high quality slurry warman pump drawings manufacturer

Latest articles

Some models can generate discharge pressures up to 260 ft. (80 m).

high quality slurry warman pump drawings manufacturer...

high quality slurry warman pump drawings manufacturer 【high quality slurry warman pump drawings manufacturer】

Read More- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

high quality slurry warman pump drawings manufacturer...

high quality slurry warman pump drawings manufacturer 【high quality slurry warman pump drawings manufacturer】

Read Moretesting station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

high quality slurry warman pump drawings manufacturer...

high quality slurry warman pump drawings manufacturer 【high quality slurry warman pump drawings manufacturer】

Read MoreMany types of pumps are used for pumping slurries.The centrifugal slurry pump uses the centrifugal force generated by a rotating impeller to impact kinetic energy to the slurry, similar to how a water-like liquid would move through a standard centrifugal pump.

high quality slurry warman pump drawings manufacturer...

high quality slurry warman pump drawings manufacturer 【high quality slurry warman pump drawings manufacturer】

Read MoreSubmersible Slurry Pump

high quality slurry warman pump drawings manufacturer...

high quality slurry warman pump drawings manufacturer 【high quality slurry warman pump drawings manufacturer】

Read MoreReduced inventory

high quality slurry warman pump drawings manufacturer...

high quality slurry warman pump drawings manufacturer 【high quality slurry warman pump drawings manufacturer】

Read More- Pumping the final product in a process

high quality slurry warman pump drawings manufacturer...

high quality slurry warman pump drawings manufacturer 【high quality slurry warman pump drawings manufacturer】

Read MoreCorrosiveness of the slurry

high quality slurry warman pump drawings manufacturer...

high quality slurry warman pump drawings manufacturer 【high quality slurry warman pump drawings manufacturer】

Read MoreExamples of these dubious enhancements to impeller adjustment abound in the industry. One of these is the adjustable wear ring or suction liner to maintain the recommended clearance between the impeller front shroud and the throat bushing face. Almost all >slurry pumps, including AIER® slurry pumps, have features to ensure that this equipment specification can be maintained over time.

high quality slurry warman pump drawings manufacturer...

high quality slurry warman pump drawings manufacturer 【high quality slurry warman pump drawings manufacturer】

Read MoreThe company uses advanced computer assistant engineering software to design products and technology, which makes our method and level of design reach international advanced level. The company has the first-class pump performance testing station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000 sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

high quality slurry warman pump drawings manufacturer...

high quality slurry warman pump drawings manufacturer 【high quality slurry warman pump drawings manufacturer】

Read More

Popular articles

- Many types of pumps are used to pump slurry, but the most common slurry pump is the centrifugal pump. Centrifugal slurry pumps use centrifugal force from a rotating impeller to impinge kinetic energy on the slurry, similar to the way watery liquids pass through a standard centrifugal pump.

- As wear is a function of speed, slurry pumps should be operated at the lowest possible speed; units typically run at 1,200 rpm or less. Often, direct coupling between the pump and a low-speed motor or other drive makes the most sense. On the other hand, many other applications favour gearboxes to meet the required speed and operating point. In services where variable flow rates are required, variable frequency drives are used to provide the necessary continuous speed variation.

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- How does a dredge pump work?

- Choosing Dry Slurry Pumps Versus Submersible Slurry Pumps

- Mud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

Latest articles

-

Larger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

-

Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

-

Dredge pumps are designed to transfer large quantities of fluids and solids.

-

Two types of slurry are found in these industries.

-

What is the pump constructed of?

-

Ideal for slurry pumps - Only rubber lined pumps combine strength and corrosion resistance to create a quality slurry pump.

Links

Adicionalmente, la ubicación geográfica de la compra puede influir en el costo total. Los precios pueden variar entre regiones debido a costos de transporte y disponibilidad de proveedores locales. Las empresas deben considerar estos factores al realizar sus adquisiciones.

Elliptical Motion Screens: Elliptical motion screens combine linear and circular vibration patterns, offering versatility and efficient separation for various materials.

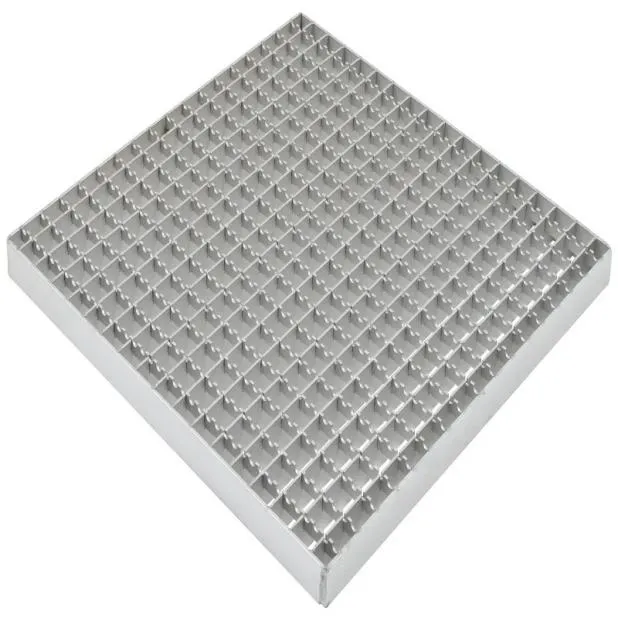

Heavy duty steel grating er en nøglekomponent i mange industrielle applikationer, hvor styrke, holdbarhed og sikkerhed er af højeste prioritet. Dette speciale gittermateriale er designet til at bære betydelige belastninger og er ideelt til brug i miljøer, hvor der er behov for ekstra modstand mod slid og mekanisk påvirkning.

