china impeller dredge pump manufacturers

Latest articles

Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

china impeller dredge pump manufacturers...

china impeller dredge pump manufacturers 【china impeller dredge pump manufacturers】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

china impeller dredge pump manufacturers...

china impeller dredge pump manufacturers 【china impeller dredge pump manufacturers】

Read MoreAnother important target=_blank title=Part of the Slurry Pump>part of the slurry pump is its casing, which bears all the pressure. The slurry pump casing should have a large clearance between the impeller and the diversion angle to reduce wear and prevent large solid particles from getting stuck. Due to the extra space, there is more recirculation in the slurry pump casing under various operating conditions. Again, this accelerates wear compared to typical pumps.

china impeller dredge pump manufacturers...

china impeller dredge pump manufacturers 【china impeller dredge pump manufacturers】

Read More>Slurry Pump vs Mud Pump

china impeller dredge pump manufacturers...

china impeller dredge pump manufacturers 【china impeller dredge pump manufacturers】

Read More1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

china impeller dredge pump manufacturers...

china impeller dredge pump manufacturers 【china impeller dredge pump manufacturers】

Read MoreFewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - usually 2-5 vanes.

china impeller dredge pump manufacturers...

china impeller dredge pump manufacturers 【china impeller dredge pump manufacturers】

Read MoreWhat is the pump constructed of?

china impeller dredge pump manufacturers...

china impeller dredge pump manufacturers 【china impeller dredge pump manufacturers】

Read MoreSlurry Pump Selection

china impeller dredge pump manufacturers...

china impeller dredge pump manufacturers 【china impeller dredge pump manufacturers】

Read MoreFind a professional slurry pump supplier

china impeller dredge pump manufacturers...

china impeller dredge pump manufacturers 【china impeller dredge pump manufacturers】

Read MoreAs described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

china impeller dredge pump manufacturers...

china impeller dredge pump manufacturers 【china impeller dredge pump manufacturers】

Read More

Popular articles

- Definition of dredge and slurry pumps

- Working principle

- Improved flow control

- Dredge Pump

- When the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

- The slurry weight or consistency determines the type, design and capacity of the slurry pump required. If you have any questions about the best pump for your application, welcome to >contact us today or request a quote.

Latest articles

-

Submersible Slurry Pump

-

It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

-

The terms 'flushing' and 'quench' often seem to be confused or misused when discussing seal support schemes for >slurry pumps. As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

-

Fine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

-

WA Heavy-duty Slurry Pump

-

>Slurry pumps are typically larger than standard pumps, with more horsepower and stronger bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids move through a standard centrifugal pump.

