china heavy duty slurry pump

Latest articles

Slurry Pump

china heavy duty slurry pump...

china heavy duty slurry pump 【china heavy duty slurry pump】

Read MoreIf you've ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. There's no doubt that the slurry on the pump is hard. But the more you know about what's being pumped, the better your pump selection will be, resulting in longer mean time between failures. Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share the following content with you.

china heavy duty slurry pump...

china heavy duty slurry pump 【china heavy duty slurry pump】

Read MorePumping slurry can be a challenging problem, but with the right instruction, pumping and maintenance plan, you will achieve operational success.

china heavy duty slurry pump...

china heavy duty slurry pump 【china heavy duty slurry pump】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

china heavy duty slurry pump...

china heavy duty slurry pump 【china heavy duty slurry pump】

Read Morehow-does-a-dredge-pump-work

china heavy duty slurry pump...

china heavy duty slurry pump 【china heavy duty slurry pump】

Read More1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

china heavy duty slurry pump...

china heavy duty slurry pump 【china heavy duty slurry pump】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

china heavy duty slurry pump...

china heavy duty slurry pump 【china heavy duty slurry pump】

Read MoreChoosing the Right Pump for Flue Gas Desulphurisation

china heavy duty slurry pump...

china heavy duty slurry pump 【china heavy duty slurry pump】

Read MoreWhat is a dredging pump?

china heavy duty slurry pump...

china heavy duty slurry pump 【china heavy duty slurry pump】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

china heavy duty slurry pump...

china heavy duty slurry pump 【china heavy duty slurry pump】

Read More

Popular articles

- TL FGD Pump

- Conveying medium

- Safety

- There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

- One of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

- For certain types of slurry pumping conditions, positive displacement pumps may be a more suitable option than centrifugal pumps.

Latest articles

-

A slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

-

Discharge ports can be placed at 45 degree intervals and oriented in up to 8 different positions depending on your needs.

-

The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

-

Dry Installation

-

Dredge Pump

-

A slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

Links

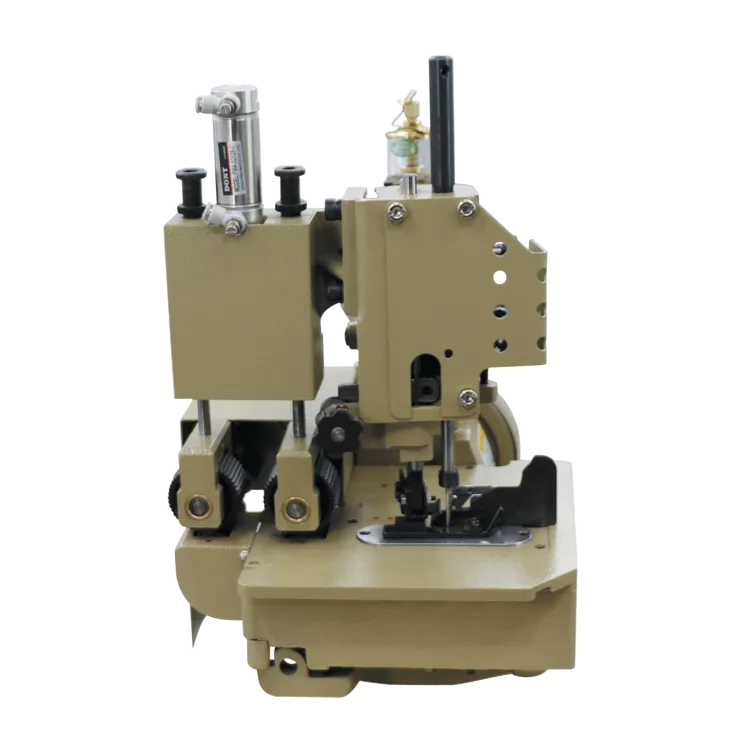

The 2% needle industrial sewing machine is a powerful and reliable machine that is suitable for a wide range of sewing tasks. Its ability to use two needles simultaneously allows for greater flexibility in sewing different types of fabrics and materials. This machine is perfect for sewing projects that require a high level of accuracy and attention to detail.

2. Enhanced Design Options The ability to embroider complex designs with multiple colors simultaneously gives businesses a competitive edge, enabling them to offer customers a wider range of products.

The Evolution and Importance of Industrial Walking Foot Sewing Machines

The Future of Climbing Rope Manufacturing

Understanding PP Woven Bags

The art of sailmaking is a time-honored craft that has evolved over centuries, yet its reliance on quality tools has remained steadfast. Among these tools, the sailmaker sewing machine stands out as an indispensable asset for anyone involved in creating and repairing sails for boats, yachts, and even large ships. This specialized sewing machine is designed with features that accommodate the unique requirements of working with heavy, durable materials like canvas, Dacron, and other synthetic fabrics commonly used in sail construction.

- Features Look for features that enhance functionality, such as differential feed for handling stretchy fabrics, adjustable presser foot pressure, and ease of threading. Some modern models also come with built-in cutting blades and a free arm for easier access to hard-to-reach areas.

A belt that is too loose will not provide adequate support, while a belt that is too tight can restrict your range of motion and hinder your performance A belt that is too loose will not provide adequate support, while a belt that is too tight can restrict your range of motion and hinder your performance

A belt that is too loose will not provide adequate support, while a belt that is too tight can restrict your range of motion and hinder your performance A belt that is too loose will not provide adequate support, while a belt that is too tight can restrict your range of motion and hinder your performance