high quality centrifugal vertical slurry pump factories

Latest articles

Types of slurry pump installation.

high quality centrifugal vertical slurry pump factories...

high quality centrifugal vertical slurry pump factories 【high quality centrifugal vertical slurry pump factories】

Read More- Installation flexibility - The submersible slurry pump is available in a variety of mounting models, including portable and semi-permanent (also easy to move as it can be freely suspended from a chain or similar device without having to be bolted to the ground/floor, etc.).

high quality centrifugal vertical slurry pump factories...

high quality centrifugal vertical slurry pump factories 【high quality centrifugal vertical slurry pump factories】

Read MoreA slurry is any mixture of a fluid (such as water) and a powdery solid. Slurries are used as a convenient way to handle bulk solids in the mining, steel processing, foundry, power generation and, more recently, frac sand mining industries. Slurries typically behave like viscous viscous fluids, flowing under gravity, but can also be pumped as needed.

high quality centrifugal vertical slurry pump factories...

high quality centrifugal vertical slurry pump factories 【high quality centrifugal vertical slurry pump factories】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

high quality centrifugal vertical slurry pump factories...

high quality centrifugal vertical slurry pump factories 【high quality centrifugal vertical slurry pump factories】

Read MoreWith the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

high quality centrifugal vertical slurry pump factories...

high quality centrifugal vertical slurry pump factories 【high quality centrifugal vertical slurry pump factories】

Read MoreSome models can generate discharge pressures up to 260 ft. (80 m).

high quality centrifugal vertical slurry pump factories...

high quality centrifugal vertical slurry pump factories 【high quality centrifugal vertical slurry pump factories】

Read MoreFirstly, analysing your duty helps us to determine whether you are using the type and size of pump best suited to your needs. Cavitation can occur due to surges; a very effective way to solve this problem is to install a choke on the pump head to increase the pressure on the casing, which then absorbs the surge, or to add a choke to the output to reduce the surge.

high quality centrifugal vertical slurry pump factories...

high quality centrifugal vertical slurry pump factories 【high quality centrifugal vertical slurry pump factories】

Read MoreIf youve ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. Theres no doubt that the slurry on the pump is hard. But the more you know about whats being pumped, the better your pump selection will be, resulting in longer mean time between failures.xa0Next, the , slurry pump supplier, will share the following content with you.

high quality centrifugal vertical slurry pump factories...

high quality centrifugal vertical slurry pump factories 【high quality centrifugal vertical slurry pump factories】

Read MoreTo reduce wear, reduce the pump discharge pressure to the lowest possible point.

high quality centrifugal vertical slurry pump factories...

high quality centrifugal vertical slurry pump factories 【high quality centrifugal vertical slurry pump factories】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

high quality centrifugal vertical slurry pump factories...

high quality centrifugal vertical slurry pump factories 【high quality centrifugal vertical slurry pump factories】

Read More

Popular articles

- Light-duty Slurry Pump

- Slurry Pump

- The rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

- Vertical Slurry Pumps Pump Sewage More Efficiently

- The concept of the >slurry pump and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

- When dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

Latest articles

-

A slurry is a mixture of fluids, which consists of a water-like liquid and particles. Typically, slurry acts in the same way as a viscous, sticky fluid - moving with gravity - but usually needs to be pumped.

-

If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

-

method and level of design reach international advanced level. The company has the first-class pump performance

-

Many types of pumps are used for pumping slurries.The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a water-like liquid would move through a standard centrifugal pump.

