china atlantic slurry pump

Latest articles

Heavy-Duty Slurry Pump

china atlantic slurry pump...

china atlantic slurry pump 【china atlantic slurry pump】

Read MoreSlurry Pump

china atlantic slurry pump...

china atlantic slurry pump 【china atlantic slurry pump】

Read MoreIf centrifugal, are the impellers of the right design and material?

china atlantic slurry pump...

china atlantic slurry pump 【china atlantic slurry pump】

Read MoreIn dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

china atlantic slurry pump...

china atlantic slurry pump 【china atlantic slurry pump】

Read More>Dredge Pump

china atlantic slurry pump...

china atlantic slurry pump 【china atlantic slurry pump】

Read MoreWY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

china atlantic slurry pump...

china atlantic slurry pump 【china atlantic slurry pump】

Read MorePumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

china atlantic slurry pump...

china atlantic slurry pump 【china atlantic slurry pump】

Read MoreWhat is the best seal arrangement for the application?

china atlantic slurry pump...

china atlantic slurry pump 【china atlantic slurry pump】

Read MoreThere are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

china atlantic slurry pump...

china atlantic slurry pump 【china atlantic slurry pump】

Read MoreWhen the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

china atlantic slurry pump...

china atlantic slurry pump 【china atlantic slurry pump】

Read More

Popular articles

- 1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

- It is often used if a short period of dry running is expected. Fluid is introduced into the area between the back of the seal face and the tight-fitting outlet on the drive side of the slurry pump.

- Types of slurry pumps

- Slurry Pump Impeller Type

- Slurry Pump

- Submersible slurry pump pumps offer many advantages over dry and semi-dry (cantilever) mounted pumps.

Latest articles

-

What is a dredging pump?

-

There are many factors that should be considered when investing in a slurry pump. For example, it is important to consider the type of slurry, as the solids content of slurries can vary from 1% to 70%. It is also important to consider the level of wear and corrosion of the material being pumped; coal and some ores can corrode parts and damage your equipment fairly quickly, often beyond repair. This wear and tear can add significantly to operating costs, and you may eventually need to purchase new equipment to continue working.

-

If you want to get more information about the best slurry pump, welcome to >contact us today or request a quote.

-

The slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

-

>Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

-

Abrasive.

Links

- Cast iron griddles are made by pouring molten iron into a mold and then allowing it to cool and solidify. This process gives the griddle its characteristic rough, porous surface, which helps food cook evenly and retain moisture. The griddle can then be seasoned with oil or fat, which creates a non-stick coating that only gets better with use.