Le Grillage de Sol Une Solution Pratique et Esthétique

Stahlgitterroste sind eine praktische und vielseitige Lösung für viele Bau- und Ingenieuranwendungen. Die verfügbaren Größen und Typen ermöglichen es, für jede Anforderung die richtige Lösung zu finden. Ob in der Industrie oder im öffentlichen Raum, Stahlgitterroste bieten Sicherheit, Haltbarkeit und Funktionalität.

In conclusion, heavy-duty steel grating is a reliable and versatile solution for industrial flooring needs. Its strength, slip resistance, ease of maintenance, and customizable options make it a preferred choice across various sectors. By investing in high-quality steel grating, businesses can enhance safety, efficiency, and sustainability in their operations.

Podsumowując, ekrany węglanowe są nie tylko technologiczną innowacją, ale również niezbędnym elementem zrównoważonego rozwoju przemysłu naftowego i gazowego. Ich funkcjonalność i zalety sprawiają, że stają się one kluczowym narzędziem w dążeniu do zwiększenia efektywności i minimalizacji wpływu na środowisko. W miarę postępu technicznego i rosnącej konkurencji, ich zastosowanie będzie przybywać, co niewątpliwie wpłynie na przyszłość sektora energetycznego.

- Durability Steel grating is resistant to corrosion and can withstand extreme environmental conditions, making it a long-lasting choice for various industries.

Environmental protection: In some applications, shaker screens are used to remove contaminants from industrial waste streams. This helps to protect the environment and comply with regulatory requirements. By preventing the release of solid particles into the environment, shaker screens contribute to sustainable drilling practices.

Onderhoud

갈바나이즈드 금속 그레이트의 가장 큰 장점 중 하나는 뛰어난 내구성입니다. 아연 코팅은 그레이트가 외부 환경, 특히 습기와 같은 요소로부터 보호해 줍니다. 이로 인해 재료는 오랜 기간 동안 고유의 형태와 기능을 유지할 수 있습니다. 이는 건축물이나 산업 시설에서 긴 수명을 보장하며, 유지보수 비용을 절감하는 데 큰 도움이 됩니다.

Sammanfattningsvis är hot-dip galvaniserad gitter en mångsidig och hållbar lösning för olika industrisektorer. Dess korrosionsskyddande egenskaper, långvariga prestanda och estetiska fördelar gör det till ett attraktivt val för både konstruktions- och designprojekt. Genom att välja denna typ av gitter kan företag inte bara förbättra sin effektivitet utan också bidra till en mer hållbar framtid.

スチールグレーチングのサイズ選びは、単なる寸法だけではなく、使用環境や目的に応じた幅広い考慮が必要です。適切なサイズと仕様を選ぶことで、安全で効率的な使用が可能になります。

環境面でもアルミニウムは優れています。リサイクルが容易であり、再利用率は非常に高いです。このため、環境負荷を低減し、持続可能な社会の構築に貢献しています。また、アルミニウム製品はその寿命が長く、長期的に見ればコストの面でも非常に経済的です。

One of the principal benefits of galvanised steel grating is its outstanding resistance to rust and corrosion. This quality makes it particularly valuable in environments exposed to moisture, chemicals, or extreme weather conditions. Industries such as waste management, water treatment, and chemical processing frequently rely on galvanised steel grating due to its long-lasting performance and minimal maintenance requirements.

Ein weiterer Vorteil ist die Vielseitigkeit. Rinneneinlaufschächte können in verschiedenen Größen und Designs hergestellt werden, um sich an unterschiedliche Umgebungen und Anforderungen anzupassen. Sie sind in Gewerbegebieten, Wohnsiedlungen, Sportanlagen und öffentlichen Plätzen zu finden. Diese Flexibilität ermöglicht es Architekten, innovative Lösungen zu entwickeln, die sowohl funktional als auch ästhetisch sind.

Podsumowując, zakup stalowych kratownic wymaga przemyślenia wielu aspektów, od ich przeznaczenia, przez wybór dostawcy, po koszty. Dokładne zbadanie dostępnych opcji oraz skonsultowanie się z fachowcami z branży pozwoli na podjęcie najlepszej decyzji, co z pewnością zaowocuje zadowoleniem z zakupu i długotrwałym użytkowaniem produktów.