limestone slurry pump manufacturer

Latest articles

It is often used if a short period of dry running is expected. Fluid is introduced into the area between the back of the seal face and the tight-fitting outlet on the drive side of the slurry pump.

limestone slurry pump manufacturer...

limestone slurry pump manufacturer 【limestone slurry pump manufacturer】

Read MoreThere is a better way to pump sewage, overflows and other collected dirty water around the plant.

limestone slurry pump manufacturer...

limestone slurry pump manufacturer 【limestone slurry pump manufacturer】

Read MoreAuxiliary equipment

limestone slurry pump manufacturer...

limestone slurry pump manufacturer 【limestone slurry pump manufacturer】

Read MoreThe winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

limestone slurry pump manufacturer...

limestone slurry pump manufacturer 【limestone slurry pump manufacturer】

Read MoreWhat is the pump constructed of?

limestone slurry pump manufacturer...

limestone slurry pump manufacturer 【limestone slurry pump manufacturer】

Read MoreA dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

limestone slurry pump manufacturer...

limestone slurry pump manufacturer 【limestone slurry pump manufacturer】

Read MoreSlurry Pump

limestone slurry pump manufacturer...

limestone slurry pump manufacturer 【limestone slurry pump manufacturer】

Read MoreThe Difference Between Flushing And Quenching in Slurry Pump Seals

limestone slurry pump manufacturer...

limestone slurry pump manufacturer 【limestone slurry pump manufacturer】

Read MoreThe company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

limestone slurry pump manufacturer...

limestone slurry pump manufacturer 【limestone slurry pump manufacturer】

Read MoreWhat we mean by slurry is basically a liquid containing solid particles. When you want to pump this slurry, there are different requirements than when pumping only dirty water. A waste water pump cannot handle the solid particles of a slurry. This is where slurry pumps come in handy. >Slurry pumps are heavy duty and robust versions of centrifugal pumps, capable of handling tough and abrasive tasks.

limestone slurry pump manufacturer...

limestone slurry pump manufacturer 【limestone slurry pump manufacturer】

Read More

Popular articles

- - Keeping clean catch basins clean from solids

- All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

- When dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

- The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

- Light-duty Slurry Pump

- Determine the nature of the material to be pumped

Latest articles

-

Process speed doesn’t have anything to do with choosing slurry pump impeller, but it does have an effect on the life of slurry pump impeller. It is important to find the sweet spot that allows the slurry pump to run as slow as possible, but fast enough to keep solids from settling and clogging. If pumping too fast, the slurry can quickly erode the impeller due to its abrasive nature. This is why it is important to select a larger impeller if possible.

-

Magnetite mixing

-

Choosing the Right Pump for Flue Gas Desulphurisation

-

Slurry pump construction materials

-

The slurry pump is mainly used in the mining industry, its wear resistance is strong. So It conveys slurry that containing slag, but it can conveys mud. The mud pump is usually made of cast iron, the wear resistance of the pump is low. So the mud pumps often used for conveying mud or slurry containing suspended particles.

-

Slurry Pump

Links

- Beyond these sectors, vulcanizing tape is also finding novel applications in fields such as aerospace, marine, and renewable energy. Its unique properties allow it to withstand the rigors of these environments, making it an essential component in the development of advanced technologies.

Electrical tape is designed to adhere to wires, its tolerance for higher temperatures is a bit more resilient when compared to duct tape. Duct tape loses its stickiness and adhesive strength when exposed to high temperatures for a long time. If left long enough, the fibers duct tape uses for strength would eventually catch fire.

- The Flex Tape Gray A Versatile and Essential Tool for Every DIY Enthusiast

- Furthermore, in manufacturing plants, the tape is employed to seal and protect pipes, valves, and fittings exposed to high temperatures, ensuring smooth operations and preventing leaks or damage.

- 4. Seal the seams Once you have applied the entire length of tape, use a damp cloth to smooth out any remaining wrinkles or bubbles. Then, apply a thin layer of joint compound over the tape, feathering it out so that it blends seamlessly with the surrounding drywall. Allow the compound to dry completely before sanding it smooth.

- Plasma spray & thermal spray

- In conclusion, the price of rubber tape is an important consideration when shopping for this essential tool. By weighing factors such as quality, quantity, and intended use, you can make an informed decision and select the best rubber tape for your needs at a price that fits your budget.

Q: Can I use 3M Rubber Electrical Tapes for all types of wires?

This black sealing & insulating tape is our most economical option in our self-fusing tape family. It's a popular choice for everyone from electricians and plumbers through to DIYers.

- Rubber flex tape, a versatile and essential product, has been widely used in various industries for its outstanding properties. This tape, made from high-quality rubber, is known for its flexibility, durability, and resistance to extreme temperatures. It is an ideal solution for a wide range of applications, making it an indispensable tool for professionals and homeowners alike.

