high quality screw pump for slurry factory

Latest articles

A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

high quality screw pump for slurry factory...

high quality screw pump for slurry factory 【high quality screw pump for slurry factory】

Read MoreIf pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

high quality screw pump for slurry factory...

high quality screw pump for slurry factory 【high quality screw pump for slurry factory】

Read MoreFor example.

high quality screw pump for slurry factory...

high quality screw pump for slurry factory 【high quality screw pump for slurry factory】

Read MoreSlurry pump vs mud pump

high quality screw pump for slurry factory...

high quality screw pump for slurry factory 【high quality screw pump for slurry factory】

Read MoreSlurry Pump

high quality screw pump for slurry factory...

high quality screw pump for slurry factory 【high quality screw pump for slurry factory】

Read MoreWhat is a dredging pump?

high quality screw pump for slurry factory...

high quality screw pump for slurry factory 【high quality screw pump for slurry factory】

Read MoreWhat is a slurry?

high quality screw pump for slurry factory...

high quality screw pump for slurry factory 【high quality screw pump for slurry factory】

Read MoreSlurry pump considerations

high quality screw pump for slurry factory...

high quality screw pump for slurry factory 【high quality screw pump for slurry factory】

Read MoreMixers can also help agitators when pumping very dense particles. In applications where the tank is small and/or where pumping is desired to lower the water level in the tank, a slurry pump with an internal cooling system should be considered to avoid overheating of the stator (when the water level gets low). When pumping sediment from a dam or lagoon, consider the use of a raft unit, which is a submersible device. Agitators are recommended, as well as one or more mixers that can be mounted on the raft or pump to resuspend particles for successful pumping of particles.

high quality screw pump for slurry factory...

high quality screw pump for slurry factory 【high quality screw pump for slurry factory】

Read MoreSlurry Pump

high quality screw pump for slurry factory...

high quality screw pump for slurry factory 【high quality screw pump for slurry factory】

Read More

Popular articles

- Slurry Pump

- The mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

- Expertise and experience

- Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

- >Vertical Slurry Pump

- Slurry Pump

Latest articles

-

Slurry Pump Impeller Type

-

If you want to know more information about the best heavy duty slurry pump, welcome to >contact us today or request a quote.

-

How to Choose a Dredging Pump or Slurry Pump

-

What is a slurry pump?

-

A , slurry pump, is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

-

1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

Links

- Another popular shank type is the hex shank. Hex shanks have six flat sides that allow for a secure grip in a drill chuck, preventing slippage during use. This type of shank is commonly found on impact drivers and other power tools that require extra torque. The flat sides also make hex shanks easy to change out quickly, saving time on the job.

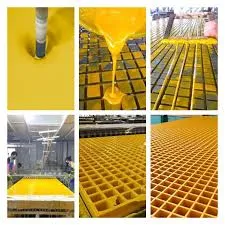

MOLDED FIBERGLASS GRATING

For a further details on mesh openings and panel sizes, please view our Sizes & Options.

fiber reinforced plastic tank. They can be molded into complex shapes, allowing for custom designs to meet specific application requirements. This adaptability extends to the choice of fiber and resin, which can be tailored to optimize properties such as strength, toughness, electrical conductivity, or thermal stability.

fiber reinforced plastic tank. They can be molded into complex shapes, allowing for custom designs to meet specific application requirements. This adaptability extends to the choice of fiber and resin, which can be tailored to optimize properties such as strength, toughness, electrical conductivity, or thermal stability. Carroll's use of stark contrast and minimalist design reflects Davis' departure from traditional jazz into electronic experimentation Carroll's use of stark contrast and minimalist design reflects Davis' departure from traditional jazz into electronic experimentation

Carroll's use of stark contrast and minimalist design reflects Davis' departure from traditional jazz into electronic experimentation Carroll's use of stark contrast and minimalist design reflects Davis' departure from traditional jazz into electronic experimentation grp cover. It's an image that provokes thought, much like the music itself.

grp cover. It's an image that provokes thought, much like the music itself. rock drilling companies. Their expertise spans across exploration, development, and operation of mines, making them a comprehensive service provider. BHP's focus on safety and responsible mining practices sets a benchmark for the industry.

rock drilling companies. Their expertise spans across exploration, development, and operation of mines, making them a comprehensive service provider. BHP's focus on safety and responsible mining practices sets a benchmark for the industry.

Gratings & Covers

fiberglass products for steel smelting plant. These are critical components used in the steelmaking process, and they require materials that can withstand high temperatures and corrosive conditions. Fiberglass crucibles and ladles are designed to provide long service life and superior performance in these demanding environments.

fiberglass products for steel smelting plant. These are critical components used in the steelmaking process, and they require materials that can withstand high temperatures and corrosive conditions. Fiberglass crucibles and ladles are designed to provide long service life and superior performance in these demanding environments.