slurry pump body casing suppliers

Latest articles

If centrifugal, are the impellers of the right design and material?

slurry pump body casing suppliers...

slurry pump body casing suppliers 【slurry pump body casing suppliers】

Read MoreBetter safety

slurry pump body casing suppliers...

slurry pump body casing suppliers 【slurry pump body casing suppliers】

Read MoreSlurry pump seals

slurry pump body casing suppliers...

slurry pump body casing suppliers 【slurry pump body casing suppliers】

Read MoreSlurry pumps are usually larger than standard pumps, have more horsepower and use stronger bearings and shafts. The most common >type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids pass through a standard centrifugal pump.

slurry pump body casing suppliers...

slurry pump body casing suppliers 【slurry pump body casing suppliers】

Read MoreThe solution is to choose a >heavy duty slurry pump and, just as importantly, to use a custom built unit with replaceable parts. At Aier Machinery, building your custom slurry pump is one of our areas of expertise. We design your slurry pump to your specifications and application.

slurry pump body casing suppliers...

slurry pump body casing suppliers 【slurry pump body casing suppliers】

Read MoreSome models can generate discharge pressures up to 260 ft. (80 m).

slurry pump body casing suppliers...

slurry pump body casing suppliers 【slurry pump body casing suppliers】

Read MoreThe size of slurry pump impeller must be considered to ensure it holds up against abrasive wear. Slurry pump impellers are generally larger in size when compared to slurry pumps for less abrasive liquids. The more “meat” the impeller has, the better it will hold up to the task of pumping harsh slurry mixtures. Just think of slurry pump impeller as a football team’s offensive line. These players are usually large and slow. Throughout the whole game they are beaten up, over and over again, but expected to withstand the abuse. You wouldn’t want small players in this position, just like you wouldn’t want a small impeller on your slurry pumps.

slurry pump body casing suppliers...

slurry pump body casing suppliers 【slurry pump body casing suppliers】

Read MoreIf centrifugal, are the impellers of the right design and material?

slurry pump body casing suppliers...

slurry pump body casing suppliers 【slurry pump body casing suppliers】

Read MoreVertical Slurry Pump

slurry pump body casing suppliers...

slurry pump body casing suppliers 【slurry pump body casing suppliers】

Read MoreTypically, slurries are.

slurry pump body casing suppliers...

slurry pump body casing suppliers 【slurry pump body casing suppliers】

Read More

Popular articles

- Conveying medium

- Auxiliary equipment

- Centrifugal slurry pumps capable of providing high capacity with a limited head are mainly used for pumping slurry through pipes with a concentration of less than 70% by weight of solids. Centrifugal slurry pumps can be vertical, horizontal or submersible.

- >Slurry Pump

- Slurry Pump

- Many types of pumps are used for pumping slurries.The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a water-like liquid would move through a standard centrifugal pump.

Latest articles

-

With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

-

Customised pumps

-

Choosing The Right Slurry Pump For Your Application

-

The size and nature of the solids in the liquid: The size and nature will affect the amount of physical wear on the pump and its components, and whether the solids will pass through the pump without being damaged.

-

The Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

-

Mechanical Seals

Links

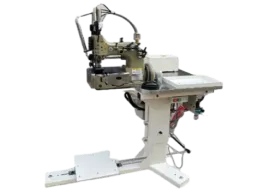

What is a Heavy Duty Basic Sewing Machine?

In the world of textile crafts, few machines have made as significant an impact as the zigzag sewing machine. Unlike traditional straight-stitch machines, the zigzag sewing machine offers a multitude of stitching options that can elevate a sewing project from ordinary to extraordinary. This article delves into the features, uses, and benefits of zigzag sewing machines, highlighting why they are an essential tool for both amateur and professional seamstresses.

3. Insert the Double Needle

The world of sewing machines is vast and varied, with each type designed for specific tasks to enhance efficiency and creativity in garment construction and textile creation. Among these specialized machines, the typical double needle sewing machine stands out as an essential tool for both amateur and professional sewists. This article delves into the features, benefits, and applications of dual-needle technology, providing insight into why it has become an indispensable instrument in the sewing industry.

industrial sewing machine needles for leather. The size of the needle refers to the diameter of the needle shaft, with larger numbers indicating thicker needles. For sewing leather, it is recommended to use needles with sizes ranging from 14 to 18, as these sizes are strong enough to penetrate through the material without causing damage.

One of the standout features of the lockstitch seam is its strength. The interlocking nature of the stitch creates solid seams that can withstand considerable strain, making them ideal for construction where durability is key, such as in sewing everyday clothing, bags, and upholstery. Additionally, the lockstitch lies flat against the fabric surface, which enhances the overall aesthetic appeal of the finished product.