-

Magnetite mixing

-

>Dredge Pump

Links

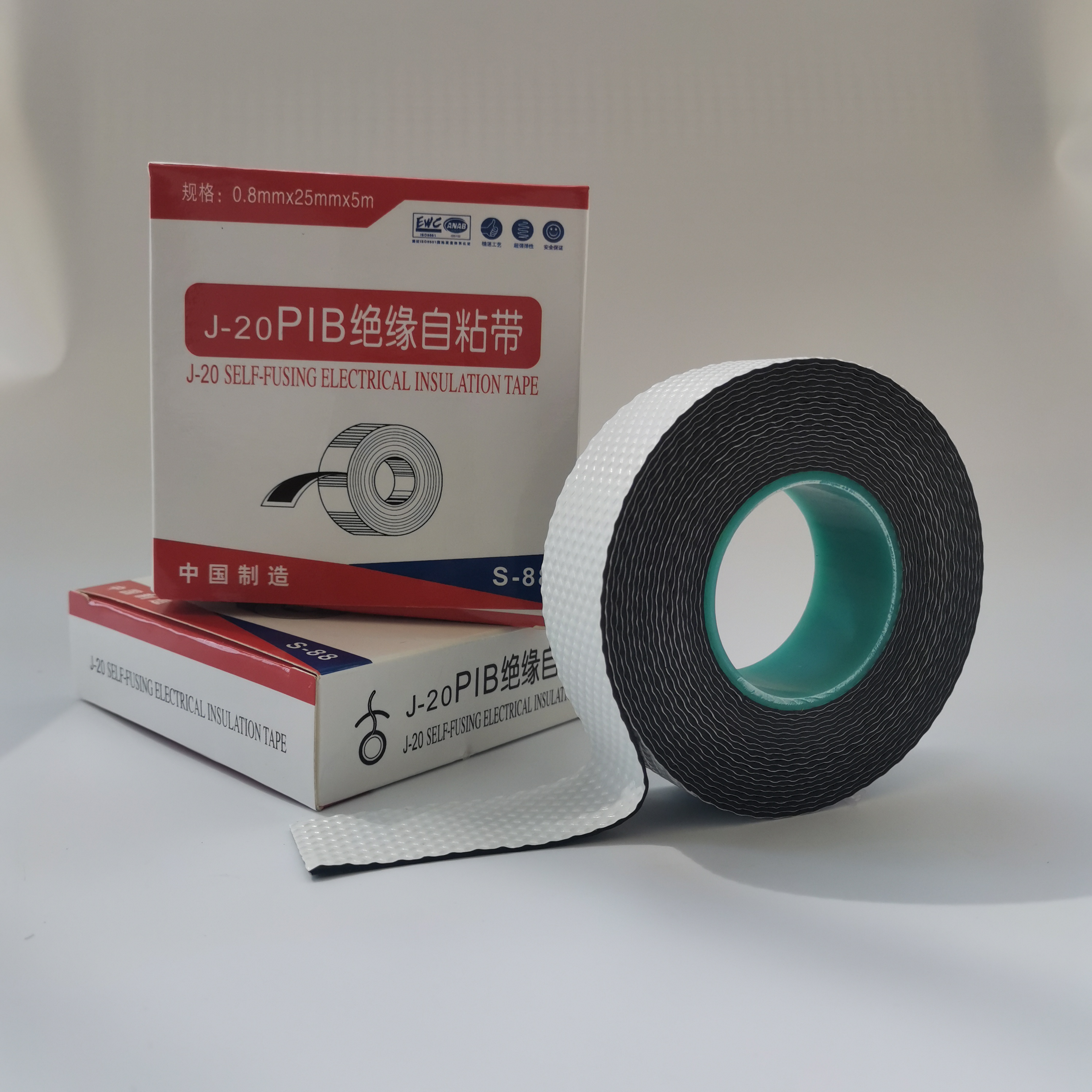

- The secret lies in its unique blend of flexibility and durability. Its thick, rubberized backing, combined with a powerful adhesive, allows it to conform seamlessly to any surface, creating an airtight, waterproof seal. The 4 x 5 size ensures that it can cover a substantial area while still being manageable and easy to apply. It's also resistant to extreme temperatures, making it suitable for use in both scorching heat and freezing cold.

In plumbing and automotive contexts, self-fusing tape serves as an effective tool for sealing leaks in hoses and pipes. Its ability to conform to different shapes ensures a tight seal, thereby preventing leaks from escalating into more significant issues.

- During emergencies, temporary floor markings can direct evacuation routes, pointing towards exits and safe zones. They can also indicate fire extinguishers, first aid kits, and other safety equipment, ensuring swift response in crisis situations. In healthcare facilities during the COVID-19 pandemic, this tape has been instrumental in implementing social distancing measures, marking out appropriate distances for queues and seating arrangements.

- Warehouse floor marking tape, an often overlooked yet indispensable tool in industrial settings, plays a pivotal role in maintaining order, enhancing safety, and boosting productivity within the warehouse environment. This humble strip of tape serves as a visual language that communicates crucial information to workers, equipment operators, and visitors, fostering a well-organized and secure workspace.

- Moreover, telecommunications companies utilize fire-resistant electrical tape to safeguard their cables and connections. Fiber optics and other sensitive cabling can be wrapped in this protective layer, ensuring that even under adverse conditions, data transmission remains uninterrupted and free from fire-related damage.

- The primary purpose of industrial floor marking tape is safety. It serves as a visual cue to guide workers, prevent accidents, and mark hazardous areas. For instance, yellow tapes are commonly used to indicate caution zones, while red marks danger areas. Green is used for safety equipment storage, blue for recyclable materials, and black and white stripes denote pedestrian walkways. This clear demarcation helps to minimize accidents and promote a safe working environment.

heat tape electric.

Motor lead insulation. In the case of low-voltage motor lead connections, the tape insulating process consists of connecting feeder cables to motor leads and arranging the conductors for easy wrapping. You should begin by wrapping two layers of varnished cambric tape, which is available with or without adhesive. For the adhesive type, apply with the adhesive side out for clean re-entry.

2. Automotive Use Car enthusiasts often keep Black Flex Tape in their repair kits. It can be used to fix things like windshield leaks, sealing gaps in the bodywork, or even temporarily repairing hoses and wires.

car door seal rubber strip.

. The material's density and resilience help to absorb and dampen noise, which can be particularly beneficial in urban areas or anywhere where external noise pollution is a concern. Buildings equipped with butyl rubber weather strips can enjoy a quieter interior environment, enhancing comfort and productivity.

. The material's density and resilience help to absorb and dampen noise, which can be particularly beneficial in urban areas or anywhere where external noise pollution is a concern. Buildings equipped with butyl rubber weather strips can enjoy a quieter interior environment, enhancing comfort and productivity. electrical pvc tape manufacturers. Marking The tapes can be used to mark wires, cables, and other components with information such as voltage levels, circuit numbers, and installation instructions.

electrical pvc tape manufacturers. Marking The tapes can be used to mark wires, cables, and other components with information such as voltage levels, circuit numbers, and installation instructions.Overall, Flex Tape Black is a versatile and reliable adhesive tape that can be used for a wide range of repairs and projects. Its waterproof, UV-resistant, and flexible properties make it a durable and long-lasting solution for a variety of needs. Whether you're fixing a leaky pipe, patching up a tear, or creating a custom project, Flex Tape Black is sure to help you get the job done.

pink flagging tape.

FOR YOUR CABLE MANAGEMENT CONSIDERATION

This makes it ideal for long-term use in both residential and commercial settings This makes it ideal for long-term use in both residential and commercial settings

This makes it ideal for long-term use in both residential and commercial settings This makes it ideal for long-term use in both residential and commercial settings fireproof tape.

fireproof tape.