china limestone slurry pump factories

Latest articles

Conveying medium

china limestone slurry pump factories...

china limestone slurry pump factories 【china limestone slurry pump factories】

Read MoreSlurry Pump Impeller Type

china limestone slurry pump factories...

china limestone slurry pump factories 【china limestone slurry pump factories】

Read MoreStainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

china limestone slurry pump factories...

china limestone slurry pump factories 【china limestone slurry pump factories】

Read MoreVertical Slurry Pump

china limestone slurry pump factories...

china limestone slurry pump factories 【china limestone slurry pump factories】

Read MoreMetal and/or rubber pump bushings are used to combat the erosion of solid particles found in the slurry. Metal slurry pump housings are usually made of carbide to resist erosion caused by increased pressure and circulation. Sometimes wear-resistant steel is used on the pump casing so that the pump can be welded if repairs are needed.

china limestone slurry pump factories...

china limestone slurry pump factories 【china limestone slurry pump factories】

Read MoreBCT Ceramic Slurry Pumps

china limestone slurry pump factories...

china limestone slurry pump factories 【china limestone slurry pump factories】

Read MoreThe same point of slurry pump and mud pump

china limestone slurry pump factories...

china limestone slurry pump factories 【china limestone slurry pump factories】

Read MoreHow to choose a slurry pump?

china limestone slurry pump factories...

china limestone slurry pump factories 【china limestone slurry pump factories】

Read MoreAs described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

china limestone slurry pump factories...

china limestone slurry pump factories 【china limestone slurry pump factories】

Read MoreMagnetite mixing

china limestone slurry pump factories...

china limestone slurry pump factories 【china limestone slurry pump factories】

Read More

Popular articles

- Consider the impeller. Slurry pumps must have thicker vanes than water pumps to prevent wear. Due to the increased thickness, there will be fewer vanes, otherwise the passages will be too narrow and will affect the performance of the pump. The impeller should have a large enough passage so that the largest solid particles can pass through without clogging.

- When pumping slurry in wet sand applications, we must evaluate the abrasive particles flowing through the piping and then assess how they affect the slurry pump. If the pump is lined with poor quality rubber, the particles will not rebound effectively and, as a result, the rubber will begin to break down. The air shavings then begin to accelerate and negatively impact the efficiency of the pump, often leading to turbulence.

- On the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

- >Slurry Pump

- What is a slurry pump?

- WZ series slurry pumps are developed on the wide adaption of both home and abroad advance technology and many years of slurry pump design and field operation experiences.

Latest articles

-

Dredge Pump

-

Aier is pumping experts and offer some useful tips to maintain your >slurry pump.

-

When flushing is required, the >slurry pump supplier recommends the API Option 32 sealed pipe arrangement as it is more suitable for services containing solids or contaminants that could damage the seal faces if recirculated in the flushing medium.

-

If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

-

Working principle

-

Pumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal target=_blank title=Slurry Pump>slurry pump. Let's talk about how slurry pumps differ from standard pumps and how to narrow your choices.

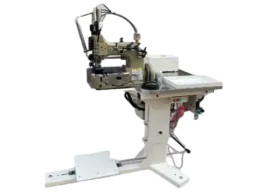

The Importance of Bag Closer Machine Parts in Modern Packaging