oem heavy duty slurry pump manufacturers

Latest articles

What is slurry?

oem heavy duty slurry pump manufacturers...

oem heavy duty slurry pump manufacturers 【oem heavy duty slurry pump manufacturers】

Read MoreWhy would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

oem heavy duty slurry pump manufacturers...

oem heavy duty slurry pump manufacturers 【oem heavy duty slurry pump manufacturers】

Read More- Pumping media where abrasive particles are present

oem heavy duty slurry pump manufacturers...

oem heavy duty slurry pump manufacturers 【oem heavy duty slurry pump manufacturers】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

oem heavy duty slurry pump manufacturers...

oem heavy duty slurry pump manufacturers 【oem heavy duty slurry pump manufacturers】

Read MoreAbrasive.

oem heavy duty slurry pump manufacturers...

oem heavy duty slurry pump manufacturers 【oem heavy duty slurry pump manufacturers】

Read MoreLifetime use

oem heavy duty slurry pump manufacturers...

oem heavy duty slurry pump manufacturers 【oem heavy duty slurry pump manufacturers】

Read MoreDetermine the perfect combination of slow pumping (to reduce wear) and fast pumping to prevent solids from settling and clogging.

oem heavy duty slurry pump manufacturers...

oem heavy duty slurry pump manufacturers 【oem heavy duty slurry pump manufacturers】

Read MoreRubber lined pumps offer many advantages

oem heavy duty slurry pump manufacturers...

oem heavy duty slurry pump manufacturers 【oem heavy duty slurry pump manufacturers】

Read More>Slurry Pump

oem heavy duty slurry pump manufacturers...

oem heavy duty slurry pump manufacturers 【oem heavy duty slurry pump manufacturers】

Read MoreSlurry pumps can be used for.

oem heavy duty slurry pump manufacturers...

oem heavy duty slurry pump manufacturers 【oem heavy duty slurry pump manufacturers】

Read More

Popular articles

- Dredge Pump Features

- If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

- As the slurry is collected at the bottom of the tower, more rubber lined pumps are required to transfer the slurry to storage tanks, tailings ponds, waste treatment facilities or filter presses. Depending on the type of FGD process, other pump models are available for slurry discharge, pre-scrubber recovery and catch basin applications.

- The company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

- Depending on the abrasive nature of the slurry, it is important to select the ideal seal. Slurry pump seals should have a hardened surface made of silicon carbide or tungsten carbide. Vortex pumps use patented seal technology that utilizes a double mechanical seal setup and a separate seal flushing system. This allows the sealing surface to be kept cool at all times without causing the slurry to overheat the seal and crack the surface.

- Slurry Pump

Latest articles

-

Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

-

1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

-

>Dredge Pump

-

Slurry Pump Impeller

-

WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

-

Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

Links

- Layering these two elements creates not just a bed but a work of art that reflects your personality and brings joy to your daily routine. As you tuck yourself in at night, wrapped in the softness of your duvet insert and the elegance of your duvet cover, you'll understand why this simple combination is the epitome of comfort and style.

A bed skirt’s “drop” refers to the length of the skirt from the top of the box spring to the floor, stopping about ¼” from the floor.

