china pond dredge pump manufacturers

Latest articles

Choosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

china pond dredge pump manufacturers...

china pond dredge pump manufacturers 【china pond dredge pump manufacturers】

Read More1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

china pond dredge pump manufacturers...

china pond dredge pump manufacturers 【china pond dredge pump manufacturers】

Read MoreSlurry pump power adjustment

china pond dredge pump manufacturers...

china pond dredge pump manufacturers 【china pond dredge pump manufacturers】

Read MoreThese conditions include

china pond dredge pump manufacturers...

china pond dredge pump manufacturers 【china pond dredge pump manufacturers】

Read More>Slurry Pump

china pond dredge pump manufacturers...

china pond dredge pump manufacturers 【china pond dredge pump manufacturers】

Read More- transport solids hydraulically

china pond dredge pump manufacturers...

china pond dredge pump manufacturers 【china pond dredge pump manufacturers】

Read MoreCarbon transfer

china pond dredge pump manufacturers...

china pond dredge pump manufacturers 【china pond dredge pump manufacturers】

Read MoreSlurry pumps are usually larger than standard pumps, have more horsepower and use stronger bearings and shafts. The most common >type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids pass through a standard centrifugal pump.

china pond dredge pump manufacturers...

china pond dredge pump manufacturers 【china pond dredge pump manufacturers】

Read MoreAdapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

china pond dredge pump manufacturers...

china pond dredge pump manufacturers 【china pond dredge pump manufacturers】

Read MoreThe construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

china pond dredge pump manufacturers...

china pond dredge pump manufacturers 【china pond dredge pump manufacturers】

Read More

Popular articles

- Slurry pumps can be used for.

- Our firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

- Find a professional slurry pump supplier

- Slurry Pump

- There is a better way to pump sewage, overflows and other collected dirty water around the plant.

- Dredge Pump

Latest articles

-

reduce the discharge pressure of the pump to the lowest possible point, and.

-

Pumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

-

Discharge ports can be placed at 45 degree intervals and oriented in up to 8 different positions depending on your needs.

-

3. Both pumps and motors are designed separately.

-

- By increasing the size of the worm housing, the speed at which the media moves is reduced. This lower velocity translates into lower wear.

-

The size of slurry pump impeller must be considered to ensure it holds up against abrasive wear. Slurry pump impellers are generally larger in size when compared to slurry pumps for less abrasive liquids. The more “meat” the impeller has, the better it will hold up to the task of pumping harsh slurry mixtures. Just think of slurry pump impeller as a football team’s offensive line. These players are usually large and slow. Throughout the whole game they are beaten up, over and over again, but expected to withstand the abuse. You wouldn’t want small players in this position, just like you wouldn’t want a small impeller on your slurry pumps.

One of the key features of a HD sewing machine is its strong motor, which provides the extra power needed to sew through tough materials. This means you can confidently tackle heavy-duty sewing tasks without worrying about your machine struggling or breaking down. The sturdy construction of a HD sewing machine also contributes to its longevity, ensuring that it will be a reliable companion for many years to come.

