china oem slurry pump engineering factory

Latest articles

sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreHow to Succeed in Slurry Pumping?

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreCapacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreHow to Choose a Dredging Pump or Slurry Pump

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreHow much solids damage can the customer tolerate?

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MorePacking the box seal

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreCustomised pumps

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreDredge Pump Features

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreSubmersible slurry pump pumps offer many advantages over dry and semi-dry (cantilever) mounted pumps.

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MorePumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal target=_blank title=Slurry Pump>slurry pump. Let's talk about how slurry pumps differ from standard pumps and how to narrow your choices.

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read More

Popular articles

- Quenching is defined as the introduction of a neutral fluid (usually water or steam) into the atmospheric side of the seal to prevent the formation of solids that may interfere with movement or be used for other purposes.

- Auxiliary equipment

- Metal and/or rubber pump bushings are used to combat the erosion of solid particles found in the slurry. Metal slurry pump housings are usually made of carbide to resist erosion caused by increased pressure and circulation. Sometimes wear-resistant steel is used on the pump casing so that the pump can be welded if repairs are needed.

- Slurry Pump

- If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

- >Dredge Pump

Latest articles

-

Aier is pumping experts and offer some useful tips to maintain your >slurry pump.

-

Settling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

-

Typical Applications of slurry pump

-

As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

-

There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

-

The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

Links

Conclusion

In conclusion, the significance of China steel wire rope in the global market cannot be overstated. With its combination of affordability, quality, and versatility, China's steel wire ropes have become integral components for a variety of industries. As the world continues to evolve and demand for robust and reliable materials grows, it is likely that China's influence in the steel wire rope market will expand even further. The ongoing commitment to innovation, efficiency, and quality assurance will help ensure that Chinese steel wire ropes remain a vital resource for industries worldwide.

Electro galvanized barbed wire from China presents an effective solution for those in need of reliable fencing options. With its corrosion-resistant properties and versatility in applications, it is an essential material across various sectors. When sourced from reputable manufacturers, users can expect a durable and cost-effective security measure that provides peace of mind in protecting their property. As the demand for robust fencing solutions continues to grow, electro galvanized barbed wire remains a favored choice worldwide.

1. Material Quality The quality of the steel and the galvanization process used significantly affect the price. Higher-grade steel and more thorough galvanization generally lead to a higher cost. Ensuring that nails meet necessary standards is crucial, especially in critical applications.

- However, despite its many benefits, hot dipped galvanized barbed wire does have some drawbacks. For example, it can be more expensive than other types of fencing materials, such as chain link or vinyl. Additionally, because of its sharp barbs, it can pose a risk to children and pets if not installed properly.

- Gauge Thickness The wire gauge is a measure of the wire’s thickness. A lower gauge number signifies thicker wire, which offers better security. For small birds, a wire gauge between 14 and 18 is generally recommended to ensure they cannot escape or get stuck.

Conclusion

Conclusion

The manufacturing of finishing nails involves several key steps, each crucial to ensuring the quality and durability of the final product. The process typically begins with the selection of high-quality steel wire, which is then cut to the appropriate lengths. The wire is heated and formed into a pointed nail shape through a series of mechanical processes, including forging and cutting.

The primary advantage of using fiberglass rods, whether at 3% or 4%, lies in their corrosion resistance. Unlike metal rods, fiberglass does not rust or corrode when exposed to moisture or chemicals, which significantly increases its longevity, especially in applications such as marine environments or chemical processing industries.

3 4 fiberglass rod

The Benefits and Features of a 300-Gallon Stainless Steel Water Tank

Fiberglass rods are composite materials made from a mixture of glass fibers and resin. This composite structure provides excellent strength-to-weight ratio, corrosion resistance, and flexibility. Fiberglass rods can come in various percentages of fiberglass concentration, and a 1.25% fiberglass rod denotes that the rod contains 1.25% fiberglass content relative to the total composite material. This lower concentration makes these rods particularly lightweight while still retaining essential strength characteristics.

Sulphur trioxide is formed when sulphur dioxide reacts with oxygen in a ratio of 1:1 at a temperature of 400 °C – 450°C and a pressure of 1-2 atm in the presence of V2O5 as a catalyst. This reaction is reversible in nature.

China is known for its manufacturing capabilities and the coil nail industry is no exception. With a growing demand for high-quality nails in construction and manufacturing, China Coil Nail Factory has positioned itself as a trusted supplier in the global market.

grp pipework. Because it is resistant to corrosion, GRP pipework can last for decades without the need for replacement or repair. This can result in significant cost savings over time, as well as reduce downtime and maintenance requirements.

grp pipework. Because it is resistant to corrosion, GRP pipework can last for decades without the need for replacement or repair. This can result in significant cost savings over time, as well as reduce downtime and maintenance requirements.Black steel nails are made from carbon steel, which is known for its strength and durability. The term black refers to the finish of the nails, which is a result of the manufacturing process that leaves a protective layer of iron oxide. This finish provides an aesthetic appeal and also enhances the nails' resistance to corrosion to some extent. However, it is important to note that while this protective layer aids in resisting rust, these nails are not fully rust-proof. Therefore, their use is best suited for indoor applications or in environments where they will not be exposed to excessive moisture.

However, it is essential to note that black steel iron wire requires adequate treatment to ensure longevity. The wire is typically coated with oil or other protective substances to prevent rusting, particularly when exposed to moisture. Proper maintenance and care can extend the lifespan of the wire, preserving its strength and appearance for years to come.

