high quality good submersible slurry pump factory

Latest articles

Conveying medium

high quality good submersible slurry pump factory...

high quality good submersible slurry pump factory 【high quality good submersible slurry pump factory】

Read More2. All have vertical pumps and horizontal pumps and can convey slurry.

high quality good submersible slurry pump factory...

high quality good submersible slurry pump factory 【high quality good submersible slurry pump factory】

Read MoreFewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - usually 2-5 vanes.

high quality good submersible slurry pump factory...

high quality good submersible slurry pump factory 【high quality good submersible slurry pump factory】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

high quality good submersible slurry pump factory...

high quality good submersible slurry pump factory 【high quality good submersible slurry pump factory】

Read MoreCritical to the engineering of the pump are heavy duty bearing frames and shafts, extra thick wall sections and easily replaceable wear parts. Total life cycle cost considerations are critical when specifying pumps for severe operating conditions, such as FGD service. High chrome pumps are ideal due to the corrosive pH of the slurry.

high quality good submersible slurry pump factory...

high quality good submersible slurry pump factory 【high quality good submersible slurry pump factory】

Read MoreThe construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

high quality good submersible slurry pump factory...

high quality good submersible slurry pump factory 【high quality good submersible slurry pump factory】

Read MoreCarbon transfer

high quality good submersible slurry pump factory...

high quality good submersible slurry pump factory 【high quality good submersible slurry pump factory】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of , dredging pumps, is also increasing.

high quality good submersible slurry pump factory...

high quality good submersible slurry pump factory 【high quality good submersible slurry pump factory】

Read MoreThe first major requirement for >slurry pumps is to provide adequate service life. The erosive and corrosive effects of slurries, such as the impact of high velocity flow of liquid/solid mixtures, can be really challenging. In many applications, some of the solids in the mixture are larger than the particles normally specified; therefore, the pump should be able to pass through them without causing any damage or operational problems.

high quality good submersible slurry pump factory...

high quality good submersible slurry pump factory 【high quality good submersible slurry pump factory】

Read MoreSlurry pump power adjustment

high quality good submersible slurry pump factory...

high quality good submersible slurry pump factory 【high quality good submersible slurry pump factory】

Read More

Popular articles

- In a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

- Critical to the engineering of the pump are heavy duty bearing frames and shafts, extra thick wall sections and easily replaceable wear parts. Total life cycle cost considerations are critical when specifying pumps for severe operating conditions, such as FGD service. High chrome pumps are ideal due to the corrosive pH of the slurry.

- Step 4

- Many types of pumps are used for pumping slurries.The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a water-like liquid would move through a standard centrifugal pump.

- Materials of Construction

- Dredge pumps are designed to transfer large quantities of fluids and solids.

Latest articles

-

Caution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

-

One of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

-

Rubber Lined Slurry Pump

-

These mud pumps can pump not only sand, but also more mud. They are very effective in pumping all forms of mud, gravel, concrete, slurry, slush, etc.

-

Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

-

Rubber Lined Slurry Pump

Links

- Step 6 Smooth Out the Tape

- Applications of Automotive Electrical Tape Fabric

3M offers a variety of rubber electrical tapes, each with its unique features and applications. Here are a few of my favorites:

The electrical control box is the “nerve center” that helps coordinate and monitor all of these functions. A hydraulic control panel often includes automation equipment such as programmable logic controllers that monitor inputs and control outputs according to programmed rules.

- In healthcare, this innovative tape has found a niche in physiotherapy and sports medicine

