high quality heavy duty slurry pump factories

Latest articles

In a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

high quality heavy duty slurry pump factories...

high quality heavy duty slurry pump factories 【high quality heavy duty slurry pump factories】

Read MoreDamage to slurry pumps can range from burst seals to bearings and component housings wearing out where they join, to impellers corroding due to cavitation or severe wear and so on. However, there are solutions to these problems.

high quality heavy duty slurry pump factories...

high quality heavy duty slurry pump factories 【high quality heavy duty slurry pump factories】

Read MoreLarger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

high quality heavy duty slurry pump factories...

high quality heavy duty slurry pump factories 【high quality heavy duty slurry pump factories】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

high quality heavy duty slurry pump factories...

high quality heavy duty slurry pump factories 【high quality heavy duty slurry pump factories】

Read Moretesting station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

high quality heavy duty slurry pump factories...

high quality heavy duty slurry pump factories 【high quality heavy duty slurry pump factories】

Read MoreSettling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

high quality heavy duty slurry pump factories...

high quality heavy duty slurry pump factories 【high quality heavy duty slurry pump factories】

Read MoreSlurry pipe diameter.

high quality heavy duty slurry pump factories...

high quality heavy duty slurry pump factories 【high quality heavy duty slurry pump factories】

Read Moretesting station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

high quality heavy duty slurry pump factories...

high quality heavy duty slurry pump factories 【high quality heavy duty slurry pump factories】

Read More3. Both pumps and motors are designed separately.

high quality heavy duty slurry pump factories...

high quality heavy duty slurry pump factories 【high quality heavy duty slurry pump factories】

Read MoreHow does a dredge pump work?

high quality heavy duty slurry pump factories...

high quality heavy duty slurry pump factories 【high quality heavy duty slurry pump factories】

Read More

Popular articles

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- How Slurry Pumps Differ From Standard Pumps?

- - By increasing the size of the worm housing, the speed at which the media moves is reduced. This lower velocity translates into lower wear.

- Corrosiveness of the slurry

- Positive displacement slurry pumps with limited capacity to deliver high head are used to pump slurry through pipes with very high solids concentrations.

- Rubber Lined Slurry Pump

Latest articles

-

Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

-

One of the most frequently asked questions from our team of pump experts is: How do I pump slurry?xa0With this in mind, our team of experts have provided a useful guide to pumping slurry.

-

Desire for higher efficiency than centrifugal pumps

-

Slurry Pump

-

Using rubber as a wear lining material means

-

On the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

Links

While American bed sizes have remained fixed, there are no standard mattress depths. As a general rule, our fitted sheets have a gusset (AKA “pocket size” or “pocket depth”) that will fit mattresses up to 17” deep with enough room to tuck under the mattress. However, most of our purveyors accommodate custom orders for deeper or thinner sizes.

Role of Bed Linens: Bed linens serve multiple purposes. They protect the underlying bedding (like duvets or pillows) from wear and tear, add layers for warmth, and offer an opportunity to change the bedroom's look with different colors, patterns, and textures.

