8-6 rubber slurry pump supplier

Latest articles

Process speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

8-6 rubber slurry pump supplier...

8-6 rubber slurry pump supplier 【8-6 rubber slurry pump supplier】

Read MoreExpertise and experience

8-6 rubber slurry pump supplier...

8-6 rubber slurry pump supplier 【8-6 rubber slurry pump supplier】

Read Morehow-does-a-dredge-pump-work

8-6 rubber slurry pump supplier...

8-6 rubber slurry pump supplier 【8-6 rubber slurry pump supplier】

Read MorePositive displacement slurry pumps with limited capacity to deliver high head are used to pump slurry through pipes with very high solids concentrations.

8-6 rubber slurry pump supplier...

8-6 rubber slurry pump supplier 【8-6 rubber slurry pump supplier】

Read MoreCaution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

8-6 rubber slurry pump supplier...

8-6 rubber slurry pump supplier 【8-6 rubber slurry pump supplier】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

8-6 rubber slurry pump supplier...

8-6 rubber slurry pump supplier 【8-6 rubber slurry pump supplier】

Read MoreThere are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

8-6 rubber slurry pump supplier...

8-6 rubber slurry pump supplier 【8-6 rubber slurry pump supplier】

Read More600WN to 1000WN dredge pumps are of double casings, single stage cantilevered centrifugal pumps. These pumps are equipped with frame and lubrication is force thin oil. The design of double casing the pump working till the volute liner almost worn down and guarantee no leakage when volute liner is worn down.

8-6 rubber slurry pump supplier...

8-6 rubber slurry pump supplier 【8-6 rubber slurry pump supplier】

Read MoreMetal and/or rubber pump bushings are used to combat the erosion of solid particles found in the slurry. Metal slurry pump housings are usually made of carbide to resist erosion caused by increased pressure and circulation. Sometimes wear-resistant steel is used on the pump casing so that the pump can be welded if repairs are needed.

8-6 rubber slurry pump supplier...

8-6 rubber slurry pump supplier 【8-6 rubber slurry pump supplier】

Read MoreSlurry Pump

8-6 rubber slurry pump supplier...

8-6 rubber slurry pump supplier 【8-6 rubber slurry pump supplier】

Read More

Popular articles

- Typical Applications of slurry pump

- In dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

- A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

- There is a better way to pump sewage, overflows and other collected dirty water around the plant.

- Slurry Pump

- There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

Latest articles

-

Submersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

-

1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

-

Slurry Pump

-

Underwater installation

-

Pumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal target=_blank title=Slurry Pump>slurry pump. Let's talk about how slurry pumps differ from standard pumps and how to narrow your choices.

-

Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

Links

- The tradition of blue enamel cooking pots extends far beyond their modern usage. Historically, these pots were a symbol of durability and reliability, passed down through families as cherished heirlooms. Today, they continue to hold a special place in many homes, combining the charm of old-world cooking with the convenience of contemporary kitchenware.

- 1. Even cooking The press helps to flatten the bacon slices, ensuring that they cook evenly and achieve a crispy texture on both sides.

- The griddle meat press is not just for the outdoor chef; it's equally at home in the indoor kitchen. For those colder months when the grill is tucked away, a cast-iron griddle on the stove becomes the stage for culinary magic. Whether it's chicken cutlets or a thick pork chop, the press ensures an even thickness, which in turn guarantees even cooking. No more dried-out edges or undercooked centers—the meat press levels the playing field, so to speak.

