high quality centrifugal slurry pump spare parts

Latest articles

BCT Ceramic Slurry Pumps

high quality centrifugal slurry pump spare parts...

high quality centrifugal slurry pump spare parts 【high quality centrifugal slurry pump spare parts】

Read Morereduce the discharge pressure of the pump to the lowest possible point, and.

high quality centrifugal slurry pump spare parts...

high quality centrifugal slurry pump spare parts 【high quality centrifugal slurry pump spare parts】

Read MoreSlurry Pump VS Mud Pump

high quality centrifugal slurry pump spare parts...

high quality centrifugal slurry pump spare parts 【high quality centrifugal slurry pump spare parts】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

high quality centrifugal slurry pump spare parts...

high quality centrifugal slurry pump spare parts 【high quality centrifugal slurry pump spare parts】

Read MoreDesire for higher efficiency than centrifugal pumps

high quality centrifugal slurry pump spare parts...

high quality centrifugal slurry pump spare parts 【high quality centrifugal slurry pump spare parts】

Read MoreConsider the pump components

high quality centrifugal slurry pump spare parts...

high quality centrifugal slurry pump spare parts 【high quality centrifugal slurry pump spare parts】

Read MoreIs the discharge configuration suitable for abrasive slurries?

high quality centrifugal slurry pump spare parts...

high quality centrifugal slurry pump spare parts 【high quality centrifugal slurry pump spare parts】

Read MoreOne problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

high quality centrifugal slurry pump spare parts...

high quality centrifugal slurry pump spare parts 【high quality centrifugal slurry pump spare parts】

Read MoreA typical pump solution for this application is to install a hard metal >slurry pump to withstand these types of conditions. Hard metal pumps need to be able to withstand the most severe abrasive slurry service and they also need to be designed to be extremely easy to maintain and safe.

high quality centrifugal slurry pump spare parts...

high quality centrifugal slurry pump spare parts 【high quality centrifugal slurry pump spare parts】

Read MoreThe type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

high quality centrifugal slurry pump spare parts...

high quality centrifugal slurry pump spare parts 【high quality centrifugal slurry pump spare parts】

Read More

Popular articles

- Rubber lined pumps offer many advantages

- Submersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

- Slurry Pump Impeller Size

- The impeller is considered the heart of the dredge pump and is similar to a fan that expels air and creates centrifugal suction. At the suction pipe, this vacuum absorbs the slurry and transports the material through the discharge line.

- Follow proper piping principles to ensure consistent and uniform delivery of mud to the pump.

- Any type of impeller can be used in slurry applications, but closed slurry pump impellers are more common because they are high efficient and abrasion Resistance,. Open slurry pump impellers are usually used well for high concentration solids as they are less likely to clog. For example, the small fibers in paper stock which, in high densities, may have a tendency to clog the impeller. Pumping slurry can be difficult.

Latest articles

-

The Difference Between Flushing And Quenching in Slurry Pump Seals

-

What is Heavy Duty Slurry Pump?

