centrifugal pump wastewater supplier

Latest articles

2. All have vertical pumps and horizontal pumps and can convey slurry.

centrifugal pump wastewater supplier...

centrifugal pump wastewater supplier 【centrifugal pump wastewater supplier】

Read MoreThe impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

centrifugal pump wastewater supplier...

centrifugal pump wastewater supplier 【centrifugal pump wastewater supplier】

Read MoreSafety

centrifugal pump wastewater supplier...

centrifugal pump wastewater supplier 【centrifugal pump wastewater supplier】

Read MoreSlurry Pump

centrifugal pump wastewater supplier...

centrifugal pump wastewater supplier 【centrifugal pump wastewater supplier】

Read MoreWA Heavy-duty Slurry Pump

centrifugal pump wastewater supplier...

centrifugal pump wastewater supplier 【centrifugal pump wastewater supplier】

Read MoreThe winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

centrifugal pump wastewater supplier...

centrifugal pump wastewater supplier 【centrifugal pump wastewater supplier】

Read MoreDredge Pump

centrifugal pump wastewater supplier...

centrifugal pump wastewater supplier 【centrifugal pump wastewater supplier】

Read MoreWhat is 'slurry'?

centrifugal pump wastewater supplier...

centrifugal pump wastewater supplier 【centrifugal pump wastewater supplier】

Read MoreThere is a better way to pump sewage, overflows and other collected dirty water around the plant.

centrifugal pump wastewater supplier...

centrifugal pump wastewater supplier 【centrifugal pump wastewater supplier】

Read More- Pumping the final product in a process

centrifugal pump wastewater supplier...

centrifugal pump wastewater supplier 【centrifugal pump wastewater supplier】

Read More

Popular articles

- Mud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

- Dredge Pump

- It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

- Slurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

- One of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

- Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

Latest articles

-

Includes a large number of solids or particles.

-

Determine the nature of the material to be pumped

-

To reduce wear, reduce the pump discharge pressure to the lowest possible point.

-

A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

-

Slurry pump seals

-

The terms 'flushing' and 'quench' often seem to be confused or misused when discussing seal support schemes for >slurry pumps. As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

Links

- Conclusion

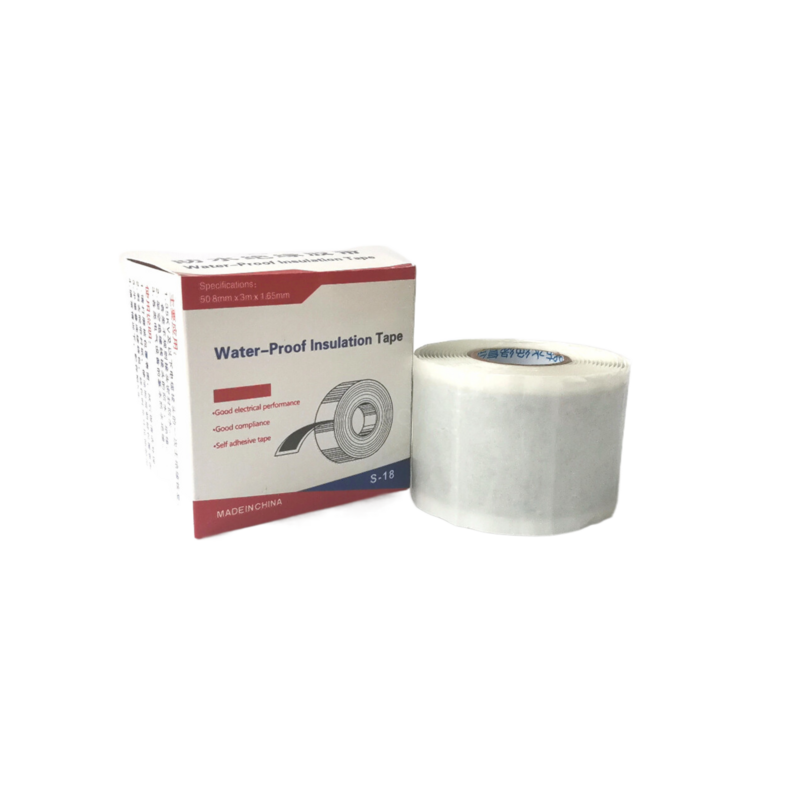

- In the vast array of tools and materials that facilitate modern life, self-adhesive electrical tape is a seemingly modest yet indispensable component. This unassuming strip, with its unique blend of properties, has become an essential utility for both professional contractors and DIY enthusiasts alike.

- Rubber splicing tape, a crucial component in various industries, has become increasingly significant due to its versatility and effectiveness. This specialized tape is primarily composed of rubber or a rubber-like material, offering exceptional elasticity and adhesion. Its primary function is to join or repair materials where flexibility and resilience are paramount.

When using electrical tape, it is important to choose the right size and thickness for the job.

- Flex Tape in white offers all the same reliable qualities as the original black version, but with the added benefit of blending seamlessly with white surfaces. Whether you need to repair a leaky pipe, patch up a hole in your roof, or seal a crack in your boat, Flex Tape in white is the perfect solution for all your repair needs.

Butyl tape comes in single-sided and double-sided varieties, each of which is perfectly suited for specific tasks.

- Butyl rubber exhibits good resistance to UV radiation, which can cause the degradation and weakening of other sealing materials. This ensures that butyl sealant tape will maintain its performance even when exposed to sunlight for extended periods.

Interface

This characteristic makes it ideal for use on materials that expand and contract, such as pipes or rubber seals This characteristic makes it ideal for use on materials that expand and contract, such as pipes or rubber seals

This characteristic makes it ideal for use on materials that expand and contract, such as pipes or rubber seals This characteristic makes it ideal for use on materials that expand and contract, such as pipes or rubber seals

Its robust waterproofing properties make it a go-to choice for both indoor and outdoor applications Its robust waterproofing properties make it a go-to choice for both indoor and outdoor applications

Its robust waterproofing properties make it a go-to choice for both indoor and outdoor applications Its robust waterproofing properties make it a go-to choice for both indoor and outdoor applications