china centrifugal pump wastewater factories

Latest articles

Some quench seals are planned to replace the tight fitting outlet restriction with a secondary seal and a top outlet that can be piped to capture the used quench fluid and drain it from the rotating assembly. However the principle is the same, we try to cool the seal rather than flush it in any way.

china centrifugal pump wastewater factories...

china centrifugal pump wastewater factories 【china centrifugal pump wastewater factories】

Read MoreIf pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

china centrifugal pump wastewater factories...

china centrifugal pump wastewater factories 【china centrifugal pump wastewater factories】

Read More>Vertical Slurry Pump

china centrifugal pump wastewater factories...

china centrifugal pump wastewater factories 【china centrifugal pump wastewater factories】

Read MoreIn addition, a new level of complexity is added to an otherwise simple machine. Other parts must now be inventoried and training beyond basic spanner turning is required. When it comes to pumping rock and some of the world's most abrasive materials.

china centrifugal pump wastewater factories...

china centrifugal pump wastewater factories 【china centrifugal pump wastewater factories】

Read MoreWhat is the optimum seal arrangement for the application?

china centrifugal pump wastewater factories...

china centrifugal pump wastewater factories 【china centrifugal pump wastewater factories】

Read MoreSlurry pump vs mud pump

china centrifugal pump wastewater factories...

china centrifugal pump wastewater factories 【china centrifugal pump wastewater factories】

Read MoreStep 1

china centrifugal pump wastewater factories...

china centrifugal pump wastewater factories 【china centrifugal pump wastewater factories】

Read MoreThe terms slurry pump and dredge pump can be used interchangeably.

china centrifugal pump wastewater factories...

china centrifugal pump wastewater factories 【china centrifugal pump wastewater factories】

Read MoreHow does a dredge pump work?

china centrifugal pump wastewater factories...

china centrifugal pump wastewater factories 【china centrifugal pump wastewater factories】

Read MoreOne of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

china centrifugal pump wastewater factories...

china centrifugal pump wastewater factories 【china centrifugal pump wastewater factories】

Read More

Popular articles

- >Slurry pump impeller is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

- Determine the size of the pump

- Slurry pumps can be used for.

- Discharge ports can be placed at 45 degree intervals and oriented in up to 8 different positions depending on your needs.

- Types of slurry pumps

- Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

Latest articles

-

A dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

-

Some models can generate discharge pressures up to 260 ft. (80 m).

-

Examples of these dubious enhancements to impeller adjustment abound in the industry. One of these is the adjustable wear ring or suction liner to maintain the recommended clearance between the impeller front shroud and the throat bushing face. Almost all >slurry pumps, including AIER® slurry pumps, have features to ensure that this equipment specification can be maintained over time.

-

Consideration should be given to installing mixers on guide rods in the catch basin/tank to keep solids in suspension and avoid settling in the catch basin/tank. When investing in a slurry pump, you want to pump slurry that includes solids, not just dirty water. Therefore, it is important to make sure that the pump is doing this; by using an agitator, the pump is fed with solids and pumping the slurry.

-

Slurry Pump

-

Choosing Dry Slurry Pumps Versus Submersible Slurry Pumps

Links

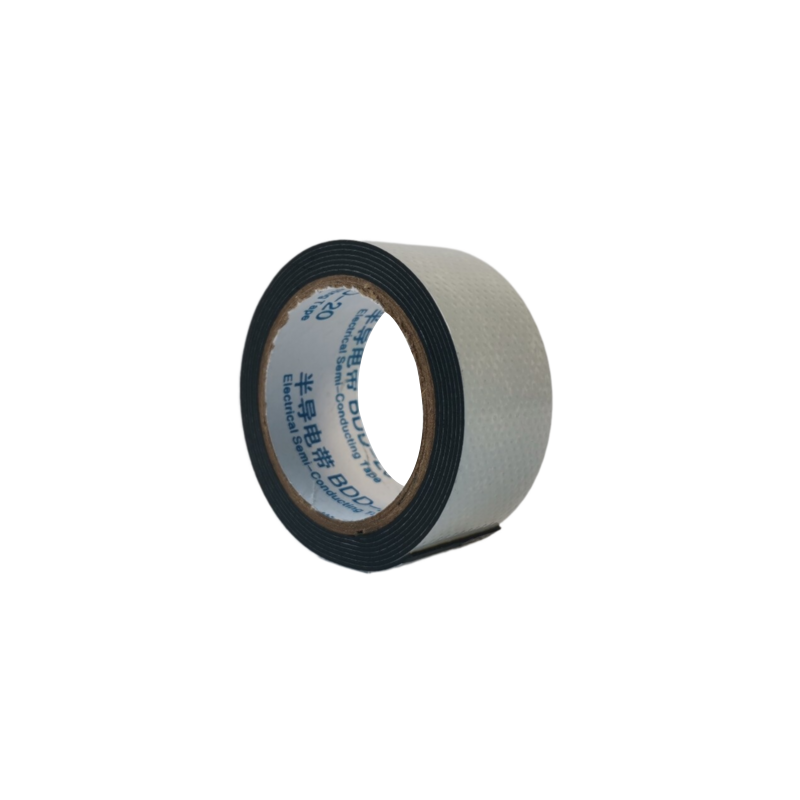

Self-fusing silicone rubber products were first created in the United States in the 1950s. The technology was originally developed by university scientists and engineers for the US military, who wanted an alternative to PVC electrical tape.

flex tape 4.

