mini dredge pump manufacturer

Latest articles

Selecting the right pump for slurries is critical to get the most bang for your buck. Basic pump components, such as the impeller size and design, material of construction, and discharge configurations must be considered to ensure the pump will hold up against the wear caused by an abrasive slurry. Slurry pumps are generally larger in size when compared to low-viscosity liquid pumps and usually require more horsepower to operate because they're less efficient. Bearings and shafts must be more rugged and rigid as well.

mini dredge pump manufacturer...

mini dredge pump manufacturer 【mini dredge pump manufacturer】

Read MoreA slurry is a mixture of fluids, which consists of a water-like liquid and particles. Typically, slurry acts in the same way as a viscous, sticky fluid - moving with gravity - but usually needs to be pumped.

mini dredge pump manufacturer...

mini dredge pump manufacturer 【mini dredge pump manufacturer】

Read MoreThe terms flushing and quench, often seem to be confused or misused when discussing seal support schemes for , slurry pumps, . As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

mini dredge pump manufacturer...

mini dredge pump manufacturer 【mini dredge pump manufacturer】

Read MorePumping slurry can cause excessive wear and tear on the pump and its components as the mud can clog the suction and discharge lines.

mini dredge pump manufacturer...

mini dredge pump manufacturer 【mini dredge pump manufacturer】

Read MoreChoosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

mini dredge pump manufacturer...

mini dredge pump manufacturer 【mini dredge pump manufacturer】

Read MoreAs a pump supplier, Aier is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc. If you want to get more information about >best slurry pump wholesale, welcome to >contact us today or request a quote.

mini dredge pump manufacturer...

mini dredge pump manufacturer 【mini dredge pump manufacturer】

Read MoreA quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

mini dredge pump manufacturer...

mini dredge pump manufacturer 【mini dredge pump manufacturer】

Read MoreHow Slurry Pumps Differ From Standard Pumps?

mini dredge pump manufacturer...

mini dredge pump manufacturer 【mini dredge pump manufacturer】

Read Morehow-does-a-dredge-pump-work

mini dredge pump manufacturer...

mini dredge pump manufacturer 【mini dredge pump manufacturer】

Read Moretarget=_blank title=Rubber Liner Pumps>Rubber liner pumps have been used for nearly a century to protect plants and equipment from wear and retain their place as the wear material of choice for pumping and separating fine-grained slurries.

mini dredge pump manufacturer...

mini dredge pump manufacturer 【mini dredge pump manufacturer】

Read More

Popular articles

- To reduce wear, reduce the pump discharge pressure to the lowest possible point.

- A target=_blank title=Slurry Pump>slurry pump is a special type of pump capable of handling slurry. Unlike water pumps, slurry pumps are prone to wear and tear and are more robust and durable.

- Step 4

- If you want to know more information about the best slurry pumps wholesale, welcome to >contact us today or request a quote.

- WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

- The FGD process begins when the limestone feed (rock) is reduced in size by crushing it in a ball mill and then mixed with water in a slurry supply tank. The slurry (approx. 90% water) is then pumped into the absorption tank. As the consistency of the limestone slurry tends to change, suction conditions can occur which can lead to cavitation and pump failure.

Latest articles

-

Working principle

-

How to choose a slurry pump?

-

Traditionally, centrifugal pumps are used to pump highly abrasive slurries. Centrifugal pumps use the force generated by the rotating impeller to impinge kinetic energy into the slurry.

-

What is a dredging pump?

-

Many types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

-

The dredge pump is designed to draw sediment, debris and other hazardous materials from the surface layer into the suction pipe and transport the material through the pipe to the discharge site. The pump must be able to handle common solid debris of various sizes that can pass through the pump, thus minimizing the downtime required for cleaning.

Links

- 2. Types of Floor Line Marking Tape

Compared to acrylic and rubber adhesives, they are significantly more expensive, but due to their excellent high temperature performance they are very well suited to splicing tapes, masking tapes and polyimide (Kapton) tapes.

- In conclusion, Flex Tape in white is a game-changer in the world of DIY repairs. With its unmatched strength, ease of use, versatility, and cost-effectiveness, this innovative product is the ultimate solution for all your repair needs. So why settle for anything less when you can have the best? Try Flex Tape in white today and experience the difference for yourself.

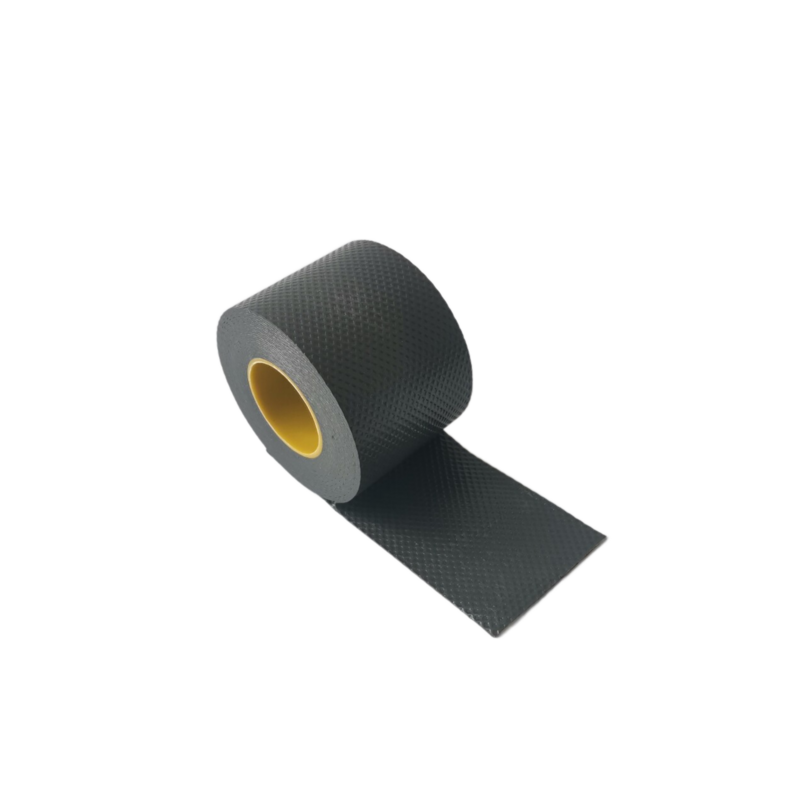

- PVC insulation electrical tape, also known as vinyl electrical tape, is an essential tool in the world of electrical wiring and maintenance. This versatile and widely-used material plays a crucial role in ensuring safety and efficiency in various electrical applications. Its significance lies in its ability to insulate, protect, and secure electrical wires and connections.

self fusing rubber tape. Once applied, it can withstand years of wear and tear without losing its adhesive properties. This makes it a cost-effective solution for long-lasting repairs and installations.

7. Easy to use: a layer of Self Fusing tape can play a good insulation role and reduce labor and cost.

butyl tape rubber.

Polyethylene Film Tape 7 Mil UV 60 Yd

Moreover, the aesthetic aspect of Black Flex Tape cannot be overlooked. With its sleek black appearance, it blends seamlessly into many environments, providing a discreet solution for unsightly repairs. This visual appeal is particularly important for those looking to maintain the integrity and appearance of their personal belongings or living spaces.