fgd pump factories

Latest articles

Dredge pumps are designed to transfer large quantities of fluids and solids.

fgd pump factories...

fgd pump factories 【fgd pump factories】

Read MoreIn addition, a new level of complexity is added to an otherwise simple machine. Other parts must now be inventoried and training beyond basic spanner turning is required. When it comes to pumping rock and some of the world's most abrasive materials.

fgd pump factories...

fgd pump factories 【fgd pump factories】

Read MoreDetermine the size of the pump

fgd pump factories...

fgd pump factories 【fgd pump factories】

Read MoreSlurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

fgd pump factories...

fgd pump factories 【fgd pump factories】

Read MoreSubmersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

fgd pump factories...

fgd pump factories 【fgd pump factories】

Read MoreTo reduce wear, reduce the pump discharge pressure to the lowest possible point.

fgd pump factories...

fgd pump factories 【fgd pump factories】

Read MoreSlurry pipe diameter.

fgd pump factories...

fgd pump factories 【fgd pump factories】

Read MoreLess downtime

fgd pump factories...

fgd pump factories 【fgd pump factories】

Read More>Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

fgd pump factories...

fgd pump factories 【fgd pump factories】

Read MoreAll manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

fgd pump factories...

fgd pump factories 【fgd pump factories】

Read More

Popular articles

- Typically, slurries are.

- Step 2

- Depending on your own requirements, propeller seals, mechanical seals or packing seals can be used.

- Natural rubber is an excellent wear material when handling wet sand slurries. Its strength, resilience and cut resistance have a positive impact on the wear performance of slurry pumps.

- A typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

- Sites often rely on centrifugal pumps to provide slurry service. These pumps (and their associated piping systems) require special provisions that demand detailed knowledge of the properties of solids and slurries to prevent wear, corrosion, erosion and other adverse effects such as solids settling. Specifying the optimum combination of speed, geometry and material requires a proper balance of often conflicting pump priorities; this requires consideration of stable operation, maximum wear life, operational flexibility and minimum energy consumption.

Latest articles

-

Customised solutions

-

The same point of slurry pump and mud pump

-

If you want to get more information about the slurry pump for sale, welcome to target=_blank title=Contact Us>contact us.

-

Slurry Pump Impeller

-

The slurry weight or consistency determines the type, design and capacity of the slurry pump required. If you have any questions about the best pump for your application, welcome to >contact us today or request a quote.

-

Centrifugal slurry pumps capable of providing high capacity with a limited head are mainly used for pumping slurry through pipes with a concentration of less than 70% by weight of solids. Centrifugal slurry pumps can be vertical, horizontal or submersible.

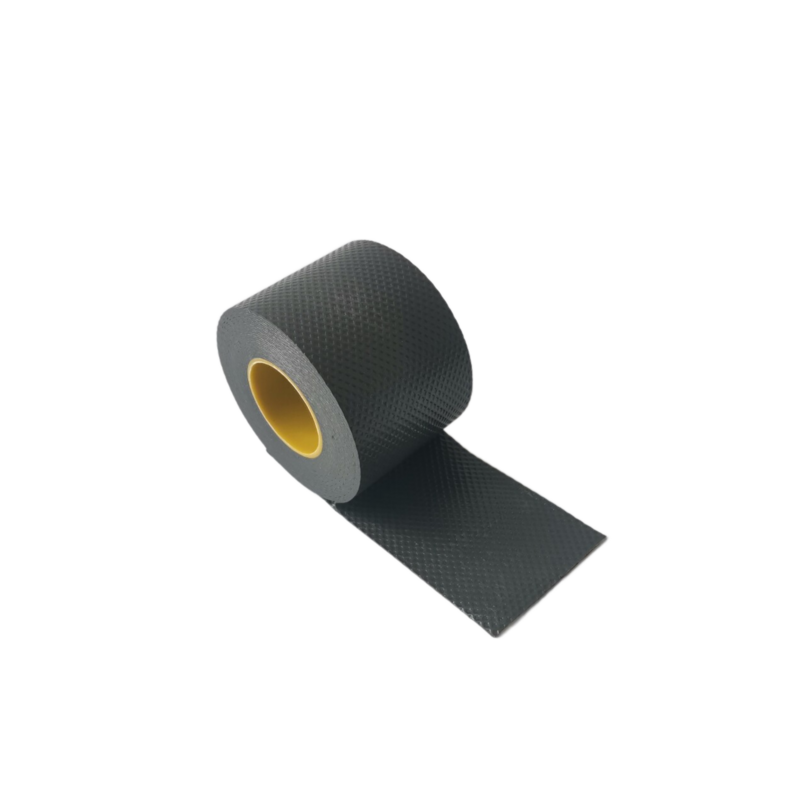

The Versatile Utility of PVC Black Tape

Applications for Butyl Rubber Sealant Tape

Moreover, many industries are subject to regulatory compliance regarding safety protocols. The use of temporary floor marking tape can help businesses adhere to these regulations by clearly marking areas that require attention. This is particularly important in warehouses and manufacturing facilities, where the movement of heavy machinery and foot traffic can lead to accidents if not properly managed.

Its self-adhesive nature ensures a strong bond instantly, eliminating the need for additional adhesives or curing processes Its self-adhesive nature ensures a strong bond instantly, eliminating the need for additional adhesives or curing processes

Its self-adhesive nature ensures a strong bond instantly, eliminating the need for additional adhesives or curing processes Its self-adhesive nature ensures a strong bond instantly, eliminating the need for additional adhesives or curing processes 130c linerless rubber splicing tape. This not only streamlines production but also enhances productivity.

130c linerless rubber splicing tape. This not only streamlines production but also enhances productivity.Moreover, butyl rubber tape is non-toxic and safe for use in various applications, including food-related contexts. This makes it a great choice for sealing appliances, packaging, or other areas where food safety is a concern. Its versatility extends to a range of industries, including automotive, construction, electronics, and more.

self vulcanizing tape. It is employed to repair and protect pipes, tanks, and other structures from corrosion and damage. The tape's ability to adhere tightly to various surfaces, even in the presence of moisture or extreme temperatures, makes it an invaluable asset for contractors and maintenance personnel.

self vulcanizing tape. It is employed to repair and protect pipes, tanks, and other structures from corrosion and damage. The tape's ability to adhere tightly to various surfaces, even in the presence of moisture or extreme temperatures, makes it an invaluable asset for contractors and maintenance personnel.