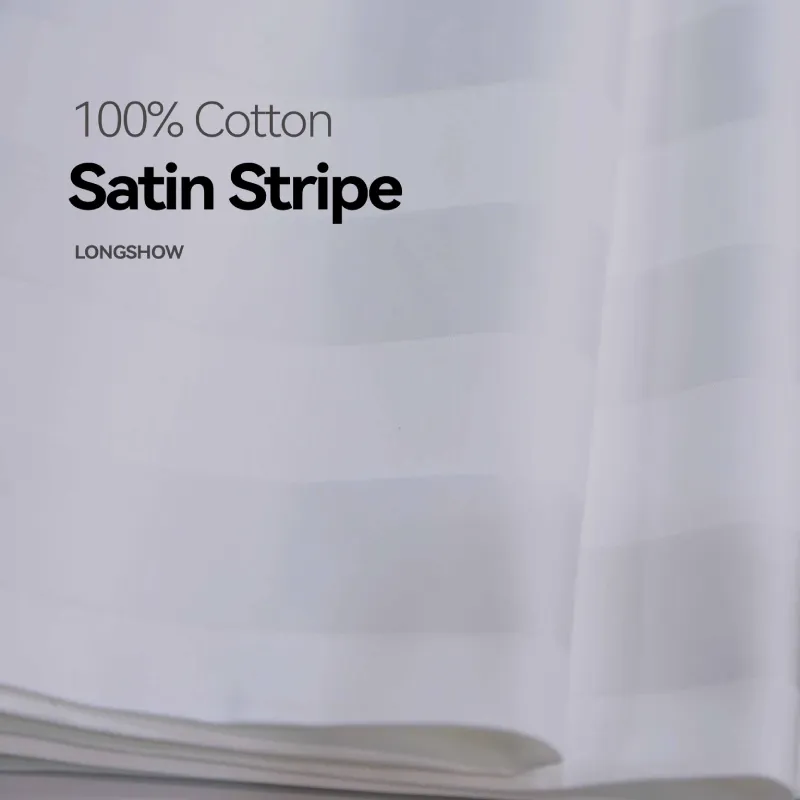

Cotton Sheets

Ply refers to the number of fibers used to create one thread. One-ply sheets have one fiber, while two-ply sheets have two fibers wrapped together to create a single thread.

polyester flat sheets. The material is designed to wick away moisture, keeping you cool in the summer and warm in the winter. This makes them an ideal choice for people with sensitive skin or those who suffer from night sweats.

polyester flat sheets. The material is designed to wick away moisture, keeping you cool in the summer and warm in the winter. This makes them an ideal choice for people with sensitive skin or those who suffer from night sweats. fluffy down alternative duvet insert. Heavier inserts are better suited for colder climates, while lighter inserts are better for warmer climates. Additionally, the weight of the insert can affect how well it insulates, so it's worth considering your personal preferences and needs.

fluffy down alternative duvet insert. Heavier inserts are better suited for colder climates, while lighter inserts are better for warmer climates. Additionally, the weight of the insert can affect how well it insulates, so it's worth considering your personal preferences and needs.Bed Valance

When choosing the perfect high quality towels, there are a few key factors to consider: absorbency, softness, and hygiene. In recent years, fiber towels, satin towels, and antibacterial towels have become popular for their unique performance and luxurious feel. Let’s delve into the world of these innovative high quality towels and discover their benefits.

The quality of your bedding plays a vital role when it comes to creating a comfortable and stylish bedroom. Finding good quality affordable bedding can sometimes be a challenge, but with the right bedding supplier and reliable bedding factory, you can easily achieve the perfect combination of comfort, style, and affordability.

This makes them an excellent choice for people with sensitive skin or respiratory issues This makes them an excellent choice for people with sensitive skin or respiratory issues

This makes them an excellent choice for people with sensitive skin or respiratory issues This makes them an excellent choice for people with sensitive skin or respiratory issues charcoal bamboo sheets.

charcoal bamboo sheets. 1800 thread count sheets. A higher thread count allows for more efficient use of available resources, while a higher sheet count enables the system to handle a greater volume of work simultaneously. Together, they form a powerful combination that can help drive peak performance in a wide range of applications.

1800 thread count sheets. A higher thread count allows for more efficient use of available resources, while a higher sheet count enables the system to handle a greater volume of work simultaneously. Together, they form a powerful combination that can help drive peak performance in a wide range of applications.Factors for Bed Sheets: Consider the material's feel and breathability, your skin's sensitivity, and the climate. Also, think about ease of care – for instance, if you dislike ironing, look for wrinkle-resistant options.

washable duvet insert. A higher fill power generally indicates better insulation and a fluffier feel. The weight of the insert is another important consideration, depending on your personal preference and climate.

washable duvet insert. A higher fill power generally indicates better insulation and a fluffier feel. The weight of the insert is another important consideration, depending on your personal preference and climate. charcoal sheet size. They can also be used for writing. The charcoal powder adheres to the paper, making it easy to write with and erase. This unique property makes charcoal sheets a popular choice for writers who want a more tactile writing experience.

charcoal sheet size. They can also be used for writing. The charcoal powder adheres to the paper, making it easy to write with and erase. This unique property makes charcoal sheets a popular choice for writers who want a more tactile writing experience.