quality ceramic slurry pump factories

Latest articles

As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

quality ceramic slurry pump factories...

quality ceramic slurry pump factories 【quality ceramic slurry pump factories】

Read More1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

quality ceramic slurry pump factories...

quality ceramic slurry pump factories 【quality ceramic slurry pump factories】

Read MoreThere is a better way to pump sewage, overflows and other collected dirty water around the plant.

quality ceramic slurry pump factories...

quality ceramic slurry pump factories 【quality ceramic slurry pump factories】

Read MoreDischarge ports can be placed at 45 degree intervals and oriented in up to 8 different positions depending on your needs.

quality ceramic slurry pump factories...

quality ceramic slurry pump factories 【quality ceramic slurry pump factories】

Read MoreUnder ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

quality ceramic slurry pump factories...

quality ceramic slurry pump factories 【quality ceramic slurry pump factories】

Read MoreConveying medium

quality ceramic slurry pump factories...

quality ceramic slurry pump factories 【quality ceramic slurry pump factories】

Read MoreLarger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

quality ceramic slurry pump factories...

quality ceramic slurry pump factories 【quality ceramic slurry pump factories】

Read More>Vertical Slurry Pump

quality ceramic slurry pump factories...

quality ceramic slurry pump factories 【quality ceramic slurry pump factories】

Read More>Slurry Pump vs Mud Pump

quality ceramic slurry pump factories...

quality ceramic slurry pump factories 【quality ceramic slurry pump factories】

Read MoreConveying medium

quality ceramic slurry pump factories...

quality ceramic slurry pump factories 【quality ceramic slurry pump factories】

Read More

Popular articles

- Slurry Pump

- What is the best seal arrangement for the application?

- Selecting a dredge pump

- The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

- Using rubber as a wear lining material means

- How Slurry Pumps Differ From Standard Pumps?

Latest articles

-

factors-to-consider-when-choosing-a-slurry-pump

-

Slurry Pump VS Mud Pump

-

Many types of pumps are used for pumping slurries.The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a water-like liquid would move through a standard centrifugal pump.

-

Are the pump discharge components suitable for the slurry being pumped?

-

For more information about this new and improved pump, please contact us.

-

As this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

Links

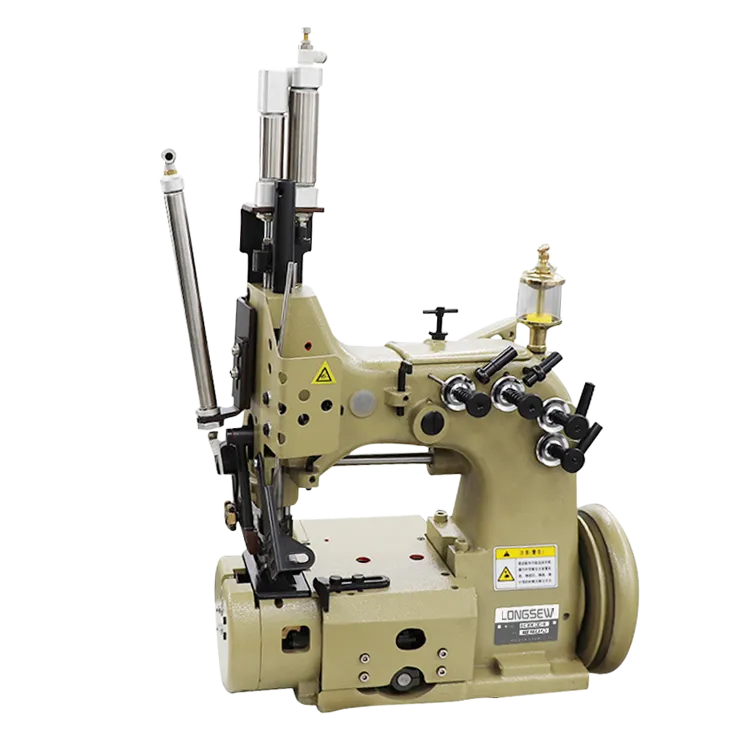

Maintenance and Care for Heavy Duty Sewing Machines

2. Walking Foot A walking foot is an essential feature when sewing vinyl, as it helps to evenly feed the material through the machine, reducing the chances of slipping and puckering. Some machines come with walking feet as standard, while others may require a separate purchase.

Canvas is a heavy, tightly woven fabric usually made of cotton, linen, or synthetic fibers. It makes tents, sails, backpacks, and art canvases. When working with such rigid materials, you need a heavy-duty sewing machine that can handle the thickness and strength of the cloth and ensure the stitches are always of good quality and work well. If you don’t use a heavy-duty sewing machine, you might have problems like broken needles, inconsistent stitching, strained motors, more wear and tear on a regular machine, and possible safety problems. All these things can make sewing frustrating and less than perfect.

Regular maintenance and operator training are essential for maximizing the performance of upholstery stitching machines. Proper care can extend the lifespan of these machines, ensuring that they continue to deliver high-quality results. Furthermore, training operators on the latest technologies and features helps in maintaining the productivity levels expected in today’s fast-paced manufacturing environments.

