china oem slurry pump engineering factory

Latest articles

When dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreSlurry Pump

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreWA Heavy-duty Slurry Pump

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreWhat we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. >Slurry pumps are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreDetermine the size of the pump

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreSlurry Pump

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreHow much solids damage can the customer tolerate?

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read More>Slurry Pump

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreFewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - usually 2-5 vanes.

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read MoreQuenching is defined as the introduction of a neutral fluid (usually water or steam) into the atmospheric side of the seal to prevent the formation of solids that may interfere with movement or be used for other purposes.

china oem slurry pump engineering factory...

china oem slurry pump engineering factory 【china oem slurry pump engineering factory】

Read More

Popular articles

- >TL FGD Pump

- Will solids size pass through the pump?

- In a subsea installation, the slurry pump runs directly in the slurry and does not require a support structure, which means it is flexible and easy to install. If possible, the catch basin should be equipped with sloping walls to allow sediment to slide down into the area directly below the pump inlet. Agitators should be used when the liquid contains large amounts of solids and has a high particle density. Freestanding or side-mounted (submersible) mixers are an excellent choice for resuspended solids, especially if the catch basin is large or does not have sloping walls.

- Compared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

- When slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

- Slurry Pump

Latest articles

-

Step 2

-

Better safety

-

Slurry Pump

-

What is the optimum seal arrangement for the application?

-

Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

-

Fine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

Links

Conclusion

- One of the most common uses for iron nails is in carpentry work. They are used to fasten wood pieces together and provide structural support to a variety of projects. Whether you are building a wooden fence, a bookshelf, or a deck, iron nails are essential for ensuring that your project stays together securely.

Is H2SO4 a Monoprotic acid?

Conclusion

1. Corrosion Resistance The zinc coating on electro-galvanized nails acts as a barrier against moisture and other corrosive elements. This property is especially vital when working with concrete, which can contain chemicals that may cause steel to corrode if exposed over time.

The price of pure iron nails varies based on several factors, including size, quantity, market demand, and suppliers. Generally, larger nails and specialized types, like those designed for specific applications, tend to be more expensive. Economic conditions and fluctuations in the raw materials market can also impact prices. For example, when the demand for iron spikes in the construction industry, it may lead to higher prices for pure iron nails.

In conclusion, small coil black iron is a versatile material that serves essential functions across multiple industries. Its strength, cost-effectiveness, and aesthetic appeal make it an ideal choice for both industrial applications and creative projects. As manufacturing processes continue to evolve, small coil black iron will likely remain a critical component of our infrastructure and artistic endeavors, showcasing the timeless nature of this remarkable material.

In commercial settings, square wire mesh fences can serve as security enclosures for warehouses, factories, and storage yards. The strength of the wire ensures that intruders are deterred, while the visibility of the fencing allows for light and air circulation, preventing a claustrophobic environment. With options for heights, thickness, and coatings, these fences can be tailored to meet specific security threats.

The use of tube fiberglass has become increasingly popular in recent years, as industries recognize the numerous benefits and advantages that this material offers. From aerospace and automotive engineering to construction and manufacturing, tube fiberglass has proven to be a valuable asset in enhancing performance and efficiency.

● The corrosion-resistant properties of composite materials provide a durable and low maintenance solution for products that are exposed to the weather. For example, pultruded roof trim, fascia, and soffit are lightweight and easy to install.

Their modular design allows for flexibility in configuring the ladder system according to specific site requirements, whether it's a straight run or a complex layout with multiple turns and levels Their modular design allows for flexibility in configuring the ladder system according to specific site requirements, whether it's a straight run or a complex layout with multiple turns and levels

Their modular design allows for flexibility in configuring the ladder system according to specific site requirements, whether it's a straight run or a complex layout with multiple turns and levels Their modular design allows for flexibility in configuring the ladder system according to specific site requirements, whether it's a straight run or a complex layout with multiple turns and levels fibreglass cable ladder.

fibreglass cable ladder.

razor wire. The sharp metal blades are resistant to weather elements, rust, and corrosion, ensuring that the fence remains effective and secure for long periods of time. This makes it an ideal choice for outdoor environments where other security measures may deteriorate over time.

