slurry pump casing manufacturer

Latest articles

For certain types of slurry pumping conditions, positive displacement pumps may be a more suitable option than centrifugal pumps.

slurry pump casing manufacturer...

slurry pump casing manufacturer 【slurry pump casing manufacturer】

Read MoreWhy would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

slurry pump casing manufacturer...

slurry pump casing manufacturer 【slurry pump casing manufacturer】

Read MoreSettling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

slurry pump casing manufacturer...

slurry pump casing manufacturer 【slurry pump casing manufacturer】

Read MoreIf the exact in-pump viscosity of the product is unknown, CSI can help

slurry pump casing manufacturer...

slurry pump casing manufacturer 【slurry pump casing manufacturer】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

slurry pump casing manufacturer...

slurry pump casing manufacturer 【slurry pump casing manufacturer】

Read MoreWhen pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

slurry pump casing manufacturer...

slurry pump casing manufacturer 【slurry pump casing manufacturer】

Read MoreSlurry Pump

slurry pump casing manufacturer...

slurry pump casing manufacturer 【slurry pump casing manufacturer】

Read MoreSlurry pumps are usually larger than standard pumps, have more horsepower and use stronger bearings and shafts. The most common >type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids pass through a standard centrifugal pump.

slurry pump casing manufacturer...

slurry pump casing manufacturer 【slurry pump casing manufacturer】

Read MoreA quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

slurry pump casing manufacturer...

slurry pump casing manufacturer 【slurry pump casing manufacturer】

Read MoreHydrostatic head - i.e. the height to which the slurry must be lifted in the piping system.

slurry pump casing manufacturer...

slurry pump casing manufacturer 【slurry pump casing manufacturer】

Read More

Popular articles

- WL Series Light-duty pumps are cantilevered, horizontal centrifugal slurry pumps. They are suitable for delivering low density slurries for metallurgical, mining, coal and building material departments. The shaft seal adopts both gland seal and centrifugal seal.

- Slurry Pump

- Slurry Pump

- how-does-a-dredge-pump-work

- All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

- These conditions include

Latest articles

-

Mill sump

-

Larger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

-

WZ series slurry pumps are new type wear resistant & corrosion resistant slurry pump for the complexity and specificity of coal, power plant, metallurgy, chemical, building materials and other industries.

-

testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

-

All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

-

Aier Machinery's team of consultants are on hand to provide you with a solution to your needs. Whether you are planning to purchase a slurry pump or need spare parts for an existing pump, we will help you determine your needs and provide advice on fine-tuning your equipment to your specific application.

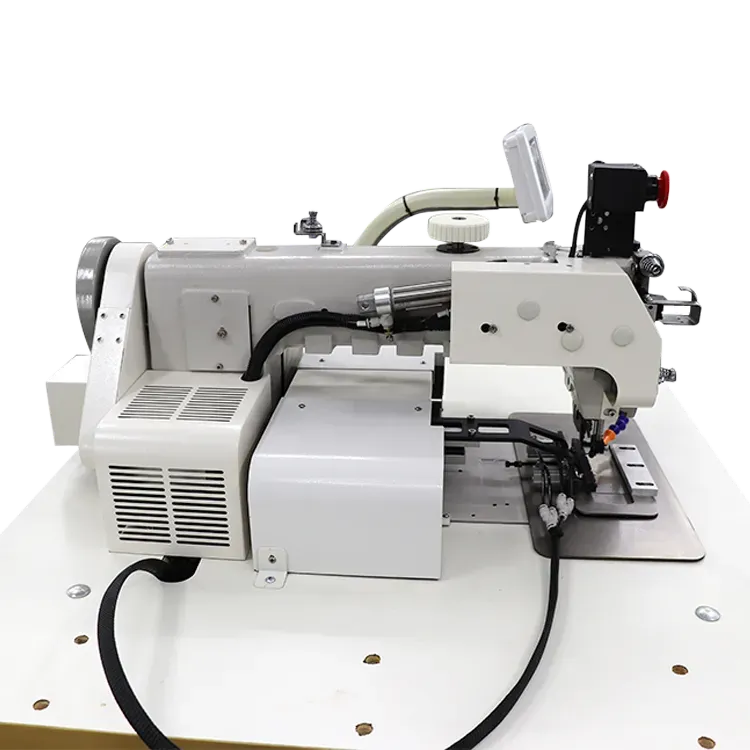

2. Walking Foot Mechanism A walking foot, or even a roller foot, is essential for sewing leather, as it helps to grip the material evenly, preventing slipping during operation. This feature is particularly important when sewing multiple layers of leather.

Advantages of Using a Double Stitch Machine

Upholstery sewing tables are indispensable pieces of furniture for anyone engaged in the craft of upholstery. Whether you are a professional upholsterer or a DIY enthusiast looking to revamp your furniture, having the right sewing table can significantly enhance your sewing experience. In this article, we’ll explore the features, benefits, and tips for choosing the perfect upholstery sewing table.

A 3-needle chain stitch machine is a type of sewing machine that utilizes three needles to create a chain stitch, which is characterized by a series of interlocking loops. This machine employs multiple threads, often using a combination of two or three needle threads and a looper thread, to form a robust seam that is both flexible and strong. The chain stitch construction allows for a unique stretch, making it ideal for textiles that require elasticity, such as sportswear and activewear.

5. Durability A beginner's sewing machine should be sturdy enough to withstand repetitive use. A metal frame is preferable over plastic to ensure long-lasting performance.