Links

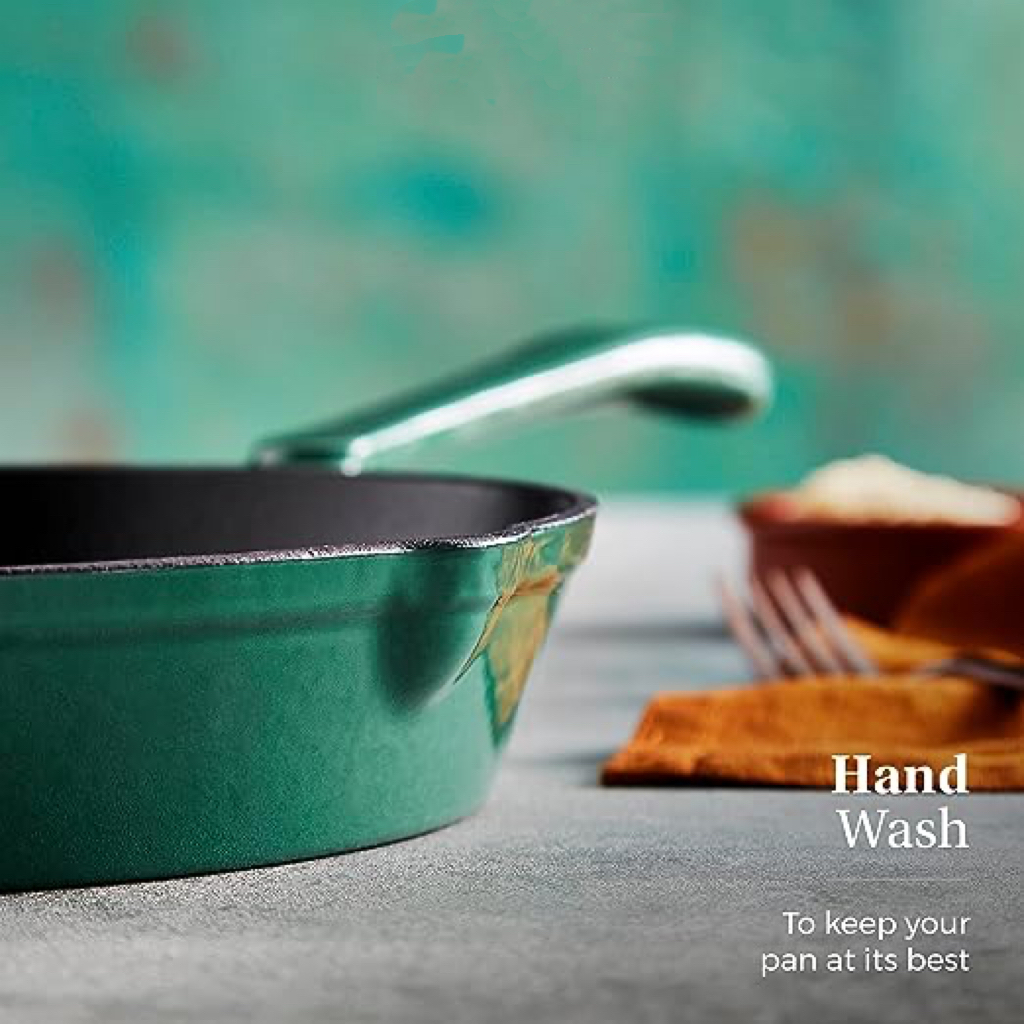

- One of the biggest advantages of using a cast iron Dutch oven for grilling is its excellent heat retention and distribution. Cast iron is known for its ability to hold and evenly distribute heat, making it perfect for grilling a wide variety of foods. Whether you're cooking over an open flame, on a charcoal grill, or even in your backyard smoker, a cast iron Dutch oven will help you achieve perfectly cooked and delicious results every time.

The difference in shape affects five main factors: surface area, volume, weight, tossing ability, and evaporation.

The weight difference between frypans and skillets can vary depending on the size and material used to construct the cookware. As a general rule, frypans are the lighter option between the two.

sizzling plate for sale. The plate allows for creative cooking methods, such as searing meats or frying vegetables directly on the plate, thus infusing the food with a rich, smoky flavor. Additionally, the aesthetic appeal of serving food on a sizzling plate can transform any dinner party into an elegant affair.

sizzling plate for sale. The plate allows for creative cooking methods, such as searing meats or frying vegetables directly on the plate, thus infusing the food with a rich, smoky flavor. Additionally, the aesthetic appeal of serving food on a sizzling plate can transform any dinner party into an elegant affair.Restoring enamel cookware requires patience and care, but the right repair and maintenance can rejuvenate enamel cookware and extend its life. As a cast iron cookware manufacturer, we are committed to providing our customers with high-quality products and services.

Frying pans are usually made from various materials, including cast iron, stainless steel, aluminium, and copper. Each material has unique properties that make it suitable for specific types of cooking.

cast iron round dutch oven. It can go from stovetop to oven without missing a beat, allowing for searing and then slow cooking in one convenient piece of cookware. It's also incredibly energy-efficient, retaining heat so well that once it's hot, it requires less energy to maintain temperature than other types of cookware.

cast iron round dutch oven. It can go from stovetop to oven without missing a beat, allowing for searing and then slow cooking in one convenient piece of cookware. It's also incredibly energy-efficient, retaining heat so well that once it's hot, it requires less energy to maintain temperature than other types of cookware. The non-stick coating also prevents food from burning, reducing the chances of unwanted smoke and burnt flavors The non-stick coating also prevents food from burning, reducing the chances of unwanted smoke and burnt flavors

The non-stick coating also prevents food from burning, reducing the chances of unwanted smoke and burnt flavors The non-stick coating also prevents food from burning, reducing the chances of unwanted smoke and burnt flavors non stick enamel cookware.

non stick enamel cookware.Saute pans have straight sides instead of slanted ones, so a higher volume of ingredients or liquid can fit inside, making this style pan ideal for making sauces. Because of the design, sauces don't splash or slosh around as much, making clean-up a lot easier. Another bonus of this pan style is that most saute pans have a fitted lid, which reduces evaporation. These pans are well-suited for cooking methods such as braising, searing, or shallow-frying. But saute pans are heavier due to a wider base, making skillets easier to lift and move.

Some brands have been producing cast iron cookware for centuries and have built a reputation for their exceptional craftsmanship and quality Some brands have been producing cast iron cookware for centuries and have built a reputation for their exceptional craftsmanship and quality

Some brands have been producing cast iron cookware for centuries and have built a reputation for their exceptional craftsmanship and quality Some brands have been producing cast iron cookware for centuries and have built a reputation for their exceptional craftsmanship and quality cast iron skillet price. These brands often charge a premium for their products due to their heritage and commitment to excellence. Moreover, some cast iron skillets come with unique features such as assist handles or intricate designs, which can also increase their price.

cast iron skillet price. These brands often charge a premium for their products due to their heritage and commitment to excellence. Moreover, some cast iron skillets come with unique features such as assist handles or intricate designs, which can also increase their price.Previously the word skillet was mostly used for frying pans manufactured of cast iron. Saying skillet, people implied the one of this material. However, the phrase cast iron frying pan is also quite common. That is why the two terms have become interchangeable. Both skillets & frying pans refer to the same types of pan, and there is no need to look for features to distinguish between them.

So, both of them have:

123123