So if you need to apply electrical tape to something that may get hot, rest assured knowing that it can withstand temperatures up to 200°F. Just be sure to check the label before making your purchase, as some tapes are rated for even higher temperatures.

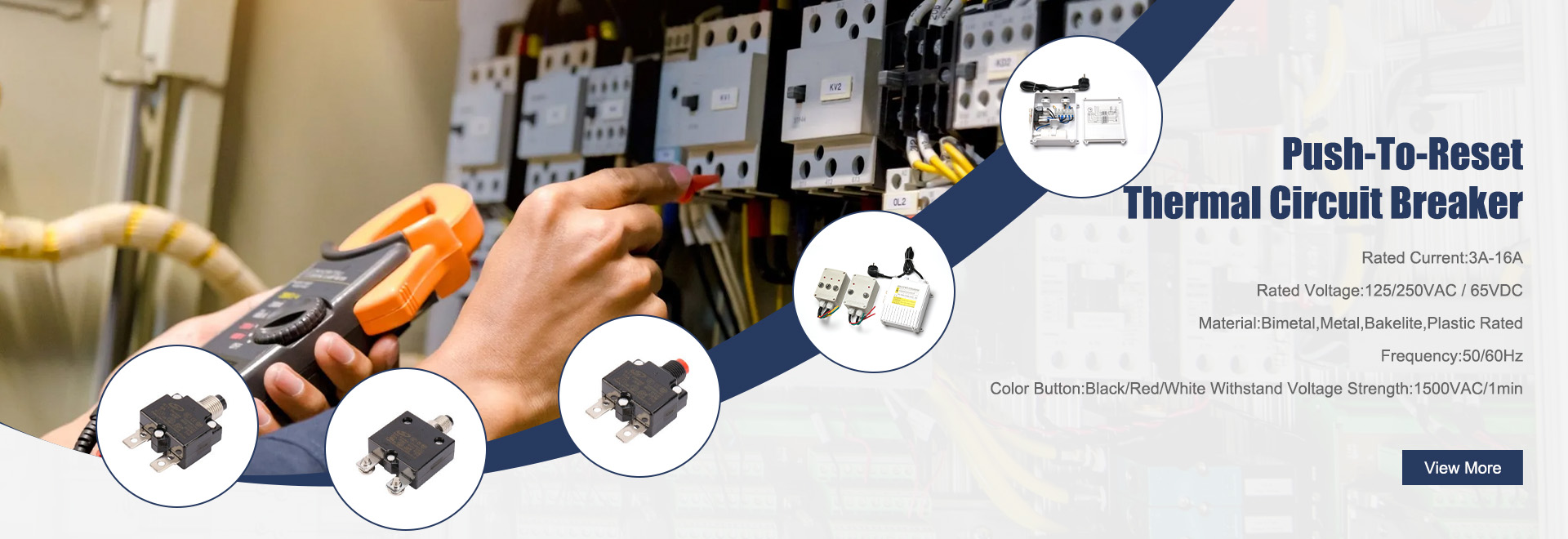

Industrial Hydraulic Electrical Control Boxes

UV, moisture and chemical resistant.

The Importance of Choosing the Right Butyl Rubber Tape Supplier

waterproof door seal strip. A tight seal around the door prevents sound from traveling through the gaps, creating a quieter and more peaceful environment. This can be particularly beneficial for homes or buildings located in noisy neighborhoods or areas with high traffic.

Self-fusing silicone electrical tape represents a significant advancement in electrical insulation technology. Its combination of high-temperature resistance, water and chemical resilience, and self-adhering properties makes it an ideal choice for a wide array of applications. Whether for professional use in industrial settings or handy DIY repairs at home, self-fusing silicone tape provides a reliable and effective solution for protecting and insulating electrical components. As awareness of its benefits grows, it is likely that this innovative product will continue to gain popularity among electricians and gardeners alike, effectively redefining the standards for electrical insulation.

2. Outdoor Furniture Maintenance Whether it's a tear in an outdoor umbrella or a broken patio chair, Flex Tape can help you salvage your outdoor investments without having to replace them entirely.

Thin (it is only 0.5mm thick)

non flammable tape.

Overall, 3mm electrical tape is a handy tool to have in any toolbox or workshop. Its small size, flexibility, and durability make it ideal for a wide range of electrical and wiring projects. Whether you are a professional electrician or a DIY enthusiast, having a roll of 3mm electrical tape on hand can save you time and effort when working on electrical repairs or installations.