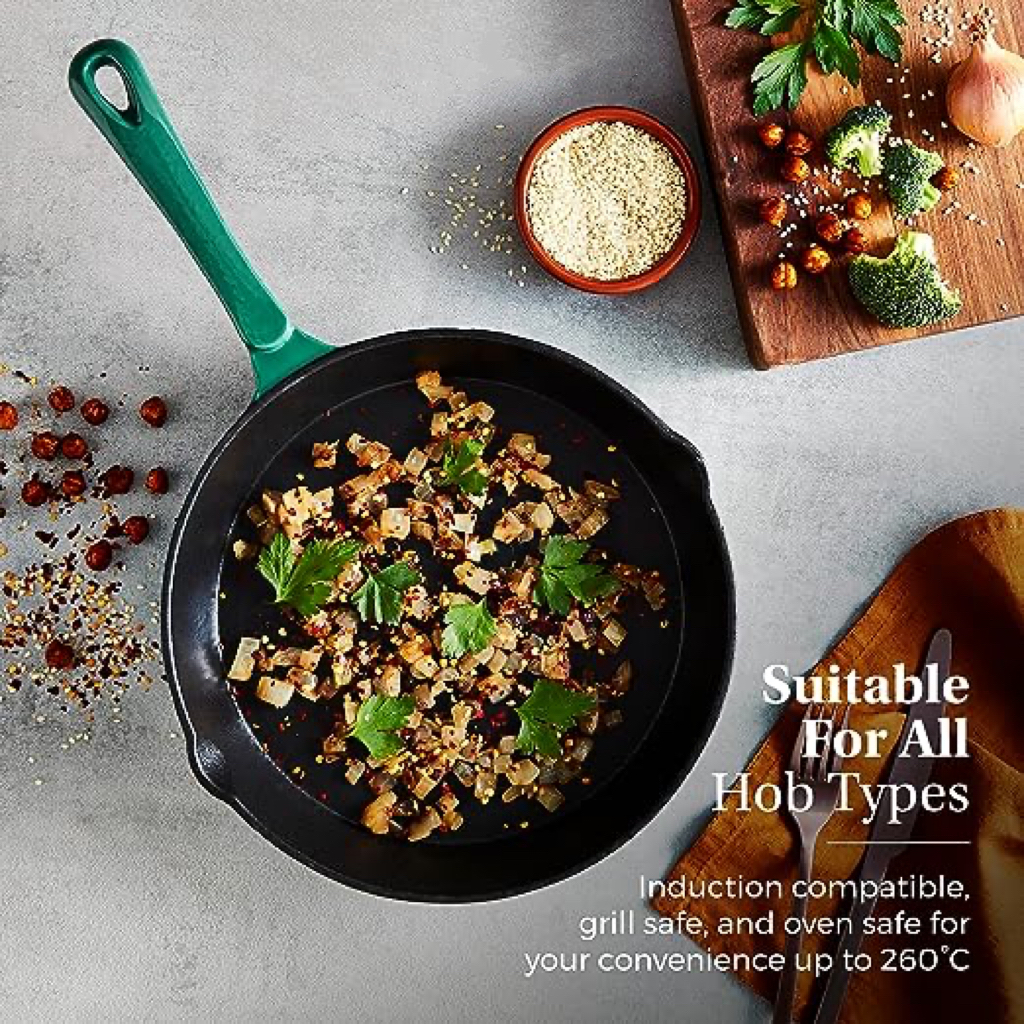

Cast griddle plates are a versatile and essential addition to any kitchen. Whether you want to grill a steak, roast vegetables, or cook delicious pancakes, a Cast griddle plate is the perfect tool. With their even heat distribution and durable construction, it's no wonder these Cast griddle pans are a favorite among home cooks and professional chefs alike.

- In conclusion, the price of a cast iron grill pan is influenced by several factors, including quality, design, brand reputation, size, and market conditions. While a higher price doesn't always guarantee the best product, investing in a well-made, durable grill pan can be a worthwhile expense considering its long-term benefits. Always weigh your options, read reviews, and consider your cooking needs before making a purchase. Remember, a good cast iron grill pan is not just a kitchen tool; it's an investment in timeless culinary enjoyment.

The ideal cookware size is a personal choice and a lifestyle choice. Smaller skillets and sauté pans are great for one- or two-person meals or quick bites (ex., breakfast scrambles or side dishes), while larger sizes are able to cook family-size portions or complete one-pan meals.

Dutch ovens, on the other hand, are known for their versatility. Dutch ovens can be used for everything from soups and stews to toast and roasts.

Whether you're looking for classic white enamel cookware or colorful enamel pots to add a pop of personality to your kitchen, enamel cookware cooking pots are a versatile and practical choice. With their durability, ease of maintenance, and variety of colors, the enamelware cooking pot is sure to be a much-loved addition to your kitchen for years to come.

How to clean: scrub with a plastic brush, which won't scratch. Before cooking, rub 1/2 teaspoon oil inside to safeguard the nonstick surface.

Color Enamel Cookware Set

Related: The Best Pots & Pans and What To Do With Them

Traditional round skillets are versatile, while square or rectangular ones offer more surface area, ideal for pancakes or fajitas Traditional round skillets are versatile, while square or rectangular ones offer more surface area, ideal for pancakes or fajitas

Traditional round skillets are versatile, while square or rectangular ones offer more surface area, ideal for pancakes or fajitas Traditional round skillets are versatile, while square or rectangular ones offer more surface area, ideal for pancakes or fajitas iron skillets for sale. Some skillets come with a helper handle for easier lifting.

iron skillets for sale. Some skillets come with a helper handle for easier lifting.Material

Whether you're cooking up a hearty breakfast of pancakes and bacon, searing a perfect steak for dinner, or grilling vegetables for a healthier meal option, the cast iron grill griddle pan can handle it all Whether you're cooking up a hearty breakfast of pancakes and bacon, searing a perfect steak for dinner, or grilling vegetables for a healthier meal option, the cast iron grill griddle pan can handle it all

Whether you're cooking up a hearty breakfast of pancakes and bacon, searing a perfect steak for dinner, or grilling vegetables for a healthier meal option, the cast iron grill griddle pan can handle it all Whether you're cooking up a hearty breakfast of pancakes and bacon, searing a perfect steak for dinner, or grilling vegetables for a healthier meal option, the cast iron grill griddle pan can handle it all cast iron grill griddle pan.

cast iron grill griddle pan.When to Cook With a Skillet

Versatile Culinary Tools:

Unlike non-stick pans, cast iron pans do not require the use of harsh chemicals or abrasive cleaners Unlike non-stick pans, cast iron pans do not require the use of harsh chemicals or abrasive cleaners

Unlike non-stick pans, cast iron pans do not require the use of harsh chemicals or abrasive cleaners Unlike non-stick pans, cast iron pans do not require the use of harsh chemicals or abrasive cleaners cast iron fish fry pan. Simply rinse the pan with warm water and a mild soap, then dry it thoroughly with a towel. Over time, your cast iron pan will develop a natural non-stick coating, making it even easier to clean.

cast iron fish fry pan. Simply rinse the pan with warm water and a mild soap, then dry it thoroughly with a towel. Over time, your cast iron pan will develop a natural non-stick coating, making it even easier to clean. cast iron vegetable grill pan. Proper care involves regular seasoning with oil to prevent rust and maintain its non-stick properties. Over time, the seasoning builds up, creating a patina that is both beautiful and functional.

cast iron vegetable grill pan. Proper care involves regular seasoning with oil to prevent rust and maintain its non-stick properties. Over time, the seasoning builds up, creating a patina that is both beautiful and functional.