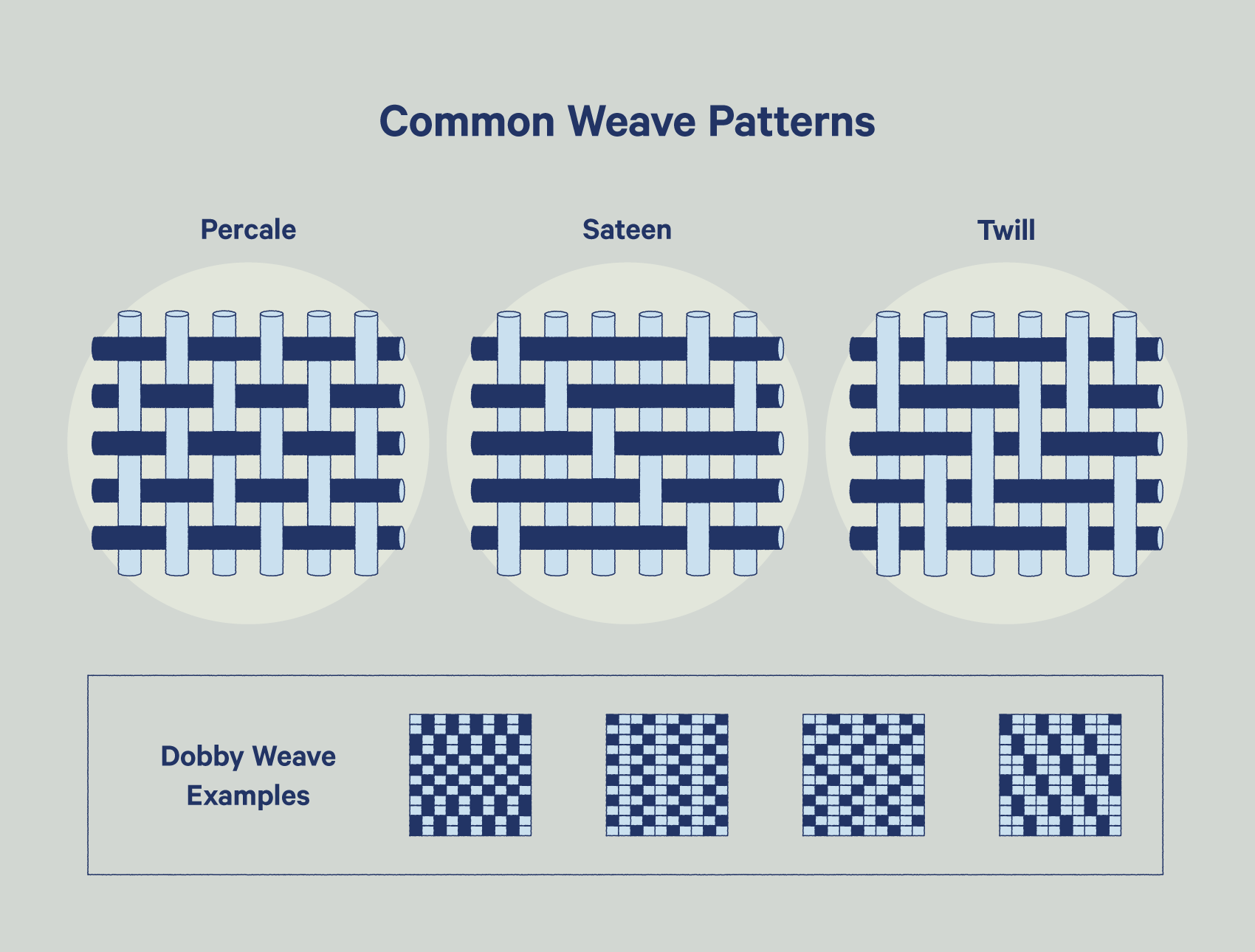

5. Jersey

Their durability is another plus point, as they withstand regular washing and maintain their glossy finish for a long time Their durability is another plus point, as they withstand regular washing and maintain their glossy finish for a long time

Their durability is another plus point, as they withstand regular washing and maintain their glossy finish for a long time Their durability is another plus point, as they withstand regular washing and maintain their glossy finish for a long time high quality satin sheets.

high quality satin sheets.From £50.00Shop now

3. Microfiber

Bamboo bedsheets are another eco-friendly option known for their softness and breathability.

For a more layered and luxurious look, add a Bed Valance to the bed.

A well-made bed sheet with a moderate thread count can still provide excellent comfort and durability A well-made bed sheet with a moderate thread count can still provide excellent comfort and durability

A well-made bed sheet with a moderate thread count can still provide excellent comfort and durability A well-made bed sheet with a moderate thread count can still provide excellent comfort and durability bed sheet thick.

bed sheet thick.

Crazy soft and naturally wrinkle-resistant weave.

Appearance

pack and play sheets. First, make sure to choose sheets that are made of soft, breathable fabric. This will help to keep your baby comfortable while they sleep and reduce the risk of overheating. Look for sheets that are machine washable and easy to clean, as accidents are bound to happen with young children.

In addition to the yarn count, the hotel sheets fabric used is also crucial. Cotton is the most popular choice for hotel sheets because of its breathability, softness, and durability. Egyptian or Pima cotton is often favored for its long fibers, which make hotel sheets finer, smoother, and more luxurious. Not only are these high-quality cotton hotel sheets comfortable, they stand up to frequent washing and retain their softness over time.