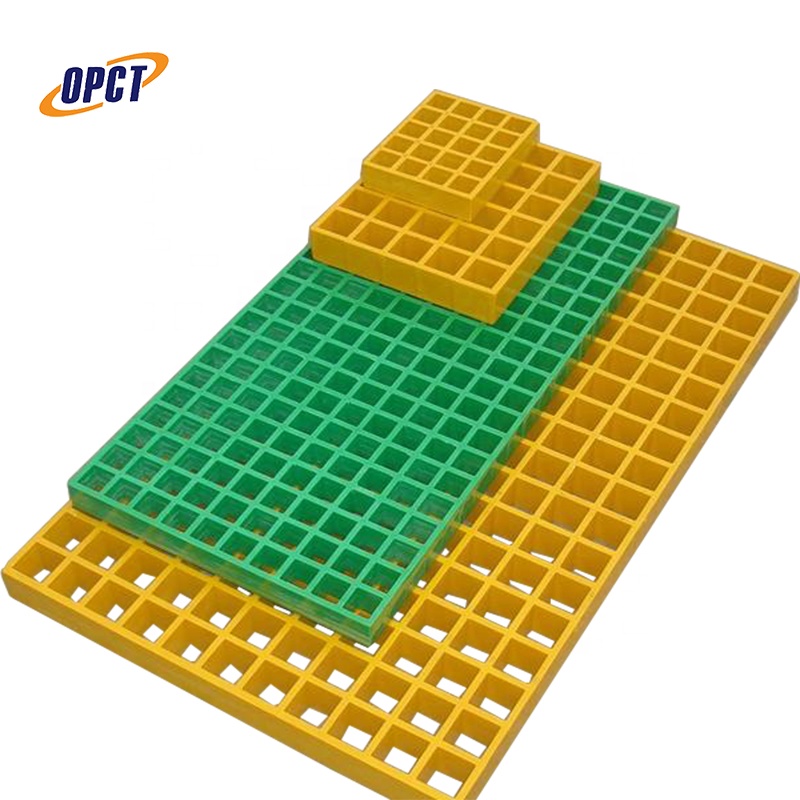

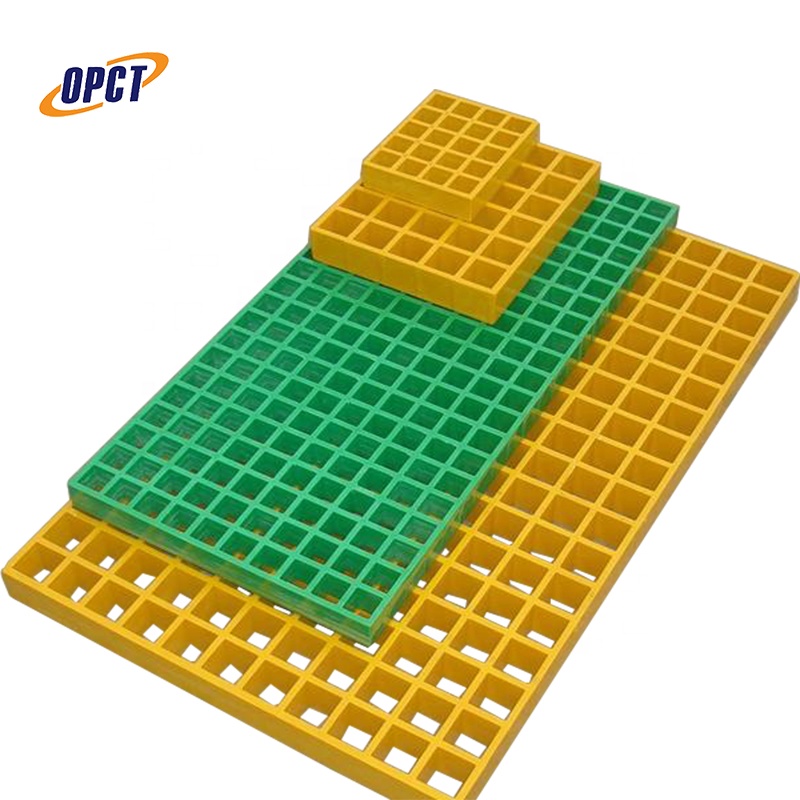

Advantages of GRP Cable Ladders

Overall, frp machines play a crucial role in the manufacturing industry, offering a cost-effective and efficient solution for producing high-quality composite products. With their lightweight, strong, and versatile properties, frp materials are an excellent choice for a wide range of applications. As technology advances and demand for composite materials grows, frp machines are likely to become even more popular in the future.

