high quality oem metal lined slurry pump suppliers

Latest articles

If you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

high quality oem metal lined slurry pump suppliers...

high quality oem metal lined slurry pump suppliers 【high quality oem metal lined slurry pump suppliers】

Read MoreWhat is the best seal arrangement for the application?

high quality oem metal lined slurry pump suppliers...

high quality oem metal lined slurry pump suppliers 【high quality oem metal lined slurry pump suppliers】

Read MoreSlurry pump design

high quality oem metal lined slurry pump suppliers...

high quality oem metal lined slurry pump suppliers 【high quality oem metal lined slurry pump suppliers】

Read MoreAier is pumping experts and offer some useful tips to maintain your >slurry pump.

high quality oem metal lined slurry pump suppliers...

high quality oem metal lined slurry pump suppliers 【high quality oem metal lined slurry pump suppliers】

Read MoreThe main objective of all flush water programmes is to prevent contamination of the seals by pumped water.The flush water programme for boxes is therefore very similar to the flush water programme for mechanically sealed boxes. However there are still some obvious mechanical differences. The most notable difference is the addition of a seal (packing) between the inlet and outlet limits. This minimises the amount of flushing fluid consumed.

high quality oem metal lined slurry pump suppliers...

high quality oem metal lined slurry pump suppliers 【high quality oem metal lined slurry pump suppliers】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

high quality oem metal lined slurry pump suppliers...

high quality oem metal lined slurry pump suppliers 【high quality oem metal lined slurry pump suppliers】

Read More- By increasing the size of the worm housing, the speed at which the media moves is reduced. This lower velocity translates into lower wear.

high quality oem metal lined slurry pump suppliers...

high quality oem metal lined slurry pump suppliers 【high quality oem metal lined slurry pump suppliers】

Read MoreSlurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

high quality oem metal lined slurry pump suppliers...

high quality oem metal lined slurry pump suppliers 【high quality oem metal lined slurry pump suppliers】

Read MoreFind the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

high quality oem metal lined slurry pump suppliers...

high quality oem metal lined slurry pump suppliers 【high quality oem metal lined slurry pump suppliers】

Read MoreA clear clean fluid supplied from an external source is normally used which is delivered to the main sealing surface on the fluid side of the sealing process. By using a closed gap throat bushing, the stuffing box can be back-pressurised to a higher pressure, ensuring that the flushing fluid does not flash across the seal face.

high quality oem metal lined slurry pump suppliers...

high quality oem metal lined slurry pump suppliers 【high quality oem metal lined slurry pump suppliers】

Read More

Popular articles

- Auxiliary equipment

- Some quench seals are planned to replace the tight fitting outlet restriction with a secondary seal and a top outlet that can be piped to capture the used quench fluid and drain it from the rotating assembly. However the principle is the same, we try to cool the seal rather than flush it in any way.

