slurry pump parts supplier

Latest articles

How to Succeed in Slurry Pumping?

slurry pump parts supplier...

slurry pump parts supplier 【slurry pump parts supplier】

Read MoreTypes of damage to slurry pumps

slurry pump parts supplier...

slurry pump parts supplier 【slurry pump parts supplier】

Read More>Slurry Pump

slurry pump parts supplier...

slurry pump parts supplier 【slurry pump parts supplier】

Read MoreSlurry Pump

slurry pump parts supplier...

slurry pump parts supplier 【slurry pump parts supplier】

Read MoreThe concept of the , slurry pump, and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

slurry pump parts supplier...

slurry pump parts supplier 【slurry pump parts supplier】

Read MoreWhat is the optimum seal arrangement for the application?

slurry pump parts supplier...

slurry pump parts supplier 【slurry pump parts supplier】

Read MoreWA Heavy-duty Slurry Pump

slurry pump parts supplier...

slurry pump parts supplier 【slurry pump parts supplier】

Read MoreTL FGD Pump

slurry pump parts supplier...

slurry pump parts supplier 【slurry pump parts supplier】

Read MoreThe Difference Between Flushing And Quenching in Slurry Pump Seals

slurry pump parts supplier...

slurry pump parts supplier 【slurry pump parts supplier】

Read MoreWhen the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

slurry pump parts supplier...

slurry pump parts supplier 【slurry pump parts supplier】

Read More

Popular articles

- What are the materials used to construct the pump?

- On the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

- The slurry weight or consistency determines the type, design and capacity of the slurry pump required. If you have any questions about the best pump for your application, welcome to >contact us today or request a quote.

- Slurry Pump

- If you have experience pumping slurry, you know it is not an easy task. Slurries are heavy and difficult to pump. They can cause excessive wear on the pump and its components, and if they don't move fast enough, they can clog the suction and discharge lines. Most importantly, it can be a challenge to keep a slurry pump in use for a reasonable period of time. However, there are steps you can take to extend the life of your slurry pump and reduce the challenges of pumping slurry.

- The terms flushing and quench, often seem to be confused or misused when discussing seal support schemes for , slurry pumps, . As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

Latest articles

-

I hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

-

Auxiliary equipment

-

>Slurry Pump vs Mud Pump

-

There is a science behind the design of a >slurry pump, based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

-

Customised solutions

-

As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

Links

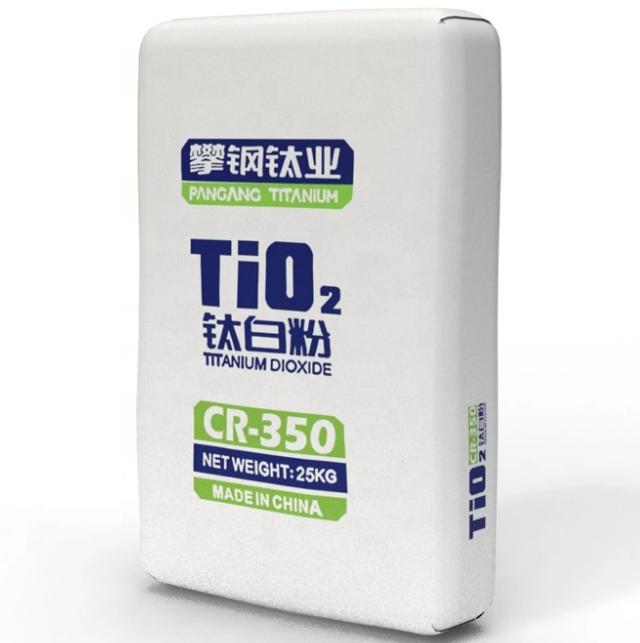

To overcome this challenge, manufacturers use advanced technology and processes to monitor and control the buff percentage of their products. This may involve the use of sophisticated equipment to measure the coating thickness of titanium dioxide particles, as well as automated systems to adjust the level of coating as needed. By carefully controlling the buff percentage, manufacturers can ensure that their products meet the specifications of their customers and maintain a high level of quality and performance.

Package:

25KG/50KG Woven bag with inner, or 1000kg big woven plastic bag.

Company Information

Loman Chemical Group (include Shanghai Loman Chemical Co Ltd; Wuhu Loman Chemical Co Ltd and Wuhu Loman Titanium Industial Co Ltd.)is one of the main titanium dioxide manufacturers in china, producing various high quality Anatase and Rutile titanium dioxide. Loman brand products, has being widely used in paper, paint, plastic, ink, coating, rubber, cosmetic, food, fiber, etc.

In order to meet different requirements of various customers, we actively expand producing other pigments, include Lithopone, Barium sulfate and Silica. Annual production volume of anatase and rutile grade titanium dioxide have reached 100,000 tons, lithopone 30.000 tons, barium sulfate 50.000 tons and precipitated silica 8.000 tons. The Loman brand is one of the famous brands in China, having great popularity both at home and abroad. Our products have been widely used in European, North America and Southeast Asia.

Our advantages:

1)With the most professional manufacturers,High quality and high safety product

2)Professional consulting services are availabe for you at antyime

3)Have a favorable price ,reliable quality

4)Complete products meet your purchasing needFAQ – EFSA 2021 safety assessment of titanium dioxide (E171)

- In conclusion, the realm of anatase TiO2 pigment manufacturing is dynamic and continuously evolving. Manufacturers play a pivotal role in supplying a product that touches numerous aspects of daily life, from the lotions we apply to the paints used in our homes. As they navigate challenges related to cost, environment, and regulation, they continue to innovate, ensuring that anatase TiO2 remains a cornerstone of modern industry and consumer products.

Topical Exposure

- In the cosmetics industry, titanium dioxide is used as a sunscreen agent to protect skin from harmful UV rays. It is also used in makeup products such as foundations and powders to provide a natural-looking coverage and a radiant finish. The micronized form of titanium dioxide is particularly effective at absorbing UV light, making it a popular choice among consumers who are concerned about sun protection.