3 inch slurry pump factories

Latest articles

of a thick consistency, and.

3 inch slurry pump factories...

3 inch slurry pump factories 【3 inch slurry pump factories】

Read MoreA slurry is a mixture of fluids, which consists of a water-like liquid and particles. Typically, slurry acts in the same way as a viscous, sticky fluid - moving with gravity - but usually needs to be pumped.

3 inch slurry pump factories...

3 inch slurry pump factories 【3 inch slurry pump factories】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

3 inch slurry pump factories...

3 inch slurry pump factories 【3 inch slurry pump factories】

Read MoreAuxiliary equipment

3 inch slurry pump factories...

3 inch slurry pump factories 【3 inch slurry pump factories】

Read MoreBecause of these requirements, slurry pumps are usually larger than their clear liquid counterparts. In addition, it usually sacrifices efficiency, i.e. maximum efficiency and efficiency throughout its operating range, in exchange for the ability to achieve good operation in these challenging services.

3 inch slurry pump factories...

3 inch slurry pump factories 【3 inch slurry pump factories】

Read MoreHow to Choose a Dredging Pump or Slurry Pump

3 inch slurry pump factories...

3 inch slurry pump factories 【3 inch slurry pump factories】

Read MoreThe mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

3 inch slurry pump factories...

3 inch slurry pump factories 【3 inch slurry pump factories】

Read MoreSlurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

3 inch slurry pump factories...

3 inch slurry pump factories 【3 inch slurry pump factories】

Read MoreSlurry pump seals

3 inch slurry pump factories...

3 inch slurry pump factories 【3 inch slurry pump factories】

Read MoreWhat is the best seal arrangement for the application?

3 inch slurry pump factories...

3 inch slurry pump factories 【3 inch slurry pump factories】

Read More

Popular articles

- BCT Ceramic Slurry Pumps

- How to Choose a Dredging Pump or Slurry Pump

- Rubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

- What is 'slurry'?

- Rubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

- >Slurry Pump

Latest articles

-

Selecting a dredge pump

-

Pumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

-

If you have experience pumping slurries, you know it's not an easy task. Slurries are heavy and difficult to pump. They cause excessive wear on pumps and their components and are known to clog suction and discharge lines if not moving fast enough. Most importantly, it’s a challenge to make slurry pumps last for a reasonable amount of time. But, there are a few things you can do to extend the life of your slurry pump and make pumping slurry less of a challenge.