Not all hand crank sewing machines are created equal; choosing the right model is crucial for successful leatherwork. Artisans should look for machines specifically designed for heavy materials, with features such as adjustable presser foot pressure and robust needle systems.

Sewing has long been regarded as a valuable skill, allowing individuals to create beautiful garments, home décor, and more. However, the complexity of threading a sewing machine often deters beginners and seasoned crafters alike from diving into this rewarding hobby. Fortunately, the advent of self-threading sewing machines has simplified this process, making it easier than ever for anyone to unleash their creativity.

Conclusion

3. Cost-Effective Generally, chain stitch machines are more affordable than other types of industrial sewing machines. They consume less electricity, which translates to lower operating costs for businesses.

In the world of sewing, the zigzag sewing machine holds a special place due to its versatility and functionality. Whether you are a beginner, an experienced seamstress, or a professional tailor, zigzag sewing machines can significantly enhance your sewing capabilities. However, one of the primary considerations when investing in such a machine is its price. In this article, we will explore the factors that influence the pricing of zigzag sewing machines and provide insights into what you can expect in terms of cost.

Choosing the right heavy-duty sewing machine for thick leather can greatly enhance your sewing projects. With features tailored for strength, efficiency, and versatility, these machines are invaluable for both hobbyists and professional crafters. Take the time to assess your needs and explore your options, and you’ll find the perfect machine to help you bring your creative visions to life. Whether you’re making bags, garments, or home decor items, a heavy-duty sewing machine can be your best ally in achieving exceptional results.

The applications of zigzag sewing machines are endless. In garment construction, zigzag stitches are invaluable for finishing seams and hems. They can also be used for appliqué work, allowing sewists to attach fabric shapes onto a base fabric creatively. Additionally, for quilting, the zigzag stitch can add intricate designs or secure layers together.

Bulk bags are widely used in various industries, including agriculture, chemicals, pharmaceuticals, and food processing. They are designed to hold large volumes of granulated or powdered materials, providing a convenient and cost-effective solution for storage and transportation. Given their prevalent use, the demand for high-quality bulk bags has increased, leading to a corresponding rise in the need for efficient sewing solutions.

4. Improved Seam Strength The two rows of stitches provide additional security to seams, which is critical in ensuring that the garment withstands wear and tear. This reliability is essential as consumers increasingly demand durable products.

use of double needle sewing machine

1. Variability in Stitch Length Many models offer adjustable stitch length settings, enabling manufacturers to customize stitches according to the fabric type and design requirements.

Evolution of Automotive Sewing Machines

Conclusion

For those who prefer a more portable solution, the Janome Graceful Grey is a lightweight option that doesn’t compromise on features. This compact sewing machine features an automatic needle threader and has a simple interface that is accessible to all users. Its portability means you can take your sewing projects on the go, whether you’re heading to a sewing class or simply want to sew in a more comfortable setting.

The Art and Technology of Stitching Leather Machines

1. Automation and Efficiency

Understanding the Price of Single Needle Sewing Machines

The industrial walking foot machine stands as a testament to the advancements in textile manufacturing technology. It has revolutionized the way heavy fabrics are handled, enhanced production efficiency, and fostered innovation in design and sustainability. As textile industries continue to evolve, the walking foot machine will undoubtedly play a crucial role in shaping the future of fabric production, making it an indispensable asset in modern manufacturing environments. This technology not only streamlines the production process but also empowers workers and manufacturers to meet the dynamic challenges of the global market.

4. User-friendly Interface With advancements in technology, modern sewing machines often feature intuitive control panels, making them easier to operate and adjust for different fabrics and bag specifications.

Before you start sewing, you need to select the appropriate twin needle for your project. Twin needles are available in different widths (the distance between the two needles) and thicknesses. A wider spacing is ideal for techniques like pintucks, while a narrow spacing is better for sewing on knits and lightweight fabrics. Additionally, consider the size of the needle itself; a thicker needle is better for heavier fabrics like denim, while a finer needle works well with more delicate materials.

4. Metal Construction for Durability Hi-speed lockstitch machines are typically designed with sturdy metal bodies, ensuring longevity even under constant use in busy production environments.

2. Powerful Motor Beginner heavy-duty machines typically feature a more powerful motor, allowing them to sew through multiple layers of fabric or thicker materials without stalling.

Embroidery has long been a cherished art form, allowing individuals to express creativity and craftsmanship through fabric. With the advent of technology, the world of embroidery has evolved significantly, and one of the most innovative tools in this evolution is the zig zag embroidery machine. This sophisticated device is not only a time-saver but also a gateway to a myriad of design possibilities.

A pair of raw or selvage denim jeans is quite thick, requiring special attention during the sewing process. A heavy-duty sewing machine equipped with a strong motor and construction is essential for piercing through multiple layers of such dense material. This powerful machine is not just about brute force. It helps to maintain uniform stitch length and tension while sewing denim to prevent puckering and to ensure a clean, polished finish.