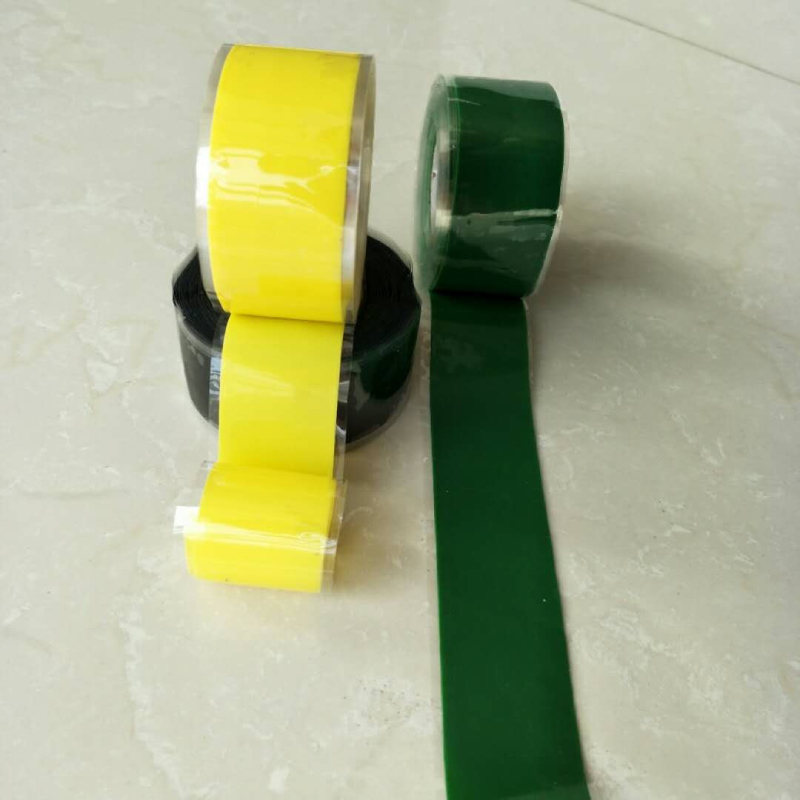

Electrical tapes are typically made with a polyvinylchloride (PVC) backing and a non-corrosive rubber-based adhesive. The backing is what gives it the ability to stretch and conform to cables and wiring. This stretch is a critical characteristic of electrical tapes because it allows the tape to wrap tightly around cables for long-lasting insulation. Most cloth, film, and other types of tapes do not possess the elongation characteristics that allow electrical tapes to function properly.

In electrical work, insulating strips are used to cover live wires, preventing accidental contact that could lead to short circuits or electric shock In electrical work, insulating strips are used to cover live wires, preventing accidental contact that could lead to short circuits or electric shock

In electrical work, insulating strips are used to cover live wires, preventing accidental contact that could lead to short circuits or electric shock In electrical work, insulating strips are used to cover live wires, preventing accidental contact that could lead to short circuits or electric shock insulating strip. In buildings, they can be seen lining windows and doors to reduce heat loss, improve energy efficiency, and enhance acoustic insulation.

insulating strip. In buildings, they can be seen lining windows and doors to reduce heat loss, improve energy efficiency, and enhance acoustic insulation.

self bonding rubber tape. Simply stretch the tape around the object, overlapping the layers to ensure a tight seal, and the adhesive properties of the tape will bond to itself, creating a strong, durable connection. The tape can be easily cut to size with scissors or a knife, making it customizable for any application.

flex tape black 4 in x 5 ft. Press down firmly to ensure a secure bond, and your repair is complete. There is no need for messy adhesives, complicated tools, or drying time – Flex Tape Black provides a quick and reliable solution to your repair needs.

In addition to its practicality, the tape's durability sets it apart from other insulation solutions. 3M HT Insulation Tape is resistant to abrasion, chemicals, and moisture, making it suitable for both indoor and outdoor use. This resilience ensures that it can withstand harsh environmental conditions without compromising its structural integrity. As a result, businesses can rely on this product to maintain operational efficiency and safety, even in challenging situations.

It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment

It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment It can be customized with different colors, patterns, or even company logos, adding a touch of style to the otherwise industrial-looking engine compartment wire harness automotive cloth tape.

wire harness automotive cloth tape.Butyl rubber is a heavy-duty adhesive that instantly adheres quickly and easily to most surfaces, even those like outside decks where moisture is a factor. Butyl tape is compatible with these surfaces:

Self fusing tape is a type of self-adhesive tape that can be used for emergency or temporary repairs to electrical wires, plumbing and hoses.