-

Step 2

-

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

-

Reduced inventory

Links

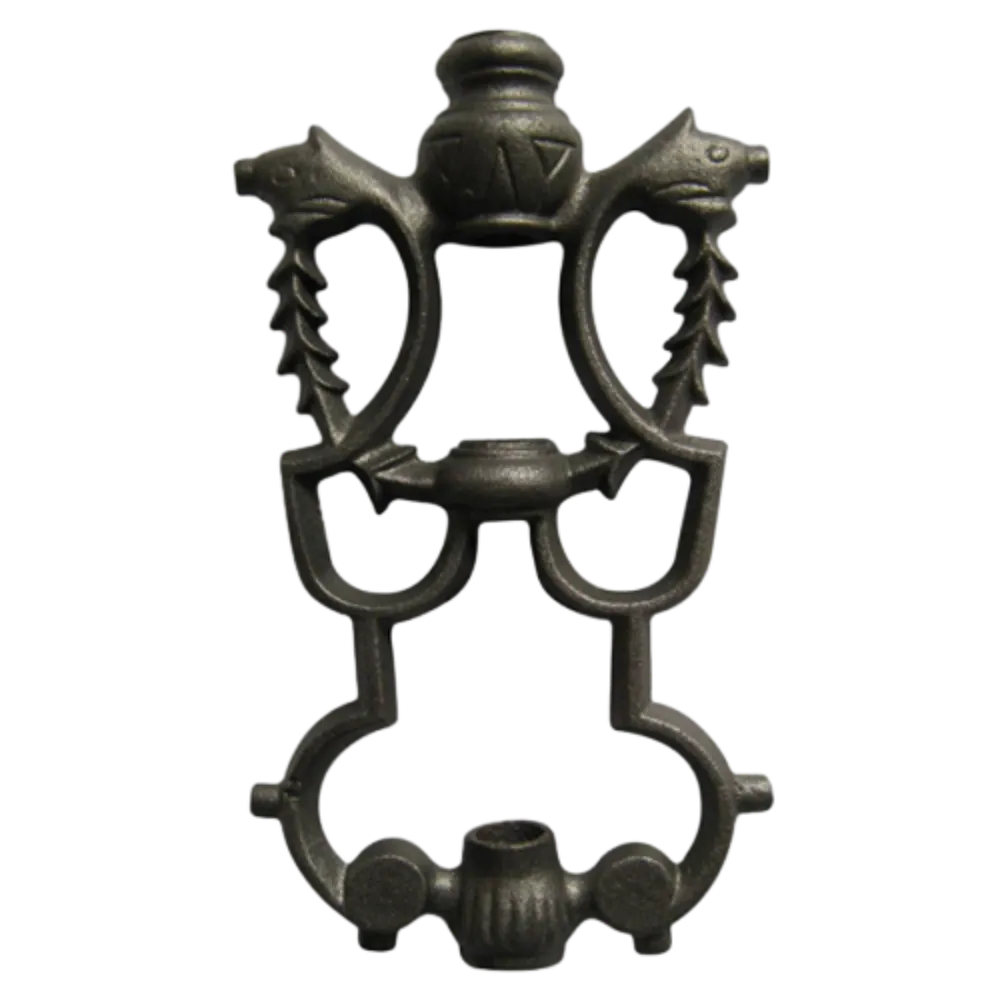

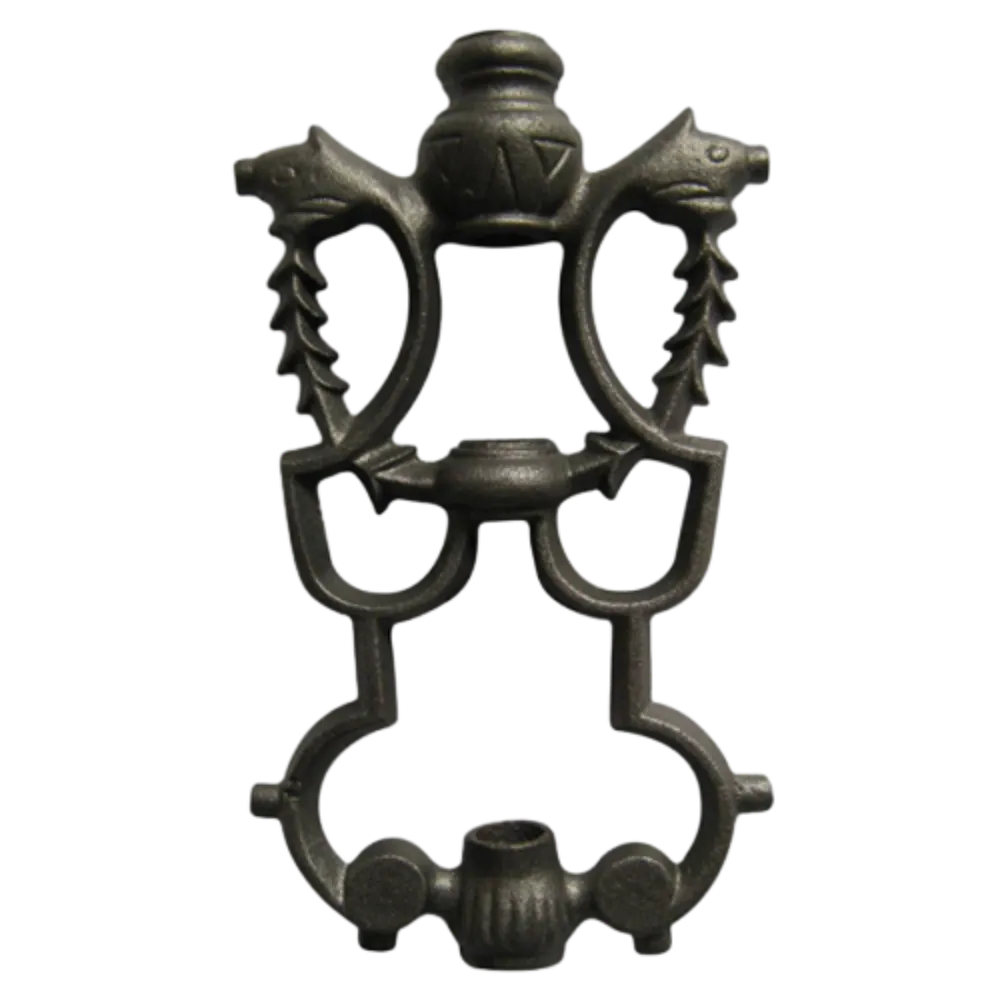

cast iron metal gates. Their solid construction and weight make them difficult to force open, providing peace of mind for homeowners. Furthermore, with proper maintenance, they can last for generations, acquiring a patina over time that only enhances their character.

cast iron metal gates. Their solid construction and weight make them difficult to force open, providing peace of mind for homeowners. Furthermore, with proper maintenance, they can last for generations, acquiring a patina over time that only enhances their character. They can be cleaned with mild soap and water, and occasional waxing can help to keep them looking like new They can be cleaned with mild soap and water, and occasional waxing can help to keep them looking like new