-

Better safety

-

Submersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

-

When the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

-

Slurry Pump

Links

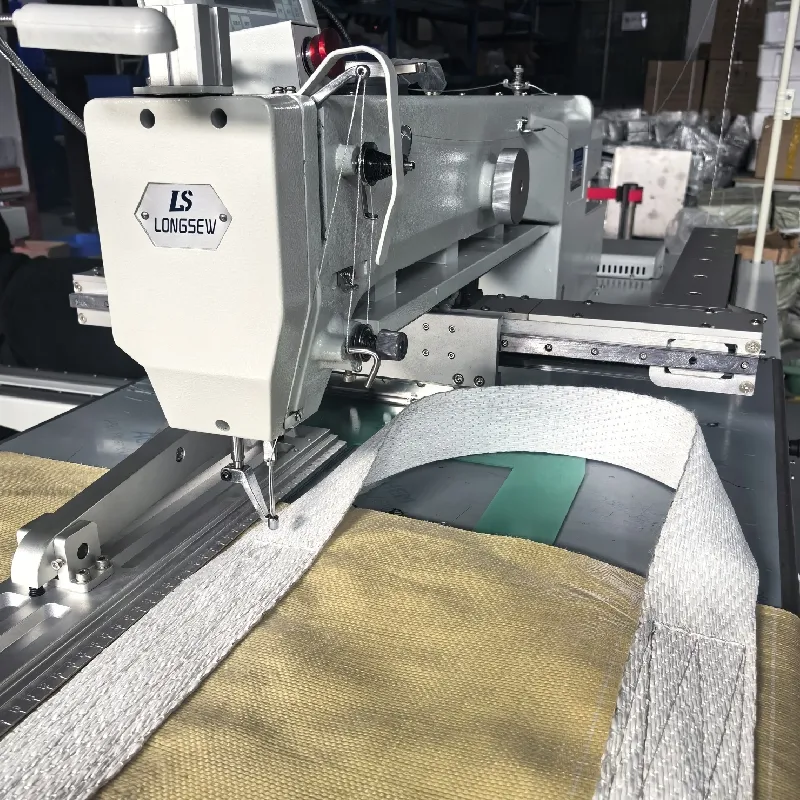

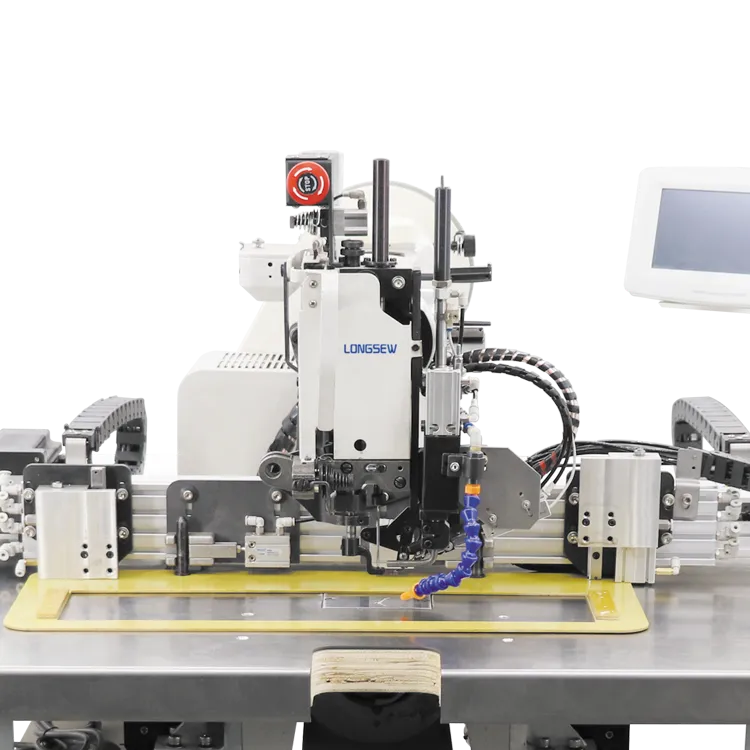

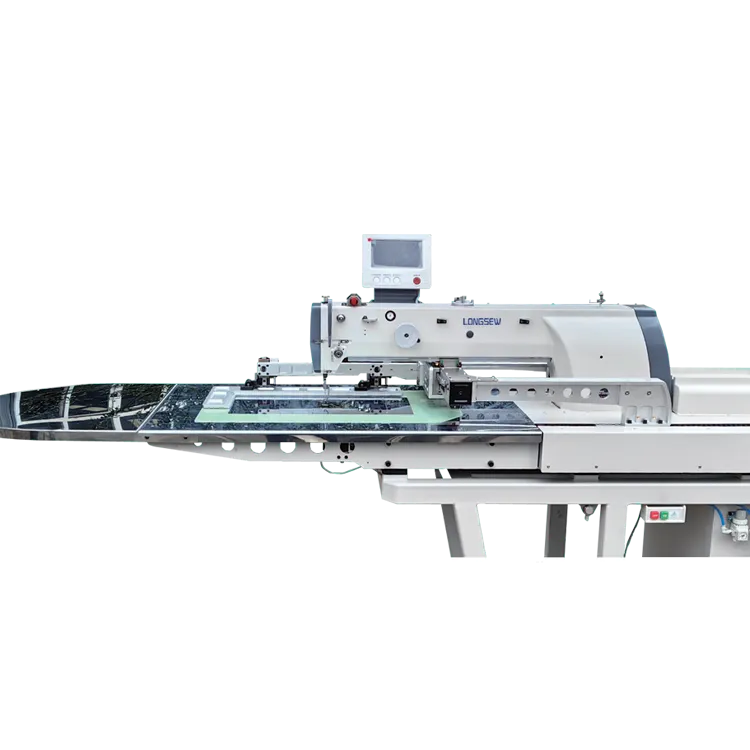

Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

The single needle lock stitch is achieved using a sewing machine equipped with a needle and a bobbin. The process begins when the needle pierces the fabric, carrying the upper thread down into the fabric layers. As the needle goes down, the bobbin, which is located underneath the fabric, rotates. The upper thread wraps around the bobbin thread, forming a stitch. When the needle pulls back up, the thread tightens, securing the stitch in place.

2. Enhanced Fabric Handling The design of the zigzag presser foot allows for better control over the fabric as it moves through the machine. This is particularly beneficial when sewing with stretchy or slippery materials.

Before you purchase a sewing machine, you have to consider what you will be using it for and how often you use it. Usually, heavy duty sewing machines are used in industries because of their dependability and durability. These machines are equipped to handle tough tasks. The type of machine is quite excellent as far as dealing with heavy fabrics such as animal skin, denim, and leather. You will find it great for making blinds, buttonholes, quilts, and upholstery. These are some factors to consider before buying.

Before you purchase a sewing machine, you have to consider what you will be using it for and how often you use it. Usually, heavy duty sewing machines are used in industries because of their dependability and durability. These machines are equipped to handle tough tasks. The type of machine is quite excellent as far as dealing with heavy fabrics such as animal skin, denim, and leather. You will find it great for making blinds, buttonholes, quilts, and upholstery. These are some factors to consider before buying. They are made with high-quality materials and components that ensure long-lasting performance, even under heavy workloads They are made with high-quality materials and components that ensure long-lasting performance, even under heavy workloads

They are made with high-quality materials and components that ensure long-lasting performance, even under heavy workloads They are made with high-quality materials and components that ensure long-lasting performance, even under heavy workloads