froth slurry pump manufacturer

Latest articles

- Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

froth slurry pump manufacturer...

froth slurry pump manufacturer 【froth slurry pump manufacturer】

Read More>Slurry Pump

froth slurry pump manufacturer...

froth slurry pump manufacturer 【froth slurry pump manufacturer】

Read MoreA >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

froth slurry pump manufacturer...

froth slurry pump manufacturer 【froth slurry pump manufacturer】

Read MoreEspecially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

froth slurry pump manufacturer...

froth slurry pump manufacturer 【froth slurry pump manufacturer】

Read MoreAier Machinery has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

froth slurry pump manufacturer...

froth slurry pump manufacturer 【froth slurry pump manufacturer】

Read MoreTypical Applications of slurry pump

froth slurry pump manufacturer...

froth slurry pump manufacturer 【froth slurry pump manufacturer】

Read MoreWY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

froth slurry pump manufacturer...

froth slurry pump manufacturer 【froth slurry pump manufacturer】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

froth slurry pump manufacturer...

froth slurry pump manufacturer 【froth slurry pump manufacturer】

Read MoreDefinition of dredge and slurry pumps

froth slurry pump manufacturer...

froth slurry pump manufacturer 【froth slurry pump manufacturer】

Read MoreAnother important target=_blank title=Part of the Slurry Pump>part of the slurry pump is its casing, which bears all the pressure. The slurry pump casing should have a large clearance between the impeller and the diversion angle to reduce wear and prevent large solid particles from getting stuck. Due to the extra space, there is more recirculation in the slurry pump casing under various operating conditions. Again, this accelerates wear compared to typical pumps.

froth slurry pump manufacturer...

froth slurry pump manufacturer 【froth slurry pump manufacturer】

Read More

Popular articles

- Step 4

- Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

- What is a dredging pump?

- If you have experience pumping slurry, you know it is not an easy task. Slurries are heavy and difficult to pump. They can cause excessive wear on the pump and its components, and if they don't move fast enough, they can clog the suction and discharge lines. Most importantly, it can be a challenge to keep a slurry pump in use for a reasonable period of time. However, there are steps you can take to extend the life of your slurry pump and reduce the challenges of pumping slurry.

- Determine the nature of the material to be pumped

- The most important thing here is to determine the pump power required to deliver a specific fluid flow at the desired or required differential pressure. Consider the following.

Latest articles

-

The Difference Between Flushing And Quenching in Slurry Pump Seals

-

Customised pumps

-

Pumping slurry can present some challenges and problems, but with proper engineering and equipment selection, you can experience years of trouble-free operation. It's important to work with a qualified engineer when selecting a slurry pump, because slurry can wreak havoc on a pump if not selected properly.

-

With the development of the dredging market, the requirements for dredging equipment are getting higher and higher, and the suction resistance and vacuum of dredging pumps are getting higher and higher, which has a great impact on the efficiency of dredging pumps and the chance of cavitation is getting higher and higher. The number of >dredging pumps is also increasing.

-

As described below, there are several , types of pumps, that are suitable for pumping slurries. However, before considering which technology to use, we must address several key issues.

-

The Company Adopts Advanced Computer Aided Engineering Software

Links

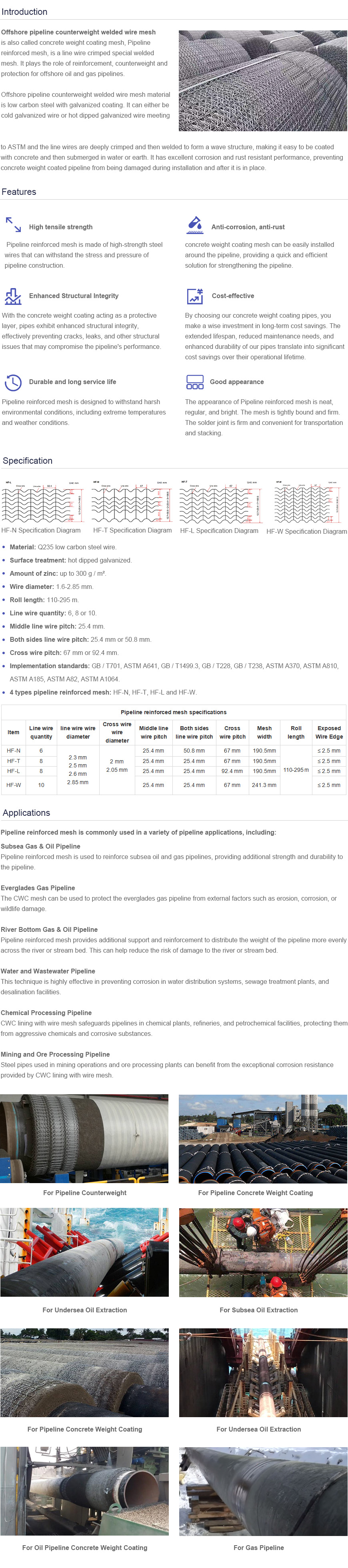