- The Company Adopts Advanced Computer Aided Engineering Software

- Slurry Pump Impeller

- The FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

- >Dredge Pump

Latest articles

-

With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

-

If you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

-

target=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

-

- Keeping clean catch basins clean from solids

-

Applications

-

Slurry Pump

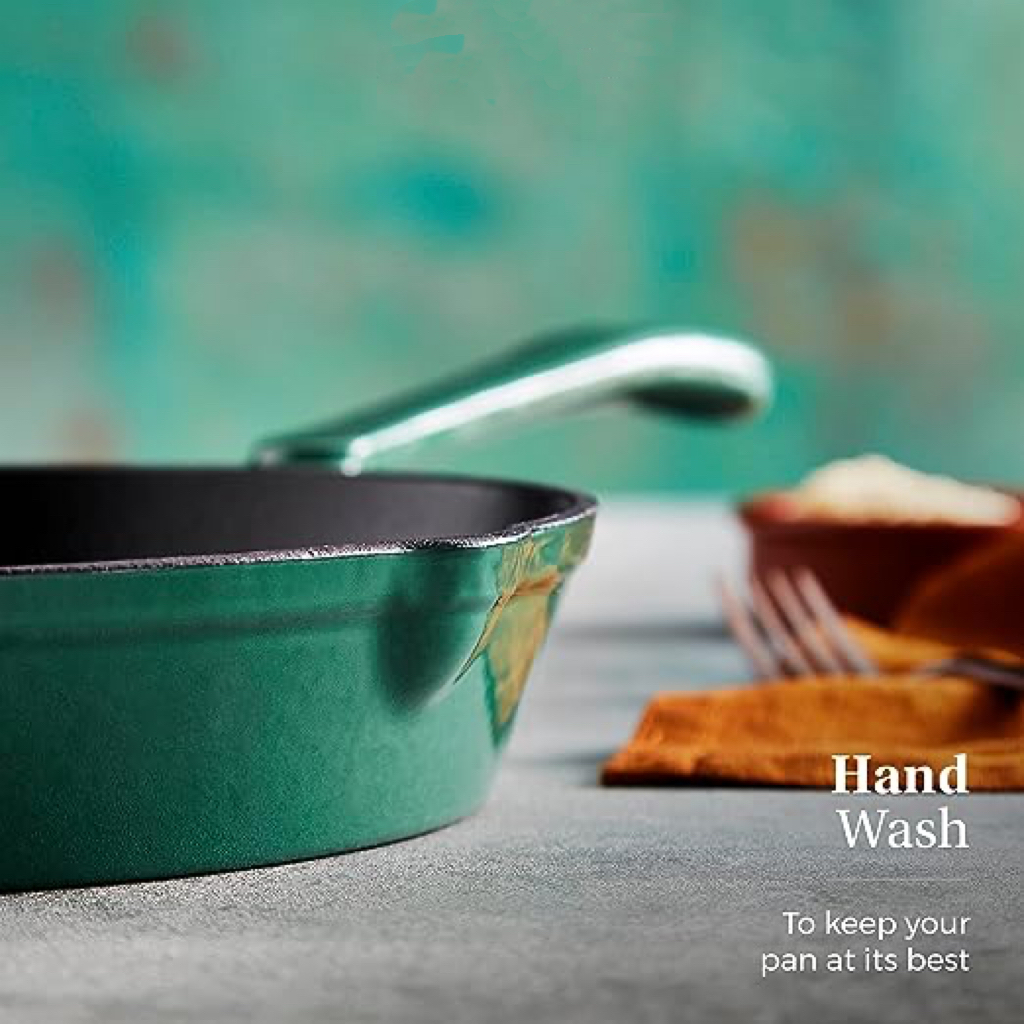

Enamel pots with lids are a versatile and essential addition to any kitchen. Whether you're cooking for a crowd or just a small meal for yourself, Enamel pots are a must-have for any home cook. Enamel pots with lids are many types of enamel pots with lids, including large enamel pots with lids, small enamel pots with lids, enameled cast iron pots with lids, etc. Each type has its own unique advantages and can be used for a variety of cooking tasks.

seasoned cast iron skillet for sale.

Ultimately, the type of frying pan you choose will depend on your individual cooking style, needs, and preferences. No matter which type you choose, a quality frying pan is an essential kitchen tool that will provide you with years of cooking enjoyment.

Ceramic cookware fares well when it comes to convenience, looks, and the ability to purchase in a set.

Finally, a frying pan is a flexible cooking vessel that you can use for sautéing, grilling, and baking, among other things.

Enamel pots are extremely durable and versatile kitchen tools, but they also need to be properly maintained and restored. Enameled cast iron can become worn or damaged during use, so restoring enameled cast iron becomes an important topic.

It can be used on the stovetop, in the oven, or even over an open flame It can be used on the stovetop, in the oven, or even over an open flame

It can be used on the stovetop, in the oven, or even over an open flame It can be used on the stovetop, in the oven, or even over an open flame Calphalon Enamel Cast Iron Braiser The deep, wide base of this braiser allows for both browning and simmering, making it an all-in-one cooking solution Calphalon Enamel Cast Iron Braiser The deep, wide base of this braiser allows for both browning and simmering, making it an all-in-one cooking solution

Calphalon Enamel Cast Iron Braiser The deep, wide base of this braiser allows for both browning and simmering, making it an all-in-one cooking solution Calphalon Enamel Cast Iron Braiser The deep, wide base of this braiser allows for both browning and simmering, making it an all-in-one cooking solution As the steak sizzles on the hot grill or pan, the bacon press is gently lowered onto it, exerting just the right pressure to keep the bacon in place while it cooks As the steak sizzles on the hot grill or pan, the bacon press is gently lowered onto it, exerting just the right pressure to keep the bacon in place while it cooks

As the steak sizzles on the hot grill or pan, the bacon press is gently lowered onto it, exerting just the right pressure to keep the bacon in place while it cooks As the steak sizzles on the hot grill or pan, the bacon press is gently lowered onto it, exerting just the right pressure to keep the bacon in place while it cooks Not only can you use it to grill meats and vegetables, but you can also use it to cook eggs, pancakes, and even bake bread Not only can you use it to grill meats and vegetables, but you can also use it to cook eggs, pancakes, and even bake bread

Not only can you use it to grill meats and vegetables, but you can also use it to cook eggs, pancakes, and even bake bread Not only can you use it to grill meats and vegetables, but you can also use it to cook eggs, pancakes, and even bake bread