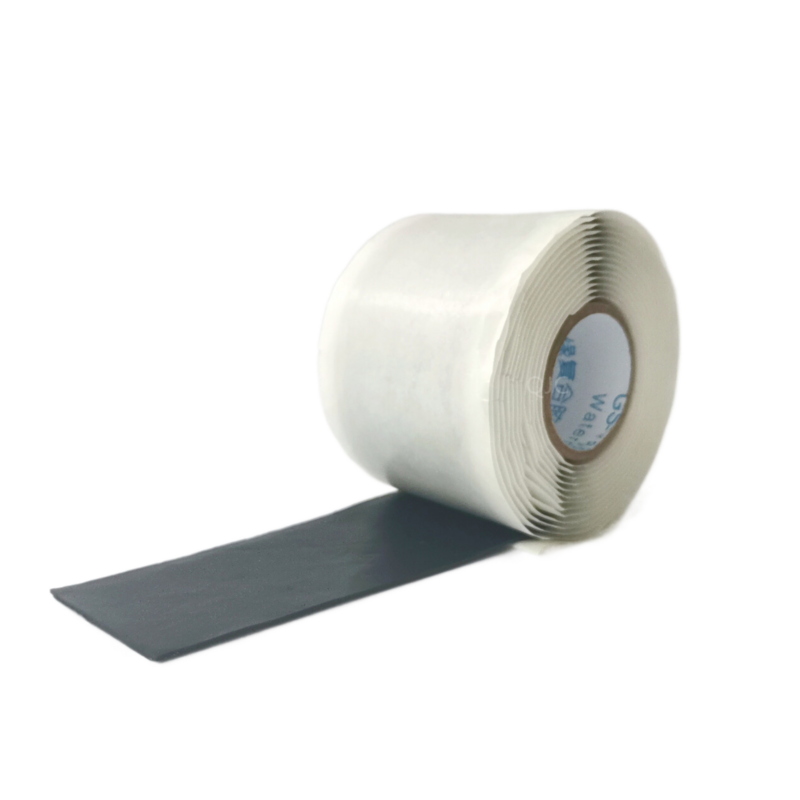

PlB self-amalgamating Tape

- In addition to its heat resistance, this type of tape is also known for its durability. It is designed to withstand wear and tear, providing long-lasting protection for electrical connections. This can help prevent the need for frequent repairs and replacements, saving time and money in the long run.

- Another advantage of safety floor tape is its durability. Unlike traditional paint markings, tape is designed to withstand heavy foot traffic, machinery, and other wear and tear. This means that the safety markings will remain visible and effective for a longer period of time, reducing the need for frequent reapplication. Additionally, safety floor tape is easy to install and remove, making it a cost-effective solution for maintaining safety in the workplace.

Generally speaking, manufacturers use three different adhesive types in combination with the backing material to produce a final “tape” product. Though these adhesive types can be subdivided into subgroups, the main categories are as follows:

- Non-flammable tape, also known as fire-retardant tape, is a type of adhesive tape that is specifically designed to be resistant to flames and high temperatures. This special tape is commonly used in a variety of industries where fire safety is a priority, such as construction, electrical, and automotive.

- In conclusion, fire-resistant foam tape is a powerful preventive measure against, enhancing safety in numerous sectors. Its ability to resist spread, provide insulation, and absorb sound makes it a valuable addition to any safety strategy. As technology continues to evolve, we can expect even more advanced and efficient fire-resistant solutions to emerge, further strengthening our defenses against potential fire disasters.

High Temperature Performance

- The tape's resistance to UV radiation, oxidation, and aging extends its service life, ensuring long-term reliability. It also demonstrates good chemical resistance, making it less susceptible to degradation when exposed to oils, solvents, and other chemicals. Furthermore, its ability to maintain its adhesive properties in low and high temperatures (-40°C to +120°C) makes it adaptable to a wide range of environments.

Another important aspect of safety floor tape is its durability and resistance to wear and tear. High-quality tape is designed to withstand heavy foot traffic, machinery, and various environmental conditions without losing its adhesive properties or becoming damaged. This ensures that safety markings remain intact and effective over time, reducing the need for frequent maintenance or replacement.

- High voltage rubber tape is made from a unique combination of materials, including synthetic rubber, which grants it its flexibility, and various insulating compounds that enhance its dielectric strength. The tape is typically thicker and more durable than regular electrical tape, making it suitable for applications where standard tape would quickly degrade or fail.

Insulating Motor Connections For Reliability

pink flagging tape.

At its simplest, a control box is an enclosure that houses electrical components such as switches, knobs, and controls. It’s the central point from which electrical circuits are managed, distributed, and protected. Think of it as the brain of an operation where the electrical nervous system can be coordinated with precision. In industrial applications, control boxes oversee the process of heavy machinery. In a residential context, they might regulate heating and cooling systems. The primary functions of a control box include:

The use of electronic enclosures for control boxes isn’t limited to industrial applications. Outdoor consumer electronics are more popular than ever, with many homeowners installing large and complex lighting and entertainment systems that turn any patio into a movie theater or dance floor. Naturally, this raises the problem of designing electronics that stand up to the elements.

black tack butyl. It comes in a convenient tube that allows you to apply the adhesive directly to the surface you want to bond. The tube is designed with a nozzle that allows you to control the flow of the adhesive, ensuring that you get just the right amount for your project.

black tack butyl. It comes in a convenient tube that allows you to apply the adhesive directly to the surface you want to bond. The tube is designed with a nozzle that allows you to control the flow of the adhesive, ensuring that you get just the right amount for your project.

What Does a Well Pump Control Box Do?

insulation tape.