hd sewing machine

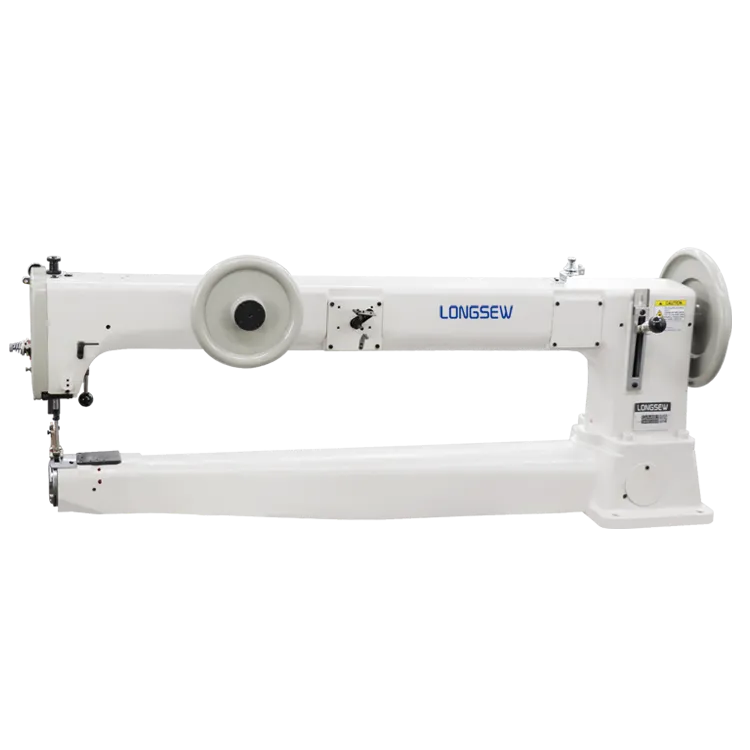

One of the key benefits of a long arm walking foot sewing machine is its versatility. Whether you are working on intricate quilting designs or simple sewing tasks, this type of machine can handle it all. Many models are equipped with multiple stitch options, allowing users to customize their projects to suit their personal style and preferences. Additionally, several machines come with built-in features such as automatic thread cutting, adjustable speed control, and stitch length adjustments, making the sewing process not only smoother but also more enjoyable.

long arm walking foot sewing machine for sale

- Ease of Use If you are new to upholstery, opt for a machine that is user-friendly with clear instructions. Additionally, look for models that offer good customer support and readily available parts.

6. Motor and Drive System The motor powers the various moving parts of the bag closer machine. A high-quality motor is essential for maintaining consistent speed and ensuring that the machine operates smoothly. The drive system connects the motor to the moving parts, translating electrical energy into mechanical motion.

In the world of garment manufacturing and textile production, efficiency and precision are paramount. One type of sewing machine that has become increasingly popular among professionals is the cylinder bed sewing machine. For those seeking to enhance their sewing operations, there are numerous cylinder bed sewing machines for sale, each offering unique advantages that cater to specific sewing needs.

Starting Projects

The Art of Single Needle Stitch A Timeless Technique

4. Professional Results For those looking to produce high-quality work, heavy-duty sewing and embroidery machines offer precision and strength in their stitching. The ability to manage thicker threads and heavier fabrics translates to professional results, making them a preferred choice for many designers and crafters.

2. Improved Load Capacity With the added strength of lock stitches, jumbo bags can handle greater loads without compromising integrity. This means manufacturers can safely transport larger quantities of materials, improving efficiency in logistics and reducing transportation costs.

Cylinder arm sewing machines are specifically designed for tasks that involve sewing cylindrical or tubular items. Unlike flatbed sewing machines, which have a flat working surface, cylinder arm machines feature a narrow, cylindrical arm that allows for easy maneuvering of items like cuffs, sleeves, bags, and footwear. This design is particularly beneficial for sewing projects that require access to hard-to-reach areas.One of the primary applications of cylinder arm sewing machines is in the production of garments and accessories. These machines are ideal for attaching sleeves, sewing cuffs, and hemming pants, as their cylindrical design allows for easy handling of these curved or tubular pieces. They are also commonly used in the manufacturing of bags, as the narrow arm makes it easier to sew around the edges and corners of the bag, ensuring neat and precise stitches.Another significant application is in the footwear industry. Cylinder arm sewing machines are perfect for sewing around the contours of shoes, particularly for attaching soles and decorative stitching. Their ability to handle thick and tough materials like leather and canvas makes them indispensable in the production of high-quality footwear. Additionally, these machines are used in the creation of other leather goods, such as belts, wallets, and upholstery.

When it comes to sewing heavy materials like canvas, having the right equipment can make all the difference. Heavy-duty sewing machines are designed to handle the thickness and toughness of materials such as canvas, leather, and denim. These machines are not only built to withstand the rigorous demands of heavy fabrics but also provide the precision and efficiency needed for a variety of sewing projects.

