china oem short delivery slurry pump factories

Latest articles

Larger impellers made of more material. This is to compensate for the wear caused by abrasive slurry.

china oem short delivery slurry pump factories...

china oem short delivery slurry pump factories 【china oem short delivery slurry pump factories】

Read More>Slurry Pump

china oem short delivery slurry pump factories...

china oem short delivery slurry pump factories 【china oem short delivery slurry pump factories】

Read MoreThe terms 'flushing' and 'quench' often seem to be confused or misused when discussing seal support schemes for >slurry pumps. As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

china oem short delivery slurry pump factories...

china oem short delivery slurry pump factories 【china oem short delivery slurry pump factories】

Read MoreSlurry Pump

china oem short delivery slurry pump factories...

china oem short delivery slurry pump factories 【china oem short delivery slurry pump factories】

Read MoreFor example.

china oem short delivery slurry pump factories...

china oem short delivery slurry pump factories 【china oem short delivery slurry pump factories】

Read MoreDredge Pump

china oem short delivery slurry pump factories...

china oem short delivery slurry pump factories 【china oem short delivery slurry pump factories】

Read MoreIf the exact in-pump viscosity of the product is unknown, CSI can help

china oem short delivery slurry pump factories...

china oem short delivery slurry pump factories 【china oem short delivery slurry pump factories】

Read MoreAnother way of classifying the type of slurry pump installation is dry installation or wet installation. Dry installation pumps have the hydraulic end and drive located outside the liquid, whereas wet installation pumps (such as submersible pumps) operate within a catch basin or slurry. Submersible pumps do not require much support structure and therefore do not take up much space. Depending on the type of operation and installation required, the preferred method of pump installation is determined.

china oem short delivery slurry pump factories...

china oem short delivery slurry pump factories 【china oem short delivery slurry pump factories】

Read MoreBCT Ceramic Slurry Pumps

china oem short delivery slurry pump factories...

china oem short delivery slurry pump factories 【china oem short delivery slurry pump factories】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

china oem short delivery slurry pump factories...

china oem short delivery slurry pump factories 【china oem short delivery slurry pump factories】

Read More

Popular articles

- Another way of classifying the type of slurry pump installation is dry installation or wet installation. Dry installation pumps have the hydraulic end and drive located outside the liquid, whereas wet installation pumps (such as submersible pumps) operate within a catch basin or slurry. Submersible pumps do not require much support structure and therefore do not take up much space. Depending on the type of operation and installation required, the preferred method of pump installation is determined.

- Materials of Construction

- Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

- Slurry pump power adjustment

- The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

- A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

Latest articles

-

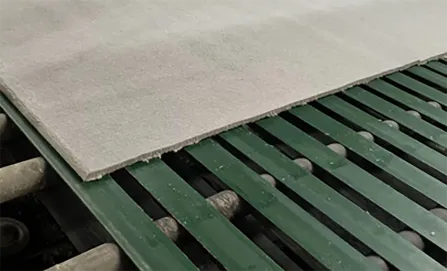

Dry Installation

-

WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

-

Quenching is defined as the introduction of a neutral fluid (usually water or steam) into the atmospheric side of the seal to prevent the formation of solids that may interfere with movement or be used for other purposes.

-

Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - usually 2-5 vanes.

-

Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

-

The Difference Between Flushing And Quenching in Slurry Pump Seals