high quality warman slurry pump spares manufacturer

Latest articles

Light-duty Slurry Pump

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MorePumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreWhat is the best seal arrangement for the application?

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read More2. All have vertical pumps and horizontal pumps and can convey slurry.

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreSlurry Pump

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreThere are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read More- Hydraulic efficiency is as important as the material, as efficiency is related to wear. The swept-back design of the impeller blades minimises the separation of solids from the carrying fluid, resulting in a more uniform flow. This results in a slower wear rate.

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read MoreWhy would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

high quality warman slurry pump spares manufacturer...

high quality warman slurry pump spares manufacturer 【high quality warman slurry pump spares manufacturer】

Read More

Popular articles

- Corrosiveness of the slurry

- What style of pump is suitable?

- As described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

- - Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

- What is a slurry pump?

- A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

Latest articles

-

If the exact in-pump viscosity of the product is unknown, CSI can help

-

Our firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

-

Slurry Pump Speed

-

The same point of slurry pump and mud pump

-

The Company Adopts Advanced Computer Aided Engineering Software

-

Types of damage to slurry pumps

Links

- One common application of the Fibonacci sequence is the Fibonacci loopsew, which is a loop that repeats a sequence of movements based on the Fibonacci numbers. The loopsew starts with two movements, A and B, and then repeats those movements in a sequence determined by the Fibonacci numbers. For example, if the Fibonacci sequence is 0, 1, 1, 2, 3, the loopsew would repeat movements A, B, B, A, B, A, B, B, A, B, B, A, A, B, and so on.

Presser Foot Pressure:

5. Additional Accessories Some overlock machines come bundled with accessories such as foot pedals, thread kits, and extra sewing feet. While these accessories can add to the initial cost, they can save you money in the long run by reducing the need for additional purchases.

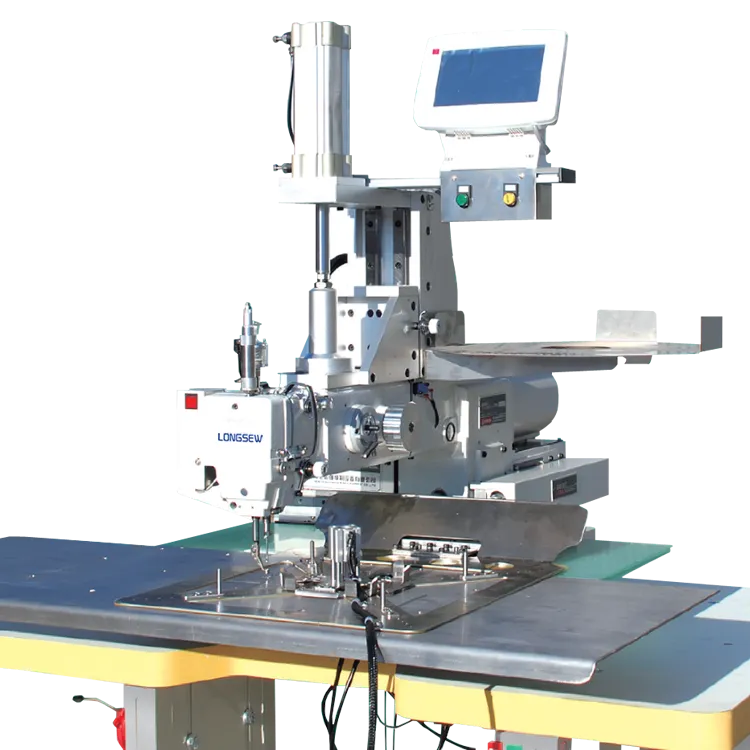

- In addition to its technical prowess, our special sewing machine is also designed with the user in mind. It features a large, easy-to-read display screen and intuitive controls that make it a breeze to navigate through settings and select the desired stitch. And with its lightweight and compact design, this machine is easy to transport and store, making it a versatile tool for seamstresses on the go.

Conclusion