slurry pump chinese supplier

Latest articles

When pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

slurry pump chinese supplier...

slurry pump chinese supplier 【slurry pump chinese supplier】

Read MoreCorrosiveness of the slurry

slurry pump chinese supplier...

slurry pump chinese supplier 【slurry pump chinese supplier】

Read MorePacking the box seal

slurry pump chinese supplier...

slurry pump chinese supplier 【slurry pump chinese supplier】

Read MoreThe slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

slurry pump chinese supplier...

slurry pump chinese supplier 【slurry pump chinese supplier】

Read More- Installation flexibility - The submersible slurry pump is available in a variety of mounting models, including portable and semi-permanent (also easy to move as it can be freely suspended from a chain or similar device without having to be bolted to the ground/floor, etc.).

slurry pump chinese supplier...

slurry pump chinese supplier 【slurry pump chinese supplier】

Read MoreIn dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

slurry pump chinese supplier...

slurry pump chinese supplier 【slurry pump chinese supplier】

Read MoreWhat is the pump constructed of?

slurry pump chinese supplier...

slurry pump chinese supplier 【slurry pump chinese supplier】

Read MoreA slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

slurry pump chinese supplier...

slurry pump chinese supplier 【slurry pump chinese supplier】

Read MoreThese conditions include

slurry pump chinese supplier...

slurry pump chinese supplier 【slurry pump chinese supplier】

Read MoreIt is important that the pump you choose has components that will not wear out from abrasive slurries.

slurry pump chinese supplier...

slurry pump chinese supplier 【slurry pump chinese supplier】

Read More

Popular articles

- With the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

- Selecting a dredge pump

- Firstly, analysing your duty helps us to determine whether you are using the type and size of pump best suited to your needs. Cavitation can occur due to surges; a very effective way to solve this problem is to install a choke on the pump head to increase the pressure on the casing, which then absorbs the surge, or to add a choke to the output to reduce the surge.

- Types of damage to slurry pumps

- If you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

- Consideration should be given to installing mixers on guide rods in the catch basin/tank to keep solids in suspension and avoid settling in the catch basin/tank. When investing in a slurry pump, you want to pump slurry that includes solids, not just dirty water. Therefore, it is important to make sure that the pump is doing this; by using an agitator, the pump is fed with solids and pumping the slurry.

Latest articles

-

Dredge pumps are designed to transfer large quantities of fluids and solids.

-

The concept of the >slurry pump and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

-

Slurry pumps are usually larger than standard pumps, have more horsepower and use stronger bearings and shafts. The most common >type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids pass through a standard centrifugal pump.

-

Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

-

We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

-

What is slurry?

Links

- * Parking lots To mark out pedestrian crossings, parking spaces, and emergency vehicle access routes.

