hydraulic submersible slurry pump

Latest articles

The same point of slurry pump and mud pump

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreIt is often used if a short period of dry running is expected. Fluid is introduced into the area between the back of the seal face and the tight-fitting outlet on the drive side of the slurry pump.

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreStep 1

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreIncludes a large number of solids or particles.

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreAgain, to meet life cycle cost considerations, pumps should be equipped with large diameter impellers for lower operating speeds and longer wear life, as well as field replaceable rubber liners that can be bolted on for quick maintenance. In a typical coal-fired power plant, two to five pumps will be used in each spray tower.

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreMany types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read More>TL FGD Pump

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreTo reduce component wear, most centrifugal slurry pumps run at fairly low speeds - typically less than 1200 rpm. Find the optimum position that allows the pump to run as slowly as possible but fast enough to prevent solids from settling out of the slurry deposit and clogging the lines.

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreIf you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read MoreDredge Pump Features

hydraulic submersible slurry pump...

hydraulic submersible slurry pump 【hydraulic submersible slurry pump】

Read More

Popular articles

- Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High

- The company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

- >Slurry Pump vs Mud Pump

- - Low noise level - Operating underwater results in low noise or even silent operation.

- BCT Ceramic Slurry Pumps

- In dry installation, the hydraulic end and drive unit are located outside the oil sump. When using a submersible slurry pump for dry installation, the slurry pump must always have a cooling system installed. Consider the design of the water tank in order to deliver slurry to the pump. Agitators and side-mounted agitators cannot be used for this type of installation.

Latest articles

-

The concentration of solids in the slurry - measured as a percentage of the total volume.

-

The selection of a dredge or , slurry pump, can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

-

Depending on your own requirements, propeller seals, mechanical seals or packing seals can be used.

-

Some models can generate discharge pressures up to 260 ft. (80 m).

-

Slurry pumps are usually larger than standard pumps, have more horsepower and use stronger bearings and shafts. The most common >type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to the way aqueous liquids pass through a standard centrifugal pump.

