high quality excavator dredge pump factories

Latest articles

From an operational point of view the stuffing box is different as it requires some leakage to ensure lubrication and to prevent heat build up. The mechanical seal box should be leak free.

high quality excavator dredge pump factories...

high quality excavator dredge pump factories 【high quality excavator dredge pump factories】

Read MoreAs described below, there are several >types of pumps that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

high quality excavator dredge pump factories...

high quality excavator dredge pump factories 【high quality excavator dredge pump factories】

Read Moretarget=_blank>Slurry Pump

high quality excavator dredge pump factories...

high quality excavator dredge pump factories 【high quality excavator dredge pump factories】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

high quality excavator dredge pump factories...

high quality excavator dredge pump factories 【high quality excavator dredge pump factories】

Read MoreA slurry is a mixture of fluids, which consists of a water-like liquid and particles. Typically, slurry acts in the same way as a viscous, sticky fluid - moving with gravity - but usually needs to be pumped.

high quality excavator dredge pump factories...

high quality excavator dredge pump factories 【high quality excavator dredge pump factories】

Read MoreIn a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

high quality excavator dredge pump factories...

high quality excavator dredge pump factories 【high quality excavator dredge pump factories】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

high quality excavator dredge pump factories...

high quality excavator dredge pump factories 【high quality excavator dredge pump factories】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

high quality excavator dredge pump factories...

high quality excavator dredge pump factories 【high quality excavator dredge pump factories】

Read MoreWhen slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

high quality excavator dredge pump factories...

high quality excavator dredge pump factories 【high quality excavator dredge pump factories】

Read MoreAdvantages of rubber

high quality excavator dredge pump factories...

high quality excavator dredge pump factories 【high quality excavator dredge pump factories】

Read More

Popular articles

- - Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

- Aier is pumping experts and offer some useful tips to maintain your >slurry pump.

- Choosing Dry Slurry Pumps Versus Submersible Slurry Pumps

- All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

- The length of the piping. The longer the pipe, the more slurry-induced friction the pump needs to overcome.

- Step 3

Latest articles

-

Depending on your own requirements, propeller seals, mechanical seals or packing seals can be used.

-

Corrosiveness of the slurry

-

How to Succeed in Slurry Pumping?

-

Typical Applications of slurry pump

-

Determine the nature of the material to be pumped

-

Consider the impeller. Slurry pumps must have thicker vanes than water pumps to prevent wear. Due to the increased thickness, there will be fewer vanes, otherwise the passages will be too narrow and will affect the performance of the pump. The impeller should have a large enough passage so that the largest solid particles can pass through without clogging.

Links

- One of the key benefits of HPMC is its versatility. It can be customized to meet specific requirements, allowing manufacturers to tailor their products to meet the needs of their customers. HPMC is also generally recognized as safe for use in food, personal care, and pharmaceutical applications, making it a popular choice among manufacturers and consumers alike.

Why is Hydroxypropyl Methylcellulose in Construction?

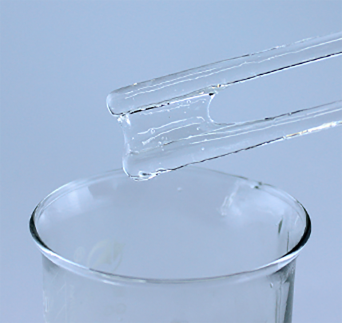

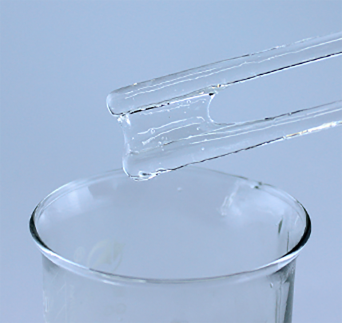

Appearance and Properties: White or quasi-white fibrous or granular powder

Major Producers:

The largest HPMC manufacturers are global chemical and pharmaceutical companies that have manufacturing capabilities in several countries. Among these, we can mention Dow Chemical Company, Ashland, and Shin-Etsu Chemical. These companies are known for their ability to produce high-quality HPMC suitable for a wide range of applications, including those requiring high standards such as the pharmaceutical and food industries.

Importance in the Gluten Free Food Industry:

In the context of gluten-free, the importance of HPMC has grown alongside the growing awareness and diagnosis of celiac disease and other gluten sensitivities. The need for gluten-free products that maintain the sensorial and structural qualities of traditional foods has driven the search for effective additives such as HPMC.

Current Considerations:

Although HPMC is widely used and generally considered safe, the current trend in the food industry is moving towards less processed and more natural ingredients. This may influence consumer perceptions of HPMC and other similar additives. However, its effectiveness as a gluten substitute in gluten-free preparations still makes it a valuable ingredient for many producers and consumers.

It is commonly used as a food additive to improve the texture and shelf-life of processed foods It is commonly used as a food additive to improve the texture and shelf-life of processed foods

It is commonly used as a food additive to improve the texture and shelf-life of processed foods It is commonly used as a food additive to improve the texture and shelf-life of processed foods hydroxypropyl methylcellulose uses. HPMC can be found in sauces, dressings, bakery products, and dairy alternatives. It acts as a thickener, emulsifier, and stabilizer, helping to create a smooth and creamy texture in products such as ice cream and yogurt.

hydroxypropyl methylcellulose uses. HPMC can be found in sauces, dressings, bakery products, and dairy alternatives. It acts as a thickener, emulsifier, and stabilizer, helping to create a smooth and creamy texture in products such as ice cream and yogurt.Celopro ME

HPMC is particularly effective at promoting disintegration in tablets containing drugs that are sensitive to moisture or heat HPMC is particularly effective at promoting disintegration in tablets containing drugs that are sensitive to moisture or heat

HPMC is particularly effective at promoting disintegration in tablets containing drugs that are sensitive to moisture or heat HPMC is particularly effective at promoting disintegration in tablets containing drugs that are sensitive to moisture or heat hydroxypropyl methylcellulose uses in tablets.

hydroxypropyl methylcellulose uses in tablets. This characteristic allows CMC to be used in liquid dosage forms such as suspensions, where it acts as a suspending agent preventing the active ingredients from settling This characteristic allows CMC to be used in liquid dosage forms such as suspensions, where it acts as a suspending agent preventing the active ingredients from settling

This characteristic allows CMC to be used in liquid dosage forms such as suspensions, where it acts as a suspending agent preventing the active ingredients from settling This characteristic allows CMC to be used in liquid dosage forms such as suspensions, where it acts as a suspending agent preventing the active ingredients from settling hpmc cmc. Moreover, CMC is also valued for its ability to stabilize emulsions, which are mixtures of two or more liquids that don't normally blend together, ensuring uniform distribution of the drug throughout the formulation.

hpmc cmc. Moreover, CMC is also valued for its ability to stabilize emulsions, which are mixtures of two or more liquids that don't normally blend together, ensuring uniform distribution of the drug throughout the formulation.