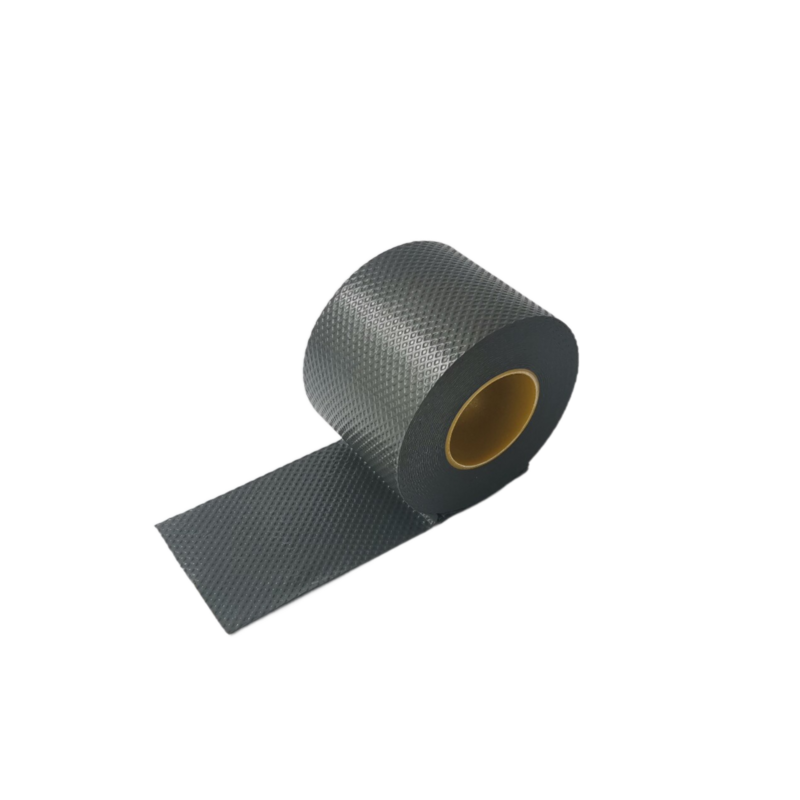

- One of the key benefits of fireproof tape is its ability to create a seal around doors, windows, vents, and other openings in a building. By applying this tape to these vulnerable areas, you can prevent hot air and flames from entering or escaping, helping to contain a fire within a specific area.

- Surface Protection

Seal out moisture from electrical connections

- Another key feature of this tape is its electrical insulating properties. It is designed to prevent the flow of electricity between connected wires, ensuring the safety of both the vehicle and its occupants. This is particularly important in automotive applications where electrical systems are critical to the proper functioning of the vehicle.

Common Applications

- Another advantage of automotive wire wrap tape is its ability to provide a secure and tight grip on the wires. This helps to prevent the wires from coming loose or becoming tangled, which can lead to electrical malfunctions or even fires. The tape also helps to reduce the risk of abrasion and wear on the wires, extending their lifespan and improving overall performance.

- Flexibility and Conformability: Rubber adhesives remain flexible and conformable even after application. This allows the tape to adhere well to irregular or uneven surfaces, ensuring a tight and secure bond. The flexibility of the rubber adhesive enables it to accommodate movement or slight variations in the bonded surfaces.

However, it is also essential to consider the limitations of Black Flex Tape. While it offers excellent short-term and mid-term solutions, it may not always be suitable for long-term structural repairs. In cases where heavy-duty strength and durability are required, additional methods or materials might still be necessary. Though it excels at providing temporary fixes, users should remain mindful of the contexts in which they are applying it.

- In the bustling world of industry, safety is paramount. One essential aspect that contributes significantly to workplace safety is the use of industrial floor marking tape. This versatile and cost-effective solution is designed to guide workers, identify hazards, and promote efficient workflow within factories, warehouses, and other industrial settings.

- Automotive electrical tape fabric is typically made from high-quality materials that are resistant to heat, moisture, chemicals, and abrasion. These properties make it ideal for use in harsh automotive environments where exposure to extreme temperatures, moisture, and chemicals is common. The tape is also designed to be flexible and easy to handle, making it simple to apply and remove without damaging the underlying surfaces.

Choosing a Control Box

3. Peel and stick.Butyl sealant tape usually comes with a protective backing to prevent it from sticking to itself during storage and handling. Carefully peel off the backing to expose the adhesive side of the tape. Position the adhesive side of the tape on the surface, and carefully align it with the area to be sealed.

But there is more. Pros know that rubber tapes can offer more than just high voltage insulation and are often used in a variety of low voltage applications as well.

high voltage rubber tape. Cable repair High-voltage rubber tape can be used to repair damaged cables by covering the damaged area and providing a temporary or permanent solution.

high voltage rubber tape. Cable repair High-voltage rubber tape can be used to repair damaged cables by covering the damaged area and providing a temporary or permanent solution.3. Flexibility and Adaptability Butyl rubber is inherently flexible, allowing it to be easily installed and conformed to various roofing shapes and structures. This adaptability makes butyl rubber sheets suitable for both flat and sloped roofs, providing a reliable solution for architects and builders working on diverse projects.

These membranes are easy to install, requiring minimal expertise and tools, thus reducing labor costs and project timelines These membranes are easy to install, requiring minimal expertise and tools, thus reducing labor costs and project timelines

These membranes are easy to install, requiring minimal expertise and tools, thus reducing labor costs and project timelines These membranes are easy to install, requiring minimal expertise and tools, thus reducing labor costs and project timelines butyl rubber waterproofing. They are also environmentally friendly, as they are non-toxic and can be recycled, aligning with sustainable building practices.

butyl rubber waterproofing. They are also environmentally friendly, as they are non-toxic and can be recycled, aligning with sustainable building practices.