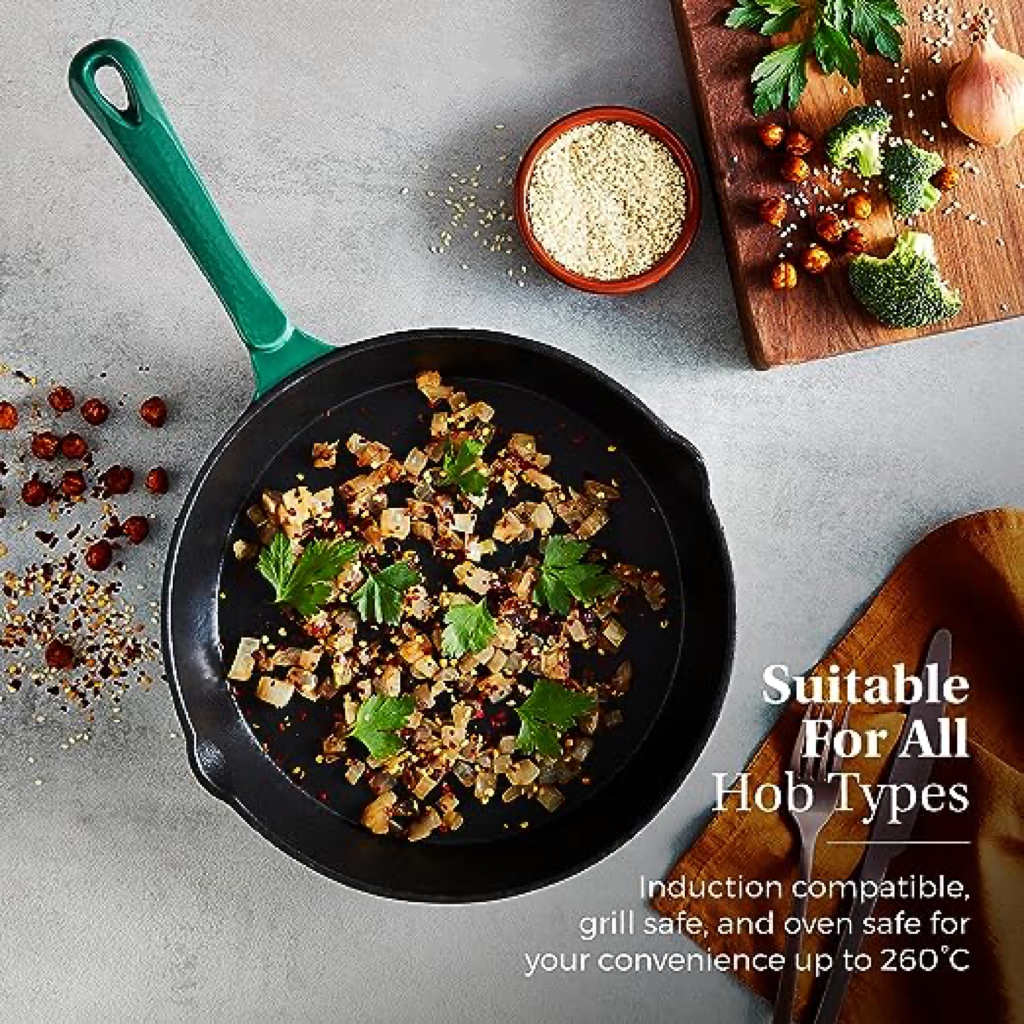

- In conclusion, the cast iron grill pan with cover is an indispensable tool for any outdoor chef. Its durable construction, even heat distribution, and versatility make it a must-have for anyone who enjoys grilling, frying, or baking outdoors. So why wait? Invest in a cast iron grill pan with cover and elevate your outdoor cooking game to new heights.

- In addition to their superior heat distribution, white enamel cookware sets are also incredibly easy to clean. The smooth enamel surface resists sticking and is non-porous, making it resistant to stains and odors. Simply rinse with warm, soapy water and wipe clean for hassle-free maintenance. Unlike traditional cast iron cookware, white enamel cookware sets do not require seasoning and are ready to use right out of the box.

- Stainless steel pans can handle very high temperatures—our Stainless Clad is oven-safe up to 800F.

- In the world of kitchen essentials, there lies a humble yet captivating item that has stood the test of time - the small enamel pot with lid. This seemingly simple culinary tool is more than just a cooking vessel; it's a testament to the marriage of functionality and aesthetics.

- Mini cast iron grill pan is a versatile kitchen tool that can be used for a variety of cooking tasks. Whether you want to sear a steak, grill vegetables, or even bake a small cake, this pan can handle it all. Its compact size makes it perfect for cooking small portions or for use in tight spaces, such as on a camping trip or in a dorm room.

