polyurethane slurry pump

Latest articles

In a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

polyurethane slurry pump...

polyurethane slurry pump 【polyurethane slurry pump】

Read MoreSelecting And Operating A Slurry Pump

polyurethane slurry pump...

polyurethane slurry pump 【polyurethane slurry pump】

Read MoreTypically, slurries are.

polyurethane slurry pump...

polyurethane slurry pump 【polyurethane slurry pump】

Read MoreAs the slurry is collected at the bottom of the tower, more rubber lined pumps are required to transfer the slurry to storage tanks, tailings ponds, waste treatment facilities or filter presses. Depending on the type of FGD process, other pump models are available for slurry discharge, pre-scrubber recovery and catch basin applications.

polyurethane slurry pump...

polyurethane slurry pump 【polyurethane slurry pump】

Read MoreFor certain types of slurry pumping conditions, positive displacement pumps may be a more suitable option than centrifugal pumps.

polyurethane slurry pump...

polyurethane slurry pump 【polyurethane slurry pump】

Read MoreAdapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

polyurethane slurry pump...

polyurethane slurry pump 【polyurethane slurry pump】

Read MoreIf you have experience pumping slurries, you know it's not an easy task. Slurries are heavy and difficult to pump. They cause excessive wear on pumps and their components and are known to clog suction and discharge lines if not moving fast enough. Most importantly, it’s a challenge to make slurry pumps last for a reasonable amount of time. But, there are a few things you can do to extend the life of your slurry pump and make pumping slurry less of a challenge.

polyurethane slurry pump...

polyurethane slurry pump 【polyurethane slurry pump】

Read More2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

polyurethane slurry pump...

polyurethane slurry pump 【polyurethane slurry pump】

Read MoreSlurry Pump Selection

polyurethane slurry pump...

polyurethane slurry pump 【polyurethane slurry pump】

Read MoreBCT Ceramic Slurry Pumps

polyurethane slurry pump...

polyurethane slurry pump 【polyurethane slurry pump】

Read More

Popular articles

- >Dredge Pump

- Advantages of rubber

- The Difference Between Flushing And Quenching in Slurry Pump Seals

- Caution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

- Determine the nature of the material to be pumped

- Repairable - target=_blank title=Rubber Lined Slurry Pumps>Rubber lined slurry pumps can be repaired by simply replacing the bushing.

Latest articles

-

WA Heavy-duty Slurry Pump

-

Slurry Pump

-

Rubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

-

Slurry Pump

-

Settling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

-

When flushing is required, the >slurry pump supplier recommends the API Option 32 sealed pipe arrangement as it is more suitable for services containing solids or contaminants that could damage the seal faces if recirculated in the flushing medium.

Links

Hydroxypropyl Methylcellulose (HPMC) has emerged as a vital ingredient in the construction industry, particularly in the formulation of mortars. As a non-ionic, water-soluble polymer derived from cellulose, HPMC offers numerous advantages that enhance the performance of mortar, making it an essential component in modern construction practices.

The solubility of HPMC is influenced by several factors, including its molecular weight, degree of substitution, and the nature of the solvent. In general, HPMC is known to be soluble in water and various polar solvents. However, its solubility in ethanol can present unique challenges and opportunities

- Hydroxyethyl cellulose has several unique properties that make it a valuable ingredient in a wide range of products. It is highly water-soluble and can form transparent and stable gels in aqueous solutions. This makes it an excellent thickening agent for a variety of applications such as paints, adhesives, and personal care products.

3. Moisture Content HPMC is hygroscopic, meaning it can absorb moisture from the environment. This absorption can lead to variations in density, especially when HPMC is stored in humid conditions. The presence of water can cause swelling of the polymer, thus changing the volume and density.

- Purity and Quality Ensure that the product meets your requirements for purity, especially if you are using it in cosmetics or food applications.

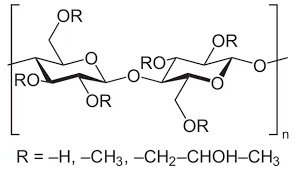

The physical and chemical properties of hydroxyalkyl cellulose can be tailored by adjusting the degree of substitution and the molecular weight during its synthesis. This adaptability allows manufacturers to customize HAC for specific applications, meeting the diverse needs of various industries. Furthermore, HAC is environmentally friendly, as it is derived from renewable biomass (cellulose) and is biodegradable, making it an attractive alternative to synthetic polymers.

Environmental Impact and Sustainability

As China continues to grow as a powerhouse in the pharmaceutical and food sectors, the importance of HPMC cannot be overstated. Its versatile applications in drug formulation and food processing highlight its significance in meeting the evolving market demands. As the industry progresses towards sustainability and innovation, HPMC will undoubtedly play a pivotal role in shaping the future of these sectors in China and beyond. The ongoing development and application of HPMC underscore a promising path forward, both economically and environmentally, making it a key player in modern industry.

The production of hydroxyethyl cellulose starts with cellulose, which is typically extracted from sources like wood pulp, cotton, or other fibrous plants. The cellulose obtained from these sources is characterized by long chains of glucose units, making it a complex carbohydrate. The natural structure of cellulose is rigid and insoluble in water, which necessitates a series of chemical modifications to enhance its solubility and functionality.

2. Online Marketplaces Platforms such as Amazon, eBay, and Alibaba can be valuable resources for purchasing HEC. Many vendors sell HEC in bulk or smaller quantities, catering to different customer needs. When purchasing from these marketplaces, it’s essential to check reviews and seller ratings to ensure the quality of the product. Additionally, be mindful of shipping times and costs, which can vary significantly.