- 1

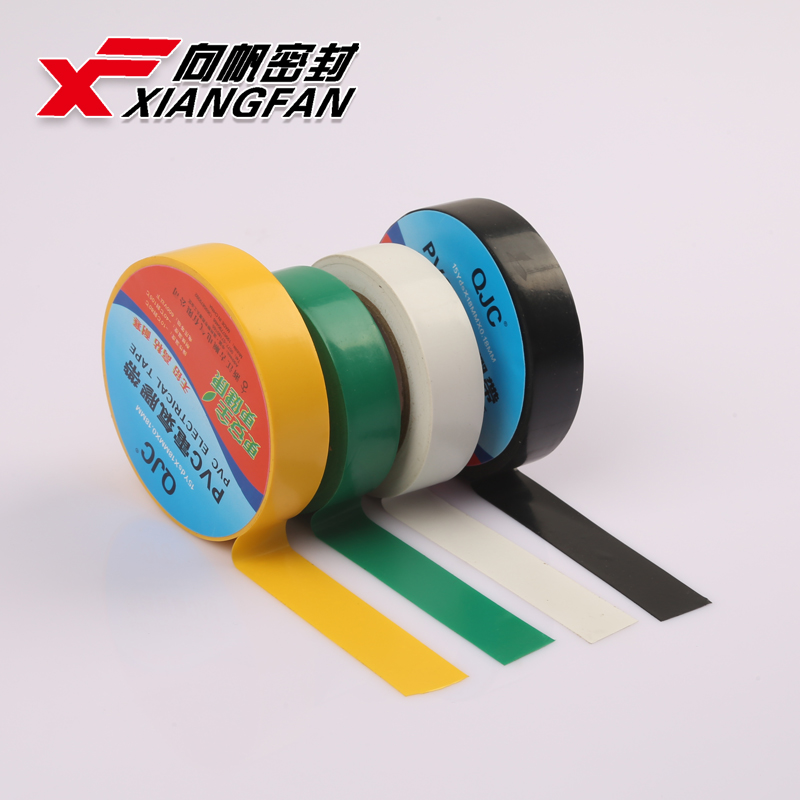

- One of the primary functions of PVC insulation electrical tape is to provide insulation to electrical conductors. It prevents the flow of electricity through unintended paths, reducing the risk of short circuits and electric shocks. The tape's dielectric strength, or its ability to resist the flow of electric current, is a key factor in its effectiveness as an insulator.

- Polyethylene Tape is used for wrapping and protecting pipes to prevent corrosion and provide insulation. It forms a barrier against moisture, chemicals, and other corrosive substances, making it ideal for applications in plumbing, oil and gas industries, or underground pipelines.

In addition to its thermal resistance, silicone insulation tape is highly flexible. This characteristic allows it to conform to irregular surfaces, ensuring comprehensive coverage and effective insulation. Whether wrapping electrical wires, reinforcing connections, or protecting sensitive components, silicone tape adheres securely without the need for additional adhesives. Its self-fusing properties enable it to bond to itself when wrapped, creating a durable and robust protective layer that can withstand vibration and movement.

- In conclusion, automotive wiring harness tape is more than just a simple adhesive strip; it is a vital element in the safe and efficient operation of a vehicle. Its role in protecting the wiring system, enhancing safety, and facilitating maintenance cannot be overstated. As the automotive industry continues to evolve, so too will the technology and materials behind this seemingly humble yet indispensable component.

Anderson points out that repair situations can arise in the field where a splicer does not have access to a particular kit for the job. However, knowing how to make proper use of tape can save the day, getting the customer back online quickly. “It's far more economical to complete a job on the spot with tape than to go in search of a kit,” Anderson maintains.

The short answer is no, but the long answer is a bit more complicated.

Many users rave about the ease of use that Flex Tape offers. The 4x5 size is manageable, making it convenient to apply even in tight spaces. Unlike traditional adhesives, which often require additional tools or curing time, Flex Tape can be cut to size, applied directly, and manipulated immediately. This feature is particularly advantageous for those who may not have extensive experience with repairs, allowing anyone to tackle minor issues with confidence.

Tape adhesive types: Silicone vs. Acrylic vs. Rubber

Modified acrylic

As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems

As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems As a result, rubber splicing tape became an essential component in the production of electrical cables, hoses, and other flexible systems 23 rubber splicing tape.

23 rubber splicing tape. butyl rubber tape suppliers. While it's important to find a supplier who offers competitive prices, you should also ensure that you're not sacrificing quality for cost. Look for suppliers who offer a range of pricing options to suit your budget, and be wary of suppliers who offer extremely low prices, as this may indicate that they're cutting corners on quality.

butyl rubber tape suppliers. While it's important to find a supplier who offers competitive prices, you should also ensure that you're not sacrificing quality for cost. Look for suppliers who offer a range of pricing options to suit your budget, and be wary of suppliers who offer extremely low prices, as this may indicate that they're cutting corners on quality.1. Dielectric Strength High voltage insulation tape must possess excellent dielectric properties to withstand high electric fields without breaking down. The dielectric strength is a measure of the tape's ability to insulate against electrical current.

yellow warehouse floor tape. Unlike paint, which can be messy and time-consuming to apply, tape can be easily installed and removed as needed. This makes it a flexible option for businesses that may need to modify their floor markings frequently.