china wastewater centrifugal pump factory

Latest articles

Keep in mind that slurry pumps are designed to adapt to specific pumping conditions. Pumps used in the cement industry handle most fine particles at low pressures, so the casing can be of lightweight construction. In rock pumping, the casing and impeller must be able to resist slamming, so they must be built thick and strong.

china wastewater centrifugal pump factory...

china wastewater centrifugal pump factory 【china wastewater centrifugal pump factory】

Read MoreThe discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

china wastewater centrifugal pump factory...

china wastewater centrifugal pump factory 【china wastewater centrifugal pump factory】

Read MoreThe slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

china wastewater centrifugal pump factory...

china wastewater centrifugal pump factory 【china wastewater centrifugal pump factory】

Read MoreMill sump

china wastewater centrifugal pump factory...

china wastewater centrifugal pump factory 【china wastewater centrifugal pump factory】

Read MoreParticle size, shape and hardness (impact on wear and corrosion potential of pump components)

china wastewater centrifugal pump factory...

china wastewater centrifugal pump factory 【china wastewater centrifugal pump factory】

Read More- Keeping clean catch basins clean from solids

china wastewater centrifugal pump factory...

china wastewater centrifugal pump factory 【china wastewater centrifugal pump factory】

Read MoreSlurry pump design

china wastewater centrifugal pump factory...

china wastewater centrifugal pump factory 【china wastewater centrifugal pump factory】

Read MoreApplications

china wastewater centrifugal pump factory...

china wastewater centrifugal pump factory 【china wastewater centrifugal pump factory】

Read MoreDefinition of dredge and slurry pumps

china wastewater centrifugal pump factory...

china wastewater centrifugal pump factory 【china wastewater centrifugal pump factory】

Read MoreChoosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

china wastewater centrifugal pump factory...

china wastewater centrifugal pump factory 【china wastewater centrifugal pump factory】

Read More

Popular articles

- Pumping slurry can cause excessive wear and tear on the pump and its components as the mud can clog the suction and discharge lines.

- Slurry Pump

- Types of damage to slurry pumps

- >Slurry Pump

- There is a science behind the design of a >slurry pump, based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

- All products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

Latest articles

-

Working principle

-

The company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

-

Carbon transfer

-

Magnetite mixing

-

Find the best position that allows the pump to run as slowly as possible (to reduce wear) but fast enough to prevent solids from settling and clogging the piping.

-

The concept of the >slurry pump and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

Links

- The manufacturing process typically begins with the selection of raw aluminium, which is then melted down in a furnace. Once molten, the aluminium is forced through dies under high pressure, creating the desired shape and size of the profile. This process, known as extrusion, allows manufacturers to create a wide range of designs, from simple to complex, to meet diverse architectural requirements.

