high quality warman slurry pump spares manufacturer

Latest articles

Slurry pump seals

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreDefinition of dredge and slurry pumps

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreStainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreThe concentration of solids in the slurry - measured as a percentage of the total volume.

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreDetermine the operating parameters of the pump.

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreA variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreSlurry Pump Considerations

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreSlurry Pump

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreWhat style of pump is suitable?

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read More

Popular articles

- The winch dredger is usually equipped with a hull-mounted dredge pump, which has an impeller centered at or below the draft line for further production and improved suction efficiency.

- 2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

- Auxiliary equipment

- Slurry pumps can be used to transport mixtures of liquids and solids in many industries in a wide range of applications, such as mine drainage, dredging of sunken lagoons and pumping of drilling mud.

- In addition, a new level of complexity is added to an otherwise simple machine. Other parts must now be inventoried and training beyond basic spanner turning is required. When it comes to pumping rock and some of the world's most abrasive materials.

- With the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

Latest articles

-

When the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

-

Are the pump discharge components suitable for the slurry being pumped?

-

Heavy-Duty Slurry Pump

-

A clear clean fluid supplied from an external source is normally used which is delivered to the main sealing surface on the fluid side of the sealing process. By using a closed gap throat bushing, the stuffing box can be back-pressurised to a higher pressure, ensuring that the flushing fluid does not flash across the seal face.

-

Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

-

A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

Links

- Moreover, the combination of a memory foam topper and a fitted sheet offers a hygienic solution. The fitted sheet can be easily removed and washed, maintaining a clean and fresh sleeping environment. It also protects the topper from dirt and wear, prolonging its lifespan.

- The Elastic Single Bedsheet A Game-Changer in Comfort and Convenience

5. Tencel™

There are several key factors to consider when choosing the perfect duvet insert, with weight being one of the most important. The weight of a duvet insert can greatly affect its warmth and comfort, so it's important to understand the different options available. From ultralight to heavy-duty duvet inserts, each type serves a specific purpose and satisfies different preferences.