2. Lightweight and Easy to Handle Fiberglass pipes are considerably lighter than their metal counterparts. The reduced weight allows for easier handling during installation and maintenance, which can lead to decreased labor costs and faster project completion times. This is particularly beneficial in situations where manual handling is necessary and when working in confined or hard-to-reach spaces.

4. Design and Features

Craftsmen and hobbyists have also found innovative uses for plastic coated iron wire. Whether used in DIY projects, floral arrangements, or even art installations, this material aids in delivering creative freedom while maintaining integrity. Its ease of manipulation and availability in various colors make it a popular choice for both professional artists and amateurs.

1. Corrosion Resistance The zinc coating is highly effective at preventing rust, making galvanized rope ideal for use in environments where moisture is prevalent, such as marine and agricultural settings.

china galvanized rope

Finding the best prices for pure iron nails can be done through various channels. Online marketplaces, local hardware stores, and specialty suppliers are all viable options. In recent years, e-commerce has changed the way consumers shop for construction materials. Websites often provide comparative pricing, which allows buyers to easily identify competitive offers. Moreover, bulk purchasing can result in significant savings, making it an attractive option for contractors and large-scale projects.

Fiberglass exhibits excellent insulation properties, meaning it can help maintain the temperature of the water stored within. This is particularly useful in environments with extreme temperatures. By minimizing the impact of external temperature fluctuations, a fiberglass tank can help prevent water from freezing in colder climates and keep it cool in hotter regions. This thermal stability is an advantageous feature for agricultural applications or wherever temperature-sensitive water needs to be stored.

100 gallon fiberglass water tank

China galvanized rope has emerged as a popular choice in various industries due to its strength, durability, and resistance to corrosion. With the growing demand for reliable and long-lasting materials, galvanized wire rope manufactured in China has gained significant traction across global markets. This article aims to delve into the characteristics, benefits, applications, and manufacturing processes of galvanized rope, highlighting its importance in various sectors.

Durability and Longevity

Moreover, in varying environmental conditions, the quality and length of concertina wire are essential for maintaining effectiveness. In areas prone to harsh weather, longer and sturdier rolls can create a more resilient barrier against elements like wind, rain, and snow. Similarly, when improperly maintained, shorter sections can sag or become damaged more easily, leading to security vulnerabilities.

FRP is a composite material consisting of a polymer matrix reinforced with fibers, typically glass. This combination results in pipes that are not only robust but also versatile, making them suitable for a wide array of applications, including water treatment plants, chemical processing, oil and gas pipelines, and cooling water systems.

Characteristics of Common Nails

What is Fiberglass Pipe?

3. Automotive Industry The automotive sector also benefits from the properties of black square tubes. They are utilized in manufacturing various vehicle components, such as chassis, frames, and support structures, where robustness and reliability are critical.

Easy installation Roofing wire mesh is relatively easy to install, requiring only basic tools and skills Easy installation Roofing wire mesh is relatively easy to install, requiring only basic tools and skills

Easy installation Roofing wire mesh is relatively easy to install, requiring only basic tools and skills Easy installation Roofing wire mesh is relatively easy to install, requiring only basic tools and skills roofing wire mesh.

roofing wire mesh.Social media platforms like Instagram and TikTok have further fueled the nail art trend. Influencers and enthusiasts share tutorials, tips, and their latest designs, inspiring countless others to experiment with their nails. The hashtag NailArt has millions of posts, showcasing the creativity and talent of nail artists worldwide. Online tutorials have made it accessible for anyone to learn and perfect their nail art skills at home.