Cutting

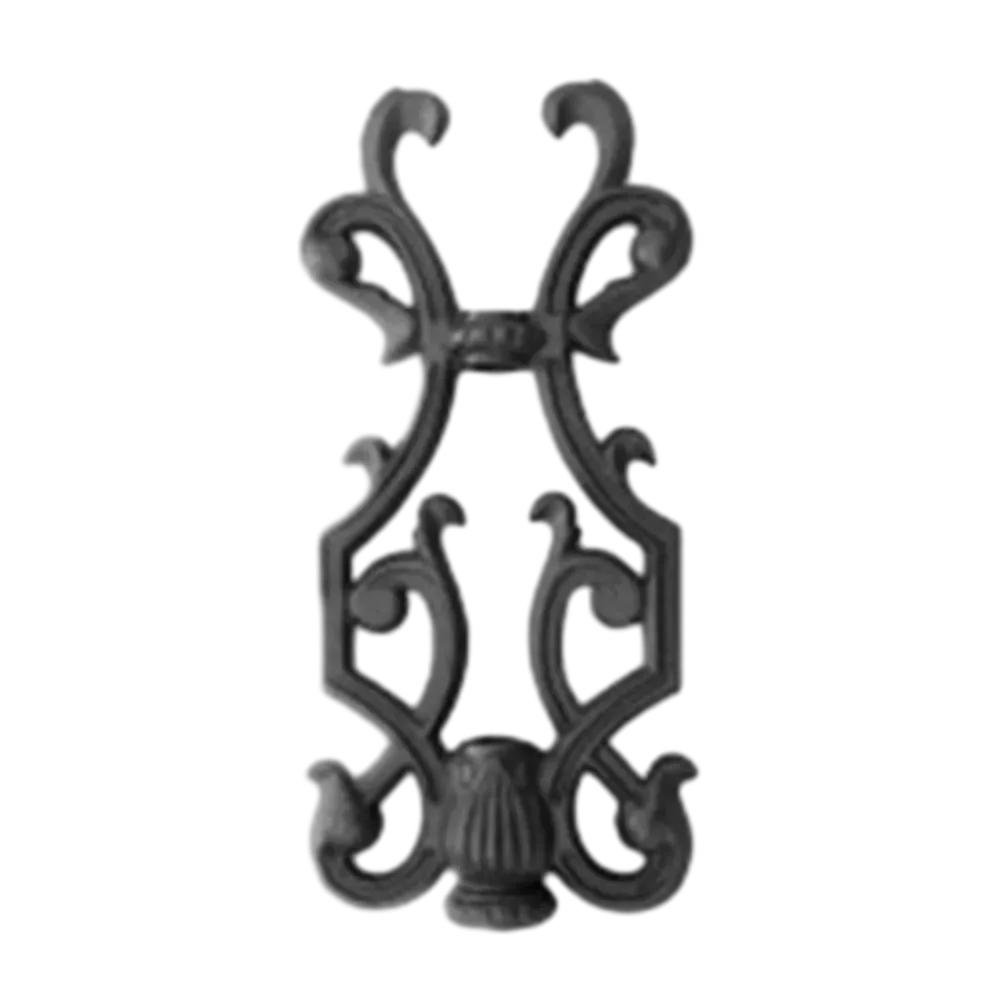

Many ornamental cast iron manufacturers also offer customization services, allowing customers to create unique pieces that suit their specific needs and preferences. Whether it's a custom gate for a private residence or a decorative railing for a commercial building, manufacturers can work closely with their clients to bring their vision to life.

The charm of ornamental wrought iron lies in its historical roots. Dating back to ancient times, wrought iron was primarily utilized for practical purposes, such as constructing tools and weapons. However, its decorative potential began to be recognized during the Middle Ages, particularly in Europe. Skilled blacksmiths began to experiment with the malleability of the material, resulting in intricate patterns and embellishments that transformed simple structures into works of art.

Advanced Surface Treatment of Aluminum Profiles For Window and Door System

Another appealing feature of these lock boxes is their portability. Many are designed to be lightweight and easy to transport, making them perfect for individuals who need security on the go. They offer an accessible storage solution without sacrificing security. Whether you need to move items from one job site to another or transport personal belongings during travel, a metal storage lock box can be an efficient and secure option.

Check the available prices for these panels. Galvanized and powder coated. Fully Welded.

Packing:

With this in mind, manufacturers have ingeniously come up with numerous ways to create aluminum profiles. Their uses range from simple door kick plates and window frames to far more complex, larger-scale applications such as shipping containers and piping channels. Continue reading to learn more.

Methods of Disposal

In conclusion, slimline aluminium profiles represent a perfect amalgamation of modern aesthetics and functional strength. Their versatility, durability, and attractive appearance make them an ideal choice for a wide range of applications across different sectors. As the demand for innovative, sustainable design continues to grow, the slimline aluminium profile is poised to play an even more central role in shaping the built environment of the future. Whether for homes, offices, or commercial spaces, these profiles provide an elegant solution that meets the needs of today’s dynamic design landscape.

Knowledge of installation:

This flexibility has given rise to creative uses of space, such as concealed pantries, built-in wardrobes, and partition walls that do not impede on the sense of openness in a home This flexibility has given rise to creative uses of space, such as concealed pantries, built-in wardrobes, and partition walls that do not impede on the sense of openness in a home

This flexibility has given rise to creative uses of space, such as concealed pantries, built-in wardrobes, and partition walls that do not impede on the sense of openness in a home This flexibility has given rise to creative uses of space, such as concealed pantries, built-in wardrobes, and partition walls that do not impede on the sense of openness in a home sliding door wheel.

sliding door wheel.Brief Introduction of Aluminum Profiles For Window and Door System

We take it up a notch by offering custom-made wrought iron fences, even though our main focus is on installations. That means crafting unique designs for each project, reflecting the distinctiveness of your space.

This FAQs guide presents in-depth information regarding various aspects of these aluminum products.

One of the key advantages of cast iron ornaments is their durability. Made from a material known for its strength and resilience, these decorations can withstand the elements and remain in good condition for many years. This makes them an excellent choice for outdoor use, where they can add beauty to a garden or patio without the risk of damage from rain, wind, or sun exposure.