high quality best pump for lime slurry

Latest articles

Hydrostatic head - i.e. the height to which the slurry must be lifted in the piping system.

high quality best pump for lime slurry...

high quality best pump for lime slurry 【high quality best pump for lime slurry】

Read MoreLarger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

high quality best pump for lime slurry...

high quality best pump for lime slurry 【high quality best pump for lime slurry】

Read MoreSlurry Pump

high quality best pump for lime slurry...

high quality best pump for lime slurry 【high quality best pump for lime slurry】

Read MoreWith the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

high quality best pump for lime slurry...

high quality best pump for lime slurry 【high quality best pump for lime slurry】

Read MorePumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal target=_blank title=Slurry Pump>slurry pump. Let's talk about how slurry pumps differ from standard pumps and how to narrow your choices.

high quality best pump for lime slurry...

high quality best pump for lime slurry 【high quality best pump for lime slurry】

Read MoreAll products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

high quality best pump for lime slurry...

high quality best pump for lime slurry 【high quality best pump for lime slurry】

Read MoreWill solids size pass through the pump?

high quality best pump for lime slurry...

high quality best pump for lime slurry 【high quality best pump for lime slurry】

Read MoreAll manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

high quality best pump for lime slurry...

high quality best pump for lime slurry 【high quality best pump for lime slurry】

Read MoreSlurry pumps can be used to transport mixtures of liquids and solids in many industries in a wide range of applications, such as mine drainage, dredging of sunken lagoons and pumping of drilling mud.

high quality best pump for lime slurry...

high quality best pump for lime slurry 【high quality best pump for lime slurry】

Read MoreSlurry Pump

high quality best pump for lime slurry...

high quality best pump for lime slurry 【high quality best pump for lime slurry】

Read More

Popular articles

- Slurry Pump Speed

- The basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

- For example.

- Slurry Pump Impeller Size

- Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

- It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

Latest articles

-

These conditions include

-

If you want to know more information about the best dredge pump, welcome to >contact us today or request a quote.

-

When the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

-

Fewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

-

Safety

-

Mechanical Seals

Links

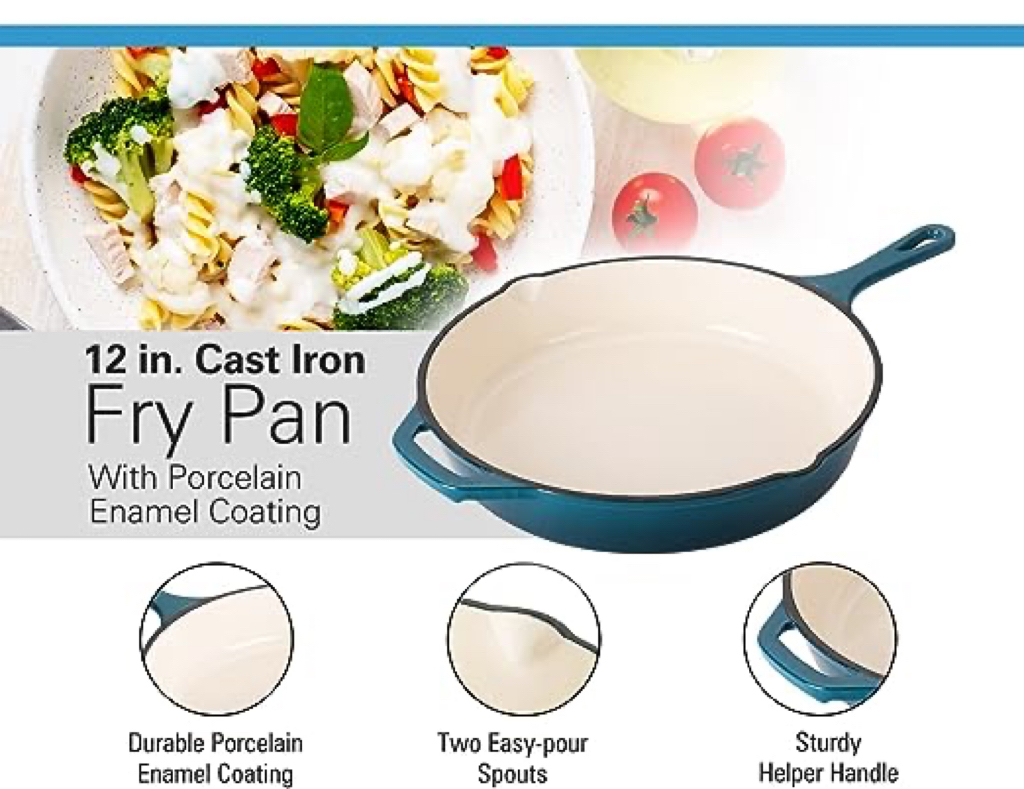

Frying Pan Sizes

- In conclusion, cleaning a lodge grill pan may require a little more effort than a typical non-stick pan, but the result is worth it. The unique smoky flavor and durability it offers make it a favorite among many home cooks and professional chefs. So, the next time you fire up your lodge grill pan, remember that a little extra effort in cleaning will go a long way in preserving its quality and performance.

- One of the main benefits of using a bacon press is that it helps to prevent bacon from curling as it cooks. When bacon curls up in the pan, it can cook unevenly and may not be as crispy as desired. By using a bacon press, the weight of the press helps to keep the bacon flat and in constant contact with the heat source, resulting in evenly cooked strips of bacon.

Dutch ovens are versatile and durable cooking vessels that have been used for centuries. They are known for their ability to retain and distribute heat evenly, making them suitable for a wide range of cooking methods. Here, we will explore the types, materials, and uses of Dutch ovens.