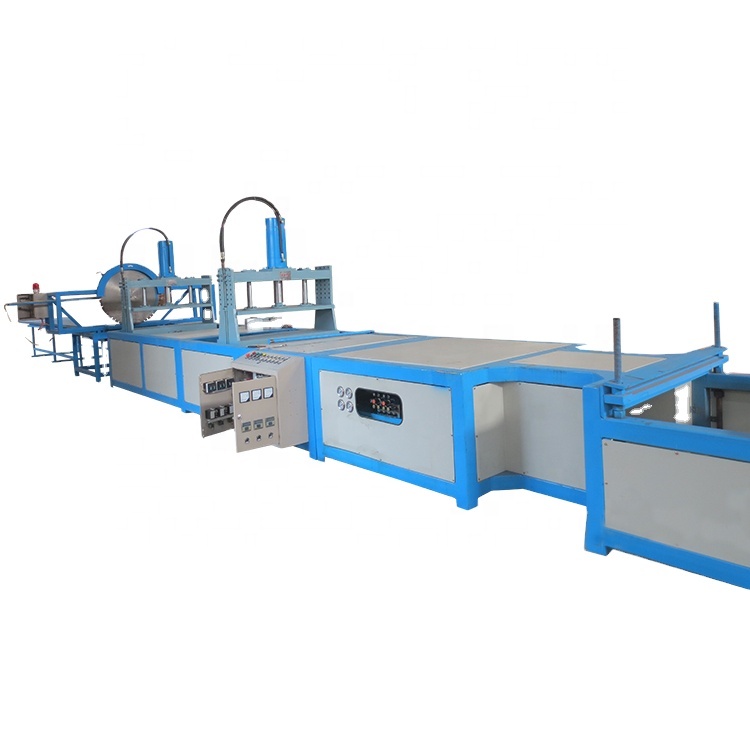

Pultrusion is a continuous manufacturing process that produces composite materials. This method is particularly popular for creating reinforced thermosetting resins, commonly used in a variety of applications including construction, automotive, and aerospace industries. One of the key considerations for businesses looking to invest in pultrusion technology is the cost associated with acquiring pultrusion machines. Understanding these costs is essential for making informed decisions regarding production capabilities and long-term financial planning.

2. Electrical and Telecommunications The non-conductive nature of fiberglass rods makes them perfect for electrical applications. They are used in the installation of overhead utility lines and as insulators. Moreover, they can be employed in telecommunications to support aerial cables.

1 4 inch fiberglass rod

Electric galvanized barbed wire is a crucial element in modern fencing systems, particularly valued for its durability, strength, and corrosion resistance. As the demand for reliable security and boundary solutions increases globally, this product has gained significant traction, particularly from manufacturers in China, renowned for their competitive prices and quality standards.

In today’s world, security and aesthetics are two paramount considerations for both residential and commercial properties. One of the most effective solutions that combines these features is the powder coated wire mesh fence. This type of fencing not only provides durability and strength but also adds an appealing finish that can enhance the beauty of any property. In this article, we will explore the various aspects and advantages of powder coated wire mesh fences.

The production of square wire mesh involves several steps that start with wire drawing and culminate in the weaving of the mesh. The process begins with the selection of raw materials, typically wire rods. These rods are drawn into thinner wires using drawing machines. The diameter of the wire can be adjusted to meet specific standards required for different applications.

Conclusion

Furthermore, electro galvanized barbed wire is easy to handle and install. It can be quickly and securely attached to existing structures, saving time and effort during the installation process. Whether used for temporary or permanent security measures, electro galvanized barbed wire provides a reliable solution that is easy to manage.

The Versatility and Importance of Concrete Cap Nails

1. Durability Concerns

In the modern industrial landscape, square wire mesh has become an essential product used across various industries, from construction and agriculture to manufacturing and security. The prevalence of square wire mesh factories is a testament to the increasing demand for this versatile material, which offers a myriad of applications due to its strength, durability, and flexibility.

Cost Factors for FRP Pipes

As industries increasingly focus on sustainability, many square wire mesh factories are adopting eco-friendly practices. This includes using recycled materials, implementing energy-efficient production processes, and optimizing waste management strategies. By prioritizing sustainability, these factories not only reduce their environmental footprint but also meet the growing demand for green products.

In summary, steel water tanks represent a vital component of modern water storage solutions. Their durability, versatility, and eco-friendly attributes make them an ideal choice for various applications. With concerns about water quality and sustainability on the rise, steel tanks offer a reliable means to ensure access to clean water for both people and industries. As we continue to face challenges related to water scarcity and environmental protection, investing in steel water tanks can pave the way for more efficient and responsible water management strategies worldwide.

grp cooling tower. This condensed water is then recycled back into the boiler to be reheated and reused, completing the cycle.

grp cooling tower. This condensed water is then recycled back into the boiler to be reheated and reused, completing the cycle.In summary, a 1000-litre steel tank represents a reliable and versatile storage solution across various sectors. Its construction guarantees durability, while its diverse applications highlight its importance in modern industry. The advantages of using such tanks, including cost efficiency, safety, and environmental sustainability, make them an indispensable asset for businesses and agricultural operations alike. As industries continue to evolve, the need for robust and dependable storage solutions like the 1000-litre steel tank will remain crucial. Investing in such infrastructure is not just a matter of necessity; it is a strategic decision that can enhance productivity and ensure the safe handling of materials.