They can be cleaned with mild soap and water, and occasional waxing can help to keep them looking like new They can be cleaned with mild soap and water, and occasional waxing can help to keep them looking like new decorative cast iron panels. However, it's important to avoid using harsh chemicals or abrasive cleaners, as these can damage the surface of the panels.

decorative cast iron panels. However, it's important to avoid using harsh chemicals or abrasive cleaners, as these can damage the surface of the panels.At SHIJIAZHUANG TJJ TRADE CO.,LTD., we understand that quality matters, which is why we use only the finest materials and techniques in the manufacturing process. Each piece of cast iron furniture undergoes rigorous quality control to ensure its longevity and performance, allowing you to enjoy years of outdoor enjoyment with minimal maintenance.

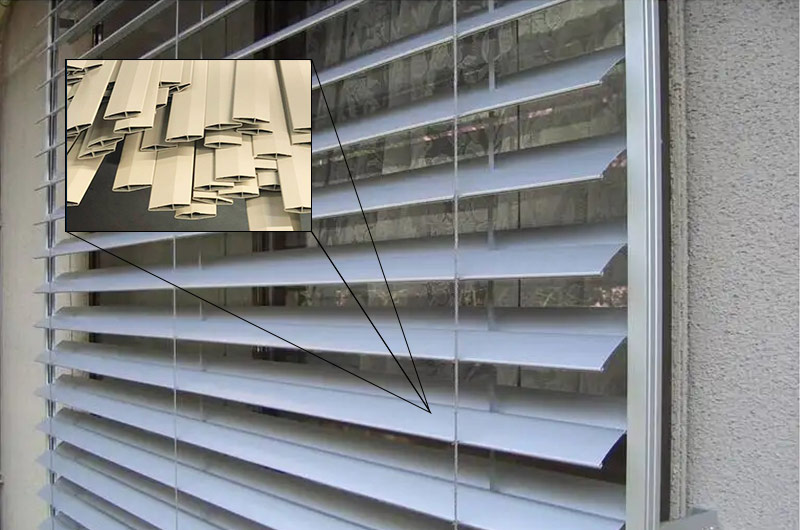

Because of the particularity of its surface treatment, aluminum alloy door and window profiles have strict requirements on product packaging and transportation.

The aluminum alloy profiles are made of new thermal insulation materials. A cold and hot bridge is formed between the inner and outer profiles to minimize the thermal conductivity of aluminum alloy and achieve good thermal and sound insulation effects.

It conjures images of bygone eras when trunks and chests were used to store treasures and memories It conjures images of bygone eras when trunks and chests were used to store treasures and memories

It conjures images of bygone eras when trunks and chests were used to store treasures and memories It conjures images of bygone eras when trunks and chests were used to store treasures and memories metal box with lid and lock. In a world increasingly dominated by digital storage, this physical container serves as a tangible link to the past, preserving our belongings in a way that feels intimate and personal.

metal box with lid and lock. In a world increasingly dominated by digital storage, this physical container serves as a tangible link to the past, preserving our belongings in a way that feels intimate and personal.However, there are certain situations where iron may be a better choice than steel. For example, cast iron is a type of iron that contains small amounts of carbon and other alloying elements, making it stronger and more wear-resistant than regular iron. Cast iron is commonly used in applications that require high strength and resistance to abrasion, such as engine blocks, cookware, and industrial machinery.

They are typically easy to install, often requiring just a few screws to attach them securely to the wall They are typically easy to install, often requiring just a few screws to attach them securely to the wall

They are typically easy to install, often requiring just a few screws to attach them securely to the wall They are typically easy to install, often requiring just a few screws to attach them securely to the wall steel thermostat lock box. Once in place, accessing the thermostat remains straightforward, ensuring you can still make necessary adjustments without hassle.

steel thermostat lock box. Once in place, accessing the thermostat remains straightforward, ensuring you can still make necessary adjustments without hassle.Also known as Hardcoat, it is relatively thick and denser than both chromic and sulfuric acid anodize.

Durable and Weather-Resistant

In other words, the actual cost of your ideal aluminum profiles for windows and doors is dependent on numerous factors, including the aforementioned ones.

stainless steel pull handles. Whether you’re opening a heavy door or pulling out a fully-loaded drawer, you can rely on stainless steel handles to provide a strong and sturdy grip.

The number one concern most folks have about an iron fence is rusting. The problem is that a lot of companies throw out a few vague terms you don’t know and assume you won’t ask questions. Even worst, some sites don’t really specify what type (if any) rust protection they have. Galvanization is a time-honored and great way to protect iron and steel from rust. Lots of fence makers will utilize e-coatings to minimize rust. While they can be effective, it is a thinner coating. We prefer hot-dip galvanization for our parts because it encapsulates every surface of the piece inside and out.

2. Rails