- In conclusion, porcelain-coated cast iron cookware sets are a valuable investment for any kitchen. They offer a harmonious blend of performance, durability, and style, making them suitable for everyday cooking and special occasions. With proper care, they can last for generations, testament to their enduring quality and timeless appeal.

- One of the key benefits of non-stick enamel cookware is its versatility. It can be used on various heat sources, including gas, electric, ceramic, and even induction stovetops, making it adaptable to different kitchen setups. Moreover, many non-stick enamel pieces are oven-safe, allowing for seamless transitions from stove to oven, perfect for dishes that require braising or roasting.

Professional Kitchens: In professional kitchens, black cast iron griddles and grill pans are essential tools for achieving consistent and high-quality results. They are used for searing steaks, grilling vegetables, and creating signature dishes with distinctive grill marks.

The frying pan is undoubtedly cookware that you use daily. It is adaptable and can do varied cooking that no other equipment can.

It's also resistant to chipping, cracking, and rust, ensuring long-lasting performance It's also resistant to chipping, cracking, and rust, ensuring long-lasting performance

It's also resistant to chipping, cracking, and rust, ensuring long-lasting performance It's also resistant to chipping, cracking, and rust, ensuring long-lasting performance kitchen aid cast iron grill pan. Moreover, the cast iron material makes it compatible with all stovetops, including induction, oven, broiler, and even campfire, offering unparalleled versatility.

kitchen aid cast iron grill pan. Moreover, the cast iron material makes it compatible with all stovetops, including induction, oven, broiler, and even campfire, offering unparalleled versatility.Cast iron cookware has been a staple in the kitchen for centuries, and for good reason. Its durability, versatility, and ability to retain and evenly distribute heat make Cast iron cookware a popular choice for home cooks and professional chefs alike. From enameled pots and Dutch ovens to griddles, skillets, and griddles, there are various types of cast iron cookware to suit different cooking needs.

It's not uncommon to see a well-seasoned skillet passed down through generations as a family heirloom It's not uncommon to see a well-seasoned skillet passed down through generations as a family heirloom

It's not uncommon to see a well-seasoned skillet passed down through generations as a family heirloom It's not uncommon to see a well-seasoned skillet passed down through generations as a family heirloom big cast iron skillet.

big cast iron skillet. crock pot enameled cast iron set. It's resistant to chipping, cracking, and staining, ensuring that your cookware retains its pristine appearance even after years of use. Moreover, the enamel surface is dishwasher safe, simplifying the cleaning process.

crock pot enameled cast iron set. It's resistant to chipping, cracking, and staining, ensuring that your cookware retains its pristine appearance even after years of use. Moreover, the enamel surface is dishwasher safe, simplifying the cleaning process.Additionally, the versatility of cast iron skillets extends to outdoor cooking. Whether you're grilling on the grill or cooking over an open flame while camping, this versatile cast iron skillets can handle high temperatures and deliver consistent cooking results. Cast Iron Skillet sturdy construction and insulating properties make it a solid choice for outdoor cooking adventures, ensuring you can enjoy delicious meals even away from the comfort of your kitchen.

Ready to Shop?

The flat surface also makes it easier to manage multiple dishes simultaneously, making it perfect for family gatherings or backyard barbecues The flat surface also makes it easier to manage multiple dishes simultaneously, making it perfect for family gatherings or backyard barbecues

The flat surface also makes it easier to manage multiple dishes simultaneously, making it perfect for family gatherings or backyard barbecues The flat surface also makes it easier to manage multiple dishes simultaneously, making it perfect for family gatherings or backyard barbecues cast iron flat top gas grill.

cast iron flat top gas grill.How to Clean Stainless Steel Pans

Bare cast iron frying pans are uncoated and therefore prone to rust. To prevent this, they can be seasoned with oil, which closes up the pores and prevents contact with water. After seasoning, cast iron pans don't need to be washed with soap and water after every use. Simply wipe the pan down with a pot. If the pan is very dirty, it can be washed but it will have to be re-seasoned.

While it is also rare for skillets to come with a lid, you’ll certainly see it more often than you would on a frypan. The lid is also typically fully opaque so you won’t be able to monitor your cooking as easily. But it sure helps with slow-cooking and braising dishes.

Advantages:

Cast Iron Meat Press

The griddle's large surface area also allows you to cook multiple dishes at once, making it perfect for entertaining or feeding a large group of people The griddle's large surface area also allows you to cook multiple dishes at once, making it perfect for entertaining or feeding a large group of people

The griddle's large surface area also allows you to cook multiple dishes at once, making it perfect for entertaining or feeding a large group of people The griddle's large surface area also allows you to cook multiple dishes at once, making it perfect for entertaining or feeding a large group of people flat cast iron griddle for grill.

flat cast iron griddle for grill. This adaptability makes them perfect for outdoor adventures, from backyard barbecues to camping trips This adaptability makes them perfect for outdoor adventures, from backyard barbecues to camping trips

This adaptability makes them perfect for outdoor adventures, from backyard barbecues to camping trips This adaptability makes them perfect for outdoor adventures, from backyard barbecues to camping trips cast iron bbq grill plate.

cast iron bbq grill plate.Proper use and storage of enamel cookware is also key to maintaining its quality. Avoid air-firing enamel pot at high temperatures to avoid damaging the enamel surface. When storing enamel cast iron pots for sale, it’s a good idea to wrap it in a soft cloth or paper towel to prevent scratches or bumps.

A frying pan can be made of a variety of high-quality metalcore materials. It was originally constructed from heavy cast iron, which is incredibly solid and durable.

cast iron egg skillet. Their classic black finish and rustic charm add a touch of elegance to your cooking space. Whether you display them hanging on a pot rack or store them in a cabinet, cast iron skillets are sure to impress your guests and elevate your cooking experience.