- Moreover, iron cast enamel cookware is versatile enough to go from stove to table, seamlessly transitioning from cooking to serving

No, most professional chefs do not use non-stick cookware, especially non-stick fry pans. Before knowing why, let’s understand what non-stick cookware is. Non-stick cookware refers to utensils with surfaces from which the food simply slides off.

Typically, a layer of Teflon makes up the non-stick surface of a non-stick fry pan.

Restaurants don’t have non-stick pans as they do not match the basic demands of a busy kitchen. For a chef who has to send a dish out every two minutes, non-stick cookware is not a viable option as it wouldn’t last longer than a week.- Factors Affecting Iron Fry Pan Price

They remind us of the virtues of slowing down, taking the time to prepare meals with love, and savoring the experience of cooking as much as the food itself They remind us of the virtues of slowing down, taking the time to prepare meals with love, and savoring the experience of cooking as much as the food itself

They remind us of the virtues of slowing down, taking the time to prepare meals with love, and savoring the experience of cooking as much as the food itself They remind us of the virtues of slowing down, taking the time to prepare meals with love, and savoring the experience of cooking as much as the food itself cast iron cookware company.

cast iron cookware company.

From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style

From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style From classic white and pastels to bold, contemporary hues, there's a set to suit every taste and style enamel cook set. The enamel coating not only adds aesthetic appeal but also makes the cookware easy to clean, as it is generally dishwasher-safe.

enamel cook set. The enamel coating not only adds aesthetic appeal but also makes the cookware easy to clean, as it is generally dishwasher-safe.Chances are, your first piece of cookware was a non stick pan. This staple material is certainly beginner-friendly, but that doesn't mean it isn't just as useful in professional kitchens, too.

Although “skillet” is in the name, these vessels are not made of cast iron but instead of stainless steel, just like frying pans.

Stainless steel frying pans are also induction-ready. This means that they can be used on an induction cooker, which uses magnetic energy to heat the pan directly.

Another difference lies in how skillets usually come with a small helper handle on the other side for extra support. This is because skillets are often much heavier than frypans, so the extra support is always welcomed. Frypans usually come with a single handle, but there are rare occasions where it may come with a helper handle for larger ones.

From sautéing vegetables to searing steaks, the high walls of the skillet contain splatters and allow for a measure of depth that makes stirring and tossing a breeze From sautéing vegetables to searing steaks, the high walls of the skillet contain splatters and allow for a measure of depth that makes stirring and tossing a breeze

From sautéing vegetables to searing steaks, the high walls of the skillet contain splatters and allow for a measure of depth that makes stirring and tossing a breeze From sautéing vegetables to searing steaks, the high walls of the skillet contain splatters and allow for a measure of depth that makes stirring and tossing a breeze round skillet. Moreover, the broad surface area is ideal for pan-frying or making large batches of sauces and gravies.

round skillet. Moreover, the broad surface area is ideal for pan-frying or making large batches of sauces and gravies.Whereas kitchen enthusiasts and cooking professionals who chose the skillet will enjoy the versatility, near indestructible durability, and in turn the longevity offered by the skillet. Ultimately, one is only better than the other depending on the lifestyle you lead.

With just a little bit of care, these skillets can develop a natural patina that makes cooking without oils or fats possible With just a little bit of care, these skillets can develop a natural patina that makes cooking without oils or fats possible

With just a little bit of care, these skillets can develop a natural patina that makes cooking without oils or fats possible With just a little bit of care, these skillets can develop a natural patina that makes cooking without oils or fats possible iron skillets for sale. This feature is particularly beneficial for those who want to reduce their fat intake while enjoying delicious meals.

iron skillets for sale. This feature is particularly beneficial for those who want to reduce their fat intake while enjoying delicious meals.The benefit of a French skillet is that it is ideal for frying large quantities of food or making stews and sauces that require simmering. Its higher straight sides make it easier to cook with more liquid, while its broader base allows for even heat distribution. French skillets are versatile and can be used for various cooking tasks.

Another reason chefs reach for our Non Stick is for quickly cooking pasta. They’re able to add the sauce into the pan, followed by the noodles, then emulsify it together for a glossy finish. The superior non stick surface of our pans means nothing sticks and all the sauce ends up on your plate, rather than in the pan.