When purchasing hydroxyethyl cellulose, consider the following factors

One of the distinguishing characteristics of MHEC is its water-solubility. When mixed with water, MHEC forms a clear, viscous solution, making it an excellent thickening agent for a variety of formulations. The degree of substitution and the viscosity grade can be adjusted during its production, allowing manufacturers to tailor MHEC for specific applications. The addition of hydroxyethyl groups not only increases its hydrophilicity but also improves its thermal stability, making MHEC suitable for high-temperature applications.

Overall, the unique properties of HPMC make it a versatile material that finds applications in various industries. From pharmaceuticals to construction, food to personal care, HPMC plays a crucial role in improving the quality and performance of products. As technology continues to advance, the demand for HPMC is expected to grow, driving further innovation and development in its uses and applications.

Investment Considerations

5. Eco-Friendliness As consumer demands shift towards more sustainable products, the use of HPMC, derived from natural sources, positions detergent manufacturers favorably. HPMC is biodegradable, which aligns with the growing trend towards environmentally-friendly cleaning solutions. This aspect is particularly appealing to eco-conscious consumers, making products with HPMC more marketable.

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether widely utilized in various industries, including pharmaceuticals, food, cosmetics, and construction. Its unique properties, such as water solubility, film-forming ability, and biodegradability, make it a valuable component in many formulations. This article will focus on the different types of HPMC, their characteristics, and their applications.

Applications of HPMC

When selecting a HPMC supplier in China, several factors should be considered to ensure a successful partnership

The food industry has also embraced HPMC due to its emulsifying, thickening, and stabilizing properties. As a food additive, it is designated as E464. HPMC is commonly used in gluten-free products, where it enhances texture and moisture retention, compensating for the lack of gluten, which provides elasticity in traditional baked goods. Its thermoreversible gel properties are beneficial in creating stable emulsions and foams, thus enhancing food texture and shelf-life.

use of hydroxypropyl methylcellulose

3. Storage and Stability HEC should be stored in a cool, dry place away from direct sunlight and incompatible materials. Proper storage ensures the stability and usability of the product over extended periods.

Hydroxypropyl methylcellulose is a valuable compound with a myriad of applications across several industries. When looking to buy HPMC, it is essential to consider factors such as grade, viscosity, supplier reputation, pricing, and regulatory compliance. By taking these considerations into account, you can ensure that you select the right product for your specific needs, ultimately enhancing the quality and effectiveness of your formulations. Whether you are in pharmaceuticals, food production, or construction, HPMC will continue to be a dependable ingredient that contributes significantly to various applications.

china mhec-methhyl hydroxyethyl cellulose supplier. Manufacturers in China adhere to strict manufacturing standards and regulations to ensure that MHEC meets the highest quality requirements. This dedication to quality has made China a trusted supplier of MHEC for many global companies.

In the construction industry, HPMC 4000 is valued for its role as an additive in cement and mortar formulations. It enhances the workability of these materials, allowing for easier application and improved adhesion. Additionally, HPMC’s water-retention properties are critical in preventing the premature drying of mortar, thereby ensuring better curing and strength of the finished product.

Environmental Considerations

Viscosity Characteristics

What is Glass Transition Temperature (Tg)?

4. Pure Acrylic Polymers

Understanding Different Grades of HPMC

3. Organic Solvents While HPMC is primarily water-soluble, the chart also provides insights into its solubility in organic solvents. Grades of HPMC may exhibit varying degrees of solubility in organic solvents like ethanol or methanol, which can aid in the formulation of certain products, especially in the cosmetic or food industries.

In the cosmetics industry, hydroxyethylcellulose is prized for its excellent film-forming properties, which help improve the adhesion of products to the skin or hair. It acts as a thickener in shampoos, conditioners, lotions, and serums, providing a luxurious feel and enhanced spreadability. The versatility of HEC allows formulators to create products that cater to various skin types and consumer preferences. Furthermore, as consumers become increasingly aware of the ingredients in their personal care products, the demand for natural and safe components like HEC has risen, making it an attractive option for manufacturers looking to meet consumer needs.

hydroxyethylcellulose for sale

HPMC is a semi-synthetic polymer derived from natural cellulose. Cellulose, commonly obtained from wood pulp or cotton, undergoes etherification to yield hydroxypropyl and methyl substitution groups. The extent of these substitutions varies, resulting in different grades of HPMC. The chemical structure of HPMC consists of a backbone of glucose units linked by β-1,4-glycosidic bonds, similar to that of cellulose.

Safety Profile

In cosmetics and personal care products, HPMC is utilized for its film-forming, emulsifying, and thickening properties. It is present in formulations ranging from shampoos and conditioners to lotions and creams, where it contributes to improved product stability and user experience.

In construction, HPMC plays a pivotal role in the formulation of mortars, adhesives, and plasters. The performance of these materials can be drastically improved by selecting the appropriate grade of HPMC. Higher viscosity grades are typically employed in tile adhesives and dry-mix mortars to enhance workability, water retention, and adhesion properties. The ability of HPMC to retain water is particularly important in construction applications, as it allows for longer working times and improved setting properties.

Construction Industry

HPMC Cellulose A Versatile Polymer in Modern Applications

what is hydroxyethyl cellulose used for. It also helps to reduce shrinkage and cracking during the curing process, resulting in a more durable and long-lasting finish.

Applications of HPMC in Construction

vae redispersible powder.