-

Determine the nature of the material to be pumped

Links

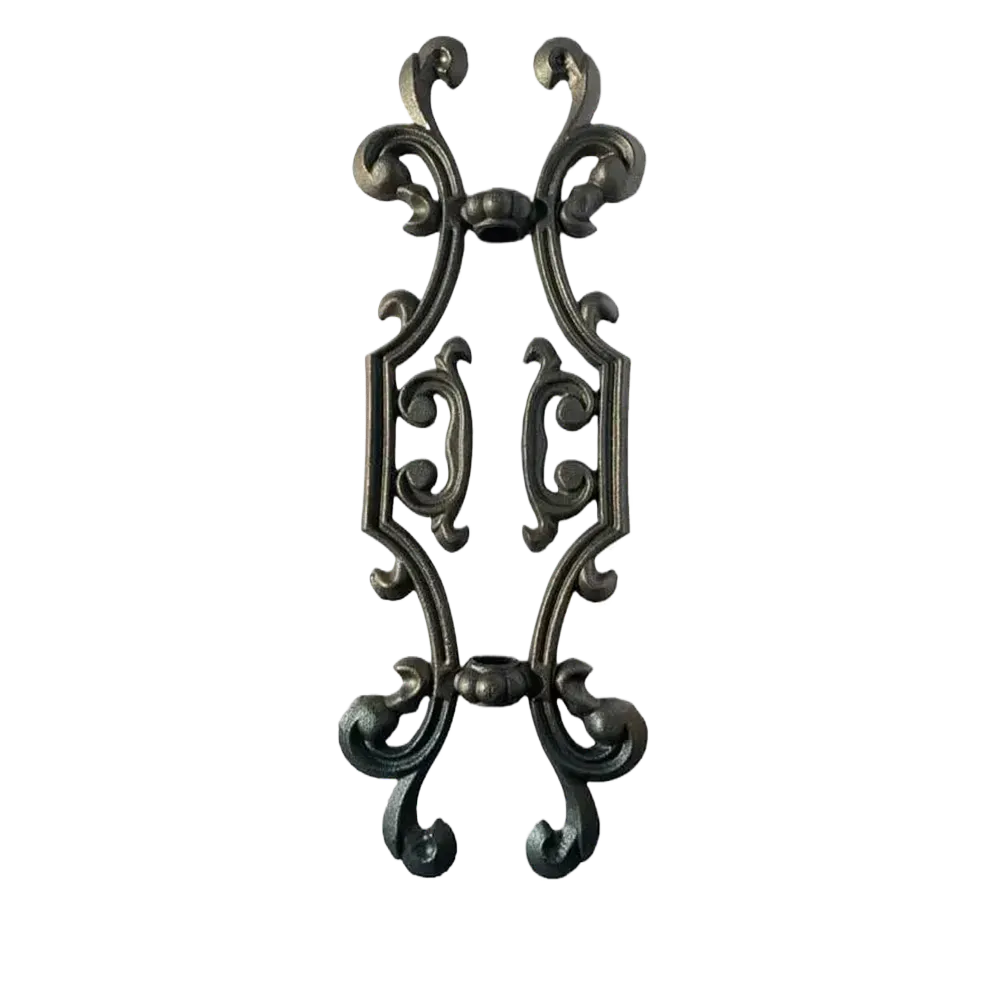

- Decorative fences made from ornamental iron are usually mass produced. Therefore, they have a more uniform look than their handcrafted counterparts.

Moreover, wrought iron ornaments can serve practical purposes beyond aesthetics. They can provide privacy, define property lines, or create secure enclosures for pets and children. With the right design, wrought iron can balance beauty and functionality seamlessly.

Wrought iron gate ornaments also carry significant cultural and historical symbolism. For instance, in many European countries, intricate wrought iron gates adorned with family crests or motifs often indicate the status and wealth of the homeowner. In the United States, particularly in the Southern states, wrought iron gates have become synonymous with elegance and grace, reminiscent of the grand estates of the past. The enduring popularity of these decorative elements highlights their ability to transcend time and trends.

wrought iron gate ornaments

For powder coating/anodizing/polishing: packaging+batten+steel

Environmental Impact and Sustainability Factors

2. Condensation Control In climates with variable temperatures, condensation can be a significant issue, leading to mold and deterioration of building materials. By reducing the temperature differentials on the interior surfaces, thermal break profiles help minimize the likelihood of condensation forming on windows and doors.

thermal break aluminium profile

l 3 powder coating lines.One verticals and two Horizontals.

They can be easily shaped and formed to create a wide range of designs, including traditional, modern, and contemporary styles They can be easily shaped and formed to create a wide range of designs, including traditional, modern, and contemporary styles

They can be easily shaped and formed to create a wide range of designs, including traditional, modern, and contemporary styles They can be easily shaped and formed to create a wide range of designs, including traditional, modern, and contemporary styles aluminium profiles for doors and windows. This versatility allows architects and designers to create unique and innovative door and window designs that stand out from the crowd.

aluminium profiles for doors and windows. This versatility allows architects and designers to create unique and innovative door and window designs that stand out from the crowd.Starting from the overall home decoration style, the color, size and style of windows and doors need to be considered. Buying a set of beautiful windows and doors with keeping styles with the whole house will not destroy the whole decoration effect. For example, the color of windows and doors should be close to the color of furniture, and the color of wall can maintain the contrast of correspondence. At the same time, the novelty and functionality of aluminium window and door can be customized, which can be used for reference standard to select good aluminium windows&doors.

A Brief Overview of Wrought Iron Fences

1. Top-Mount Rollers Positioned at the top of the door, these rollers guide the door as it slides open and closed. They help minimize door sagging and provide stable operation.

Furthermore, things can be a reflection of our personalities and values. The things we choose to surround ourselves with can be a form of self-expression. For example, someone who values creativity and individuality may decorate their home with unique artwork and handmade crafts. On the other hand, someone who values simplicity and minimalism may prefer a more streamlined and clutter-free living space. Our things can be a physical manifestation of who we are and what we believe in.

Wrought iron is generally longer-lasting than cast iron. As we said, cast iron is harder but it’s also more brittle. The extra carbon in its molecular structure compared with wrought iron results in internal stress points that are more likely to fracture under extreme stress rather than bend. There are advantages and disadvantages to this: cast iron is more likely to retain its exact shape without undergoing any warping or bending.

Steel is created after the addition and subtraction of several natural and man-made compounds.

Pear Wool + Heat Shrink Film