submersible water pump 6 inch factories

Latest articles

Dredge Pump Features

submersible water pump 6 inch factories...

submersible water pump 6 inch factories 【submersible water pump 6 inch factories】

Read MoreTo reduce wear, reduce the pump discharge pressure to the lowest possible point.

submersible water pump 6 inch factories...

submersible water pump 6 inch factories 【submersible water pump 6 inch factories】

Read MorePumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

submersible water pump 6 inch factories...

submersible water pump 6 inch factories 【submersible water pump 6 inch factories】

Read MoreMonitoring

submersible water pump 6 inch factories...

submersible water pump 6 inch factories 【submersible water pump 6 inch factories】

Read MoreOne of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

submersible water pump 6 inch factories...

submersible water pump 6 inch factories 【submersible water pump 6 inch factories】

Read MoreFor pumping abrasive slurries, these types of pumps can also be made from specialised high-wear alloys. Hardened stainless steel is also a common choice for abrasive slurries.

submersible water pump 6 inch factories...

submersible water pump 6 inch factories 【submersible water pump 6 inch factories】

Read MoreSlurry Pump Impeller Size

submersible water pump 6 inch factories...

submersible water pump 6 inch factories 【submersible water pump 6 inch factories】

Read More- Low noise level - Operating underwater results in low noise or even silent operation.

submersible water pump 6 inch factories...

submersible water pump 6 inch factories 【submersible water pump 6 inch factories】

Read MoreAlthough the focus of slurry pumps is often on the size and percentage of solids to be pumped, in many applications corrosion resistance is also an important factor in material selection. In such cases, the material chosen must provide adequate resistance to erosion and corrosion.

submersible water pump 6 inch factories...

submersible water pump 6 inch factories 【submersible water pump 6 inch factories】

Read More- Easy installation - Submersible pumps are relatively easy to install since the motor and worm gear are a single unit.

submersible water pump 6 inch factories...

submersible water pump 6 inch factories 【submersible water pump 6 inch factories】

Read More

Popular articles

- The concept of the , slurry pump, and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

- The company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

- >TL FGD Pump

- Slurry Pump

- Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

- Desire for higher efficiency than centrifugal pumps

Latest articles

-

Centrifugal slurry pumps capable of providing high capacity with a limited head are mainly used for pumping slurry through pipes with a concentration of less than 70% by weight of solids. Centrifugal slurry pumps can be vertical, horizontal or submersible.

-

WZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

-

Determine the perfect combination of slow pumping (to reduce wear) and fast pumping to prevent solids from settling and clogging.

-

Slurry Pump

-

To find out more about Aier slurry Pumps, please >contact us.

-

Slurry pump vs mud pump

Links

Whether you are working on home decor, crafting accessories, or sewing clothes, the automatic backstitch feature proves to be universally beneficial. Given its application across diverse projects, it allows sewists to switch between tasks seamlessly without the constant need to adjust techniques. This versatility is especially valuable for those who take on different kinds of projects and need the reliability of a solid stitch to ensure quality, regardless of fabric type or design complexity.

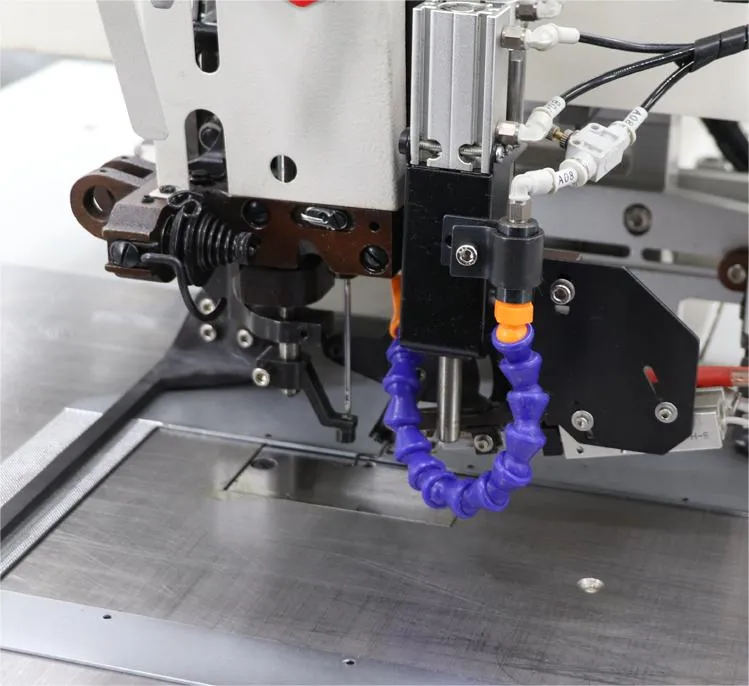

- In addition to their speed and strength, hi-speed lockstitch machines are also known for their precision. These machines are equipped with advanced tension control systems that help to ensure even stitching and prevent thread breakage. This level of precision is crucial for creating high-quality garments that look professional and are built to last.

1. Increased Efficiency Automation reduces the time it takes to seal bags, allowing for faster production rates and minimizing labor costs. In high-demand settings, this can be a game changer for meeting tight deadlines.

plastic bag closer machine

Importance of Specialized Machinery

Finding the Right Machine for You

One of the key features of a woven sack sewing machine is its speed and efficiency. These machines are designed to work quickly and accurately, allowing for high volume production of woven sacks. This is essential for industries that require large quantities of sacks to package their goods for distribution.

woven sack sewing machine

A bag seaming machine is a specialized piece of equipment used to join the edges of bags, usually made from materials like plastic, woven polypropylene, paper, or cloth. These machines employ different seaming techniques, including heat sealing, ultrasonic sealing, and stitching, to create strong and durable seals that can withstand various handling and transportation conditions.

The machine is simple enough, and you’re buying it for the strength and durability, not the bells and whistles. But it will auto-wind your bobbin (the lower spool of thread beneath the needle) and includes a hundred or so stitching patterns, if that’s your thing. There’s a dial selector for the type of stitch, and then a dial to adjust the length of it. You can tackle button holes, add zippers, tailor pants and shirts, and all of that.

1. Pre-wash Your Fabric If your canvas isn’t pre-treated, wash and dry it before starting your project. This pre-wash ensures that any shrinkage occurs before you cut and sew.

Presser feet act as the main point of contact between the machine and the fabric. For light fabrics, specialized feet can make a world of difference. A walking foot, for instance, ensures even fabric feed from both top and bottom, reducing puckering. A Teflon or roller foot can prevent fabrics like silk or satin from getting stuck. A narrow straight stitch foot can offer more precision when sewing straight seams on delicate fabrics.

The Versatility and Strength of Heavy Duty Hand Stitching Machines

5. Built-in Stitch Options A variety of built-in stitch options can enhance creativity in your projects. While straight stitching is crucial, having zigzag and decorative stitches can open up more possibilities for unique designs.

%20(200%20%C3%97%20200%20px)%20(3).webp)

In addition, the ability to adjust the tension of both threads allows for customization, ensuring the perfect stitch for every fabric and design In addition, the ability to adjust the tension of both threads allows for customization, ensuring the perfect stitch for every fabric and design

In addition, the ability to adjust the tension of both threads allows for customization, ensuring the perfect stitch for every fabric and design In addition, the ability to adjust the tension of both threads allows for customization, ensuring the perfect stitch for every fabric and design