A walking foot is a type of presser foot that features an additional set of feeding mechanisms on top of the fabric. Unlike standard presser feet that rely solely on the machine’s feed dogs to move the fabric beneath the needle, the walking foot grips the fabric from above and moves it in sync with the feed dogs below. This dual feeding action prevents slippage and ensures that all layers of fabric are fed evenly through the machine, which is particularly helpful when sewing thick or textured materials.

The Floating Foot Sewing Machine Revolutionizing the Craft of Sewing

When selecting a sewing machine quilt pattern, consider factors such as your skill level, the type of fabric you want to use, and the overall look you hope to achieve. For beginners, simple block patterns or straight-line designs can be an excellent starting point. More advanced quilters may want to explore intricate patterns such as applique, paper piecing, or curves.

In the world of crafting and tailoring, the tools we choose can make all the difference. For leatherworkers, having a reliable and efficient sewing machine is paramount to achieving high-quality results. Among the various options available, the Cub Leather Sewing Machine stands out for its impressive capabilities tailored specifically for leather projects. This article explores the features, benefits, and applications of the Cub Leather Sewing Machine, making it an ideal choice for both amateur and professional leather crafters.

The thread is an often-overlooked component in the sewing process. However, it is crucial, especially when dealing with light fabrics. Heavy-duty machines are designed to handle thicker threads used for robust materials, but using such threads on delicate fabrics can result in puckering or even tearing.

Benefits of Lock Sewing

- Canvas and Outdoor Gear For items exposed to the elements, such as tents, tarps, or outdoor gear, using heavy duty needles ensures that stitches remain intact and secure.

What is an Industrial Serger Machine?

Conclusion

If you're in the market for a heavy-duty leather sewing machine, you’re likely aware of the importance of having the right tools for your leatherworking projects. Whether you’re a seasoned professional or a hobbyist working on leather goods, a reliable sewing machine specifically designed for heavy materials can make a world of difference in the quality and efficiency of your work.

Why Choose a Handheld Sewing Machine?

Exploring the Single Needle Edge Cutter Machine A Vital Tool in the Textile Industry

What is a Walking Foot Sewing Machine?

I started by surfing product review sites for advice. The Singer Heavy Duty quickly emerged as the champ, with a bigger motor and stronger metal frame allowing you to tackle thicker fabrics such as canvas, cordura, and denim. It’s painted a gray/green hue almost as if to nestle into the machine shed alongside jerry cans and a howitzer.

C. Quilting and Patchwork:

This section will explore how heavy duty machines can handle quilting and patchwork projects, including tips for working with multiple layers and achieving precise stitching.

4. Cost-Effectiveness While the initial investment in an industrial overlocker may seem significant, the long-term savings in materials, time, and labor can make it a cost-effective solution. Fewer fabric defects result in lower material costs and a reduction in waste.

One of the key benefits of automatic button sewing machines is their precision. The machines come equipped with various settings that can be adjusted according to the size and type of button being used. This ensures that each button is securely attached to the fabric without the risk of damaging the garment. The accuracy of these machines also minimizes the likelihood of human error, which can lead to misaligned or poorly attached buttons that may need to be redone.

automatic button sewing machine

For those new to sewing or looking to streamline their process, the walking foot zigzag sewing machine offers ease of use. Setting up the machine with the walking foot is typically straightforward, and once in operation, it can significantly reduce the time spent on tedious tasks. The assurance that seams will be even and secure allows seamstresses to focus more on creativity and less on correction.

To get the most out of your handheld leather stitcher, consider these tips

Portability

The design of the CB2500 is not only aesthetically pleasing but also practical. Its lightweight structure makes it easy to transport, catering to those who attend sewing classes or need to move their machines frequently. Despite its portability, the CB2500 does not compromise on sturdiness. The machine's build quality ensures durability, providing years of reliable service.

cb2500 sewing machine