Pillowcase

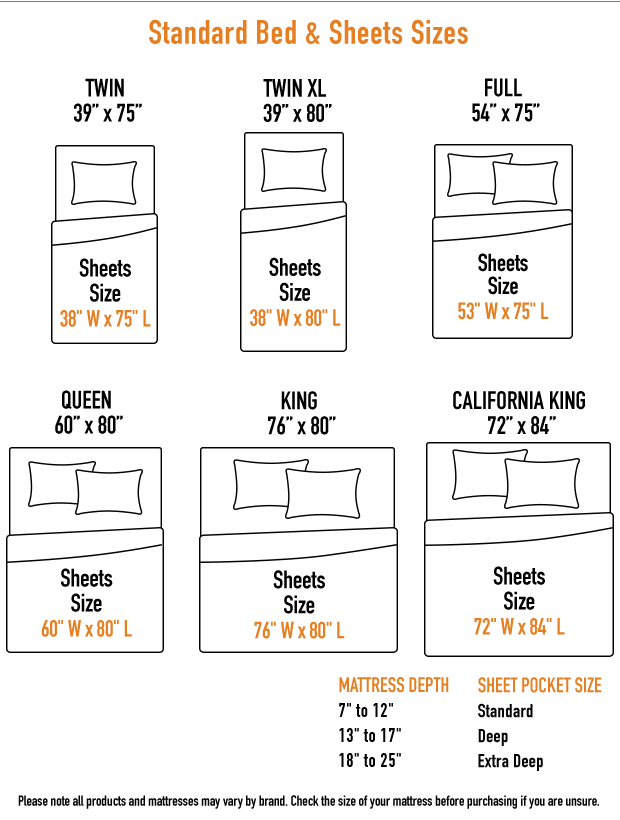

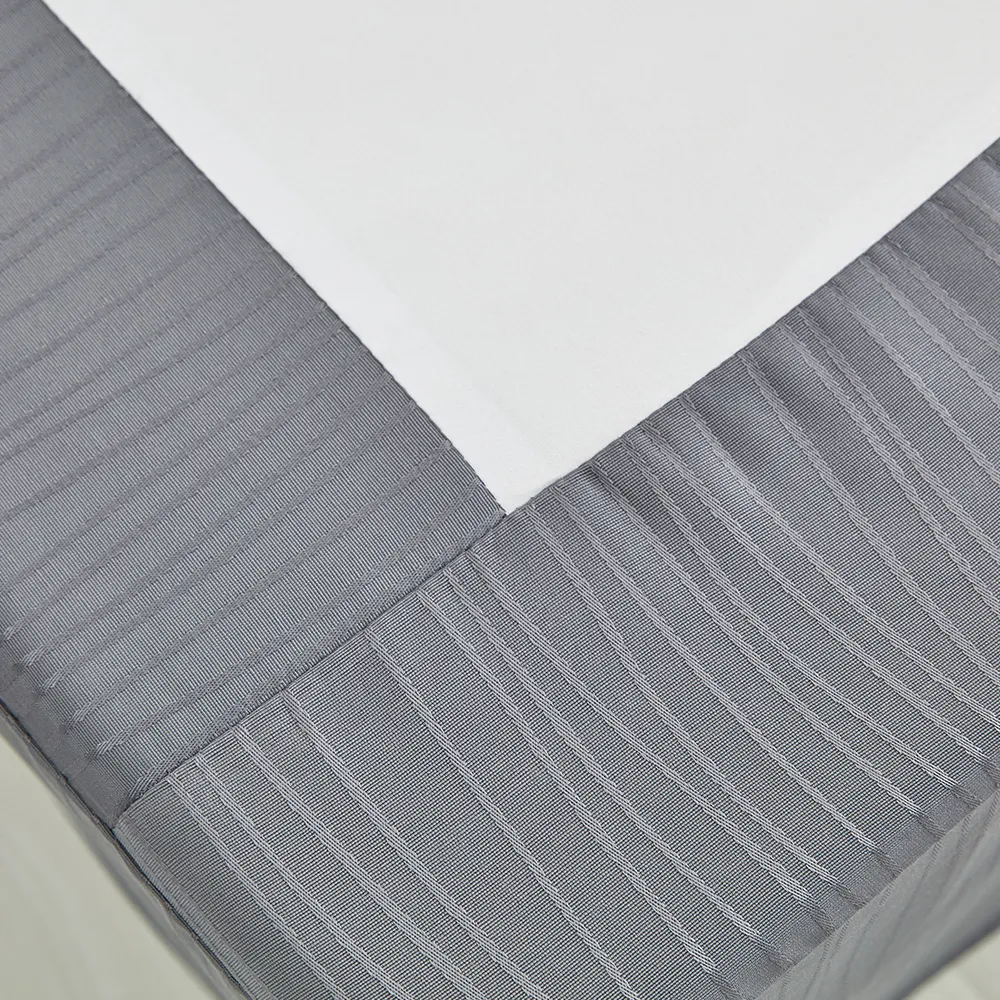

The stretchy and elastic nature of the blend also means they fit snugly on mattresses of various thicknesses, eliminating the frustration of constantly adjusting fitted sheets The stretchy and elastic nature of the blend also means they fit snugly on mattresses of various thicknesses, eliminating the frustration of constantly adjusting fitted sheets

The stretchy and elastic nature of the blend also means they fit snugly on mattresses of various thicknesses, eliminating the frustration of constantly adjusting fitted sheets The stretchy and elastic nature of the blend also means they fit snugly on mattresses of various thicknesses, eliminating the frustration of constantly adjusting fitted sheets bamboo blend sheet set.

bamboo blend sheet set.Polyester:Polyester is a fabric most people are familiar with, due to its common use in clothing. Polyester is a synthetic material and a form of plastic, making it generally inexpensive and extremely durable. It is also usually moisture-wicking, which can be a pro to hot sleepers.

Despite their delicate feel, they are surprisingly resilient, resisting wear and tear much better than many traditional sheet materials Despite their delicate feel, they are surprisingly resilient, resisting wear and tear much better than many traditional sheet materials

Despite their delicate feel, they are surprisingly resilient, resisting wear and tear much better than many traditional sheet materials Despite their delicate feel, they are surprisingly resilient, resisting wear and tear much better than many traditional sheet materials super soft bamboo sheets. They also maintain their color and sheen longer, ensuring your bedding retains its newness and elegance for extended periods.

super soft bamboo sheets. They also maintain their color and sheen longer, ensuring your bedding retains its newness and elegance for extended periods.

'Jersey feels like your favorite T-shirt and is wrinkle-resistant, but not ideal for someone who sleeps warm,' says Bed, Bath & Beyond.

Bed linen sizes

summer duvet insert. It can be used with a variety of bedding styles, including duvets, quilts, and even regular blankets. This means that you can easily adjust the level of warmth according to your personal preferences and the season. For example, you can use a lighter insert during the summer months and a heavier one during the winter.

summer duvet insert. It can be used with a variety of bedding styles, including duvets, quilts, and even regular blankets. This means that you can easily adjust the level of warmth according to your personal preferences and the season. For example, you can use a lighter insert during the summer months and a heavier one during the winter.What Sheets Are Good For Hot Weather?

Aja Tilghman says you 'can't go wrong' with linen, cotton percale, or cotton sateen, adding: 'It is a personal journey to find your favorite material. Linen offers a more textured feel and gets softer with every wash.