high quality excavator dredge pump

Latest articles

Slurry Pump

high quality excavator dredge pump...

high quality excavator dredge pump 【high quality excavator dredge pump】

Read MoreTwo types of slurry are found in these industries.

high quality excavator dredge pump...

high quality excavator dredge pump 【high quality excavator dredge pump】

Read More1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

high quality excavator dredge pump...

high quality excavator dredge pump 【high quality excavator dredge pump】

Read More>Slurry Pump

high quality excavator dredge pump...

high quality excavator dredge pump 【high quality excavator dredge pump】

Read MoreNatural rubber is an excellent wear material when handling wet sand slurries. Its strength, resilience and cut resistance have a positive impact on the wear performance of slurry pumps.

high quality excavator dredge pump...

high quality excavator dredge pump 【high quality excavator dredge pump】

Read MoreWhat style of pump is suitable?

high quality excavator dredge pump...

high quality excavator dredge pump 【high quality excavator dredge pump】

Read MoreDetermine the perfect combination of slow pumping (to reduce wear) and fast pumping to prevent solids from settling and clogging.

high quality excavator dredge pump...

high quality excavator dredge pump 【high quality excavator dredge pump】

Read MoreThese mud pumps can pump not only sand, but also more mud. They are very effective in pumping all forms of mud, gravel, concrete, slurry, slush, etc.

high quality excavator dredge pump...

high quality excavator dredge pump 【high quality excavator dredge pump】

Read MoreThe basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

high quality excavator dredge pump...

high quality excavator dredge pump 【high quality excavator dredge pump】

Read MoreIt is important that the pump you choose has components that will not wear out from abrasive slurries.

high quality excavator dredge pump...

high quality excavator dredge pump 【high quality excavator dredge pump】

Read More

Popular articles

- It is often used if a short period of dry running is expected. Fluid is introduced into the area between the back of the seal face and the tight-fitting outlet on the drive side of the slurry pump.

- As this limestone slurry needs to be moved efficiently through a complex industrial process, the selection of the right pumps and valves (taking into account their whole life cycle costs and maintenance) is crucial.

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- 1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

- Slurry Pump

- Positive displacement slurry pumps with limited capacity to deliver high head are used to pump slurry through pipes with very high solids concentrations.

Latest articles

-

- Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

-

When dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

-

On the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

-

These conditions include

-

Abrasive.

-

- Easy installation - Submersible pumps are relatively easy to install since the motor and worm gear are a single unit.

Links

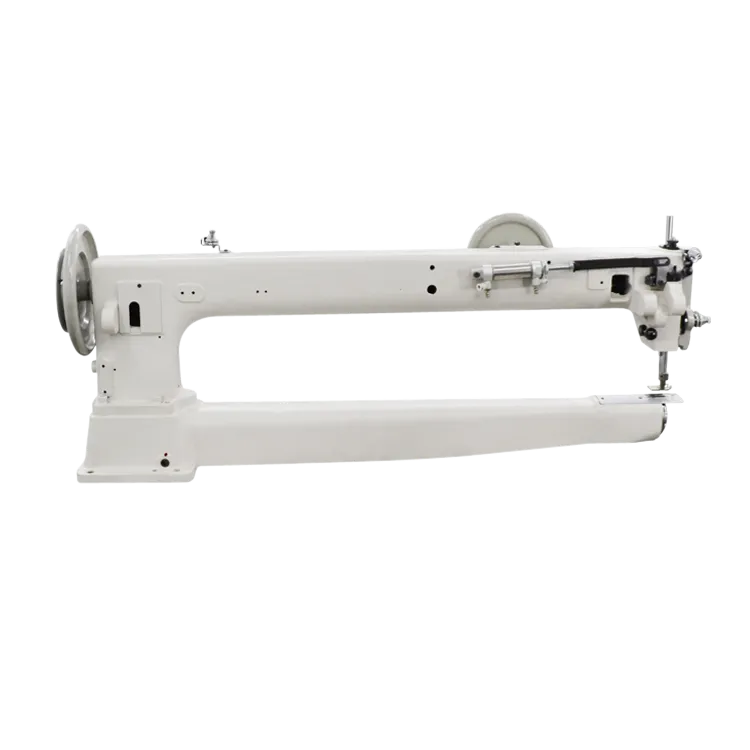

Understanding FIBC Sewing Machine Heads

- Finally, don't forget about the size and weight of the sewing machine. Leather and canvas projects can be bulky and heavy, so you'll want a machine that is stable and easy to maneuver. Look for a machine that is heavy enough to stay in place while sewing but not too heavy to move around when needed.

- One of the key features of a heavy-duty mechanical sewing machine is its strong motor. This motor is capable of generating high-speed stitching, allowing for quick and efficient sewing. Heavy-duty machines also often come with a variety of stitch options and adjustable tension settings, giving users greater control over their stitching projects.

3. Construction Quality

User-Friendliness

What is a Zigzag Stitch?

The applications of the double needle stretch stitch are extensive. In fashion, you will find it being used for hems on t-shirts, leggings, and swimsuits, as it provides a professional finish while allowing the garment to maintain its stretch. Additionally, home sewers can take advantage of this stitch when creating costume pieces, pajamas, or any project that incorporates knit fabrics.

A Brief History

The Advantages of Automatic Needle Threader Sewing Machines

- - Versatility While excellent for leather, many heavy-duty machines can also handle other materials such as denim and canvas, making them versatile additions to your sewing arsenal.

3. Choosing the Right Thread