4. Cost-Effective in the Long Run While the initial investment may be higher than a standard machine, the efficiency and durability of heavy-duty upholstery sewing machines can lead to cost savings over time. Frequent repairs on lesser machines can add up, making a high-quality machine a wise investment.

If you’re considering adding a zig zag industrial sewing machine to your shop or studio, there are several avenues you can explore. Local sewing and textile supply stores often carry industrial machines or can order them for you. Additionally, online marketplaces like eBay or Amazon frequently have listings for new and used machines.

When designing a spout rosette, several factors must be taken into account

If you want to add a professional touch to your sewing projects, learning how to use a twin needle on your sewing machine is essential. Twin needles allow you to create two parallel rows of stitches simultaneously, which not only enhances the aesthetic of your garments but also provides added durability. Here’s a comprehensive guide on how to effectively use a twin needle.

5. Sewing Supplies Thread, needles, and any additional embellishments (such as embroidery or decals) will bring your mats to life.

The PP bag silai machine is a transformative solution in the production of polypropylene bags, enhancing efficiency, quality, and sustainability. As industries increasingly shift towards eco-friendly practices, the demand for these machines is expected to rise. Investing in advanced sewing technology will not only improve manufacturing processes but also position businesses to meet the evolving needs of consumers and the environment. In summary, the PP bag silai machine stands at the forefront of industrial innovation, driving the future of packaging solutions.

Applications in the Textile Industry

Caring for items made with chain stitching requires special attention. Gently washing garments will help maintain their integrity. It is advisable to avoid harsh chemicals and high temperatures, which can degrade the thread and fabric over time.

Conclusion

The ease of use and time-saving capabilities of the automatic buttonhole sewing machine are invaluable, particularly for those handling large sewing projects. For small businesses and home-based seamstresses, the ability to quickly and accurately make buttonholes can significantly enhance productivity and contribute to a more efficient workflow. As a result, these machines have become increasingly popular among fashion designers and tailors looking to streamline their production processes.

The features and functionalities of the cylinder bed sewing machine also play a critical role in determining its price. Machines equipped with specialized attachments, automated features, or advanced control systems may come at a premium. For instance, a machine with an automatic needle positioning feature, thread trimmer, or programmable sewing patterns can cost significantly more than a basic model with manual controls.

cylinder bed sewing machine price

Do you have limited space for a sewing setup, or do you have a dedicated sewing room with ample workspace?

Ideal for Heavy Fabrics

double needle walking foot sewing machine

3. Janome HD3000 With its durable construction and user-friendly interface, the Janome HD3000 is a great option for those just starting in leather sewing. It provides easy stitch selection and a walking foot that aids in smooth feeding.

Another significant benefit is efficiency. With the ability to handle various fabric types and thicknesses, needle feed sewing machines streamline the production process, reducing the need for multiple machines and improving workflow in a manufacturing setting. This efficiency is especially crucial in today's fast-paced fashion landscape, where time-to-market is a critical factor for success.

3. Target User

auto sewing machine price

User-Friendly Features

4. Motor Power Industrial machines typically come with more powerful motors than domestic ones. A machine with a strong motor can handle heavy-duty sewing tasks without overheating or losing performance.

The Ultimate Guide to Heavy-Duty Sewing Machines for Thick Leather

In the realm of upholstery, the hand sewing machine is indispensable. Unlike its industrial counterparts, a hand sewing machine provides the precision and control necessary for intricate work. Upholsters often face unique challenges such as sewing through thick fabric layers, adjusting tension, and making detailed stitch patterns. Hand sewing machines are designed specifically for this purpose, enabling craftsmen to tackle a variety of materials—from delicate silk to heavy-duty canvas—while ensuring a professional finish.

Twin needle sewing has become an essential technique among sewing enthusiasts and professionals alike, serving various purposes that enhance both the aesthetic and functional quality of garments. This method utilizes two needles attached to a single shaft, allowing for two lines of stitching to be created simultaneously. It is particularly popular for finishing hems, creating decorative stitches, and adding a touch of elegance to knit fabrics.

One of the major advantages of a leather manual sewing machine is its cost-effectiveness. Unlike modern electric machines, which can be expensive and maintenance-intensive, manual machines are generally more affordable and durable, often lasting for decades with proper care. The simplicity of the mechanics also means there is less that can go wrong, giving artisans confidence in their tools.

2. Needle and Presser Feet Heavy-duty machines often come with specialized needles and presser feet designed specifically for leather. This will prevent skipping stitches and ensure clean, precise lines.

Key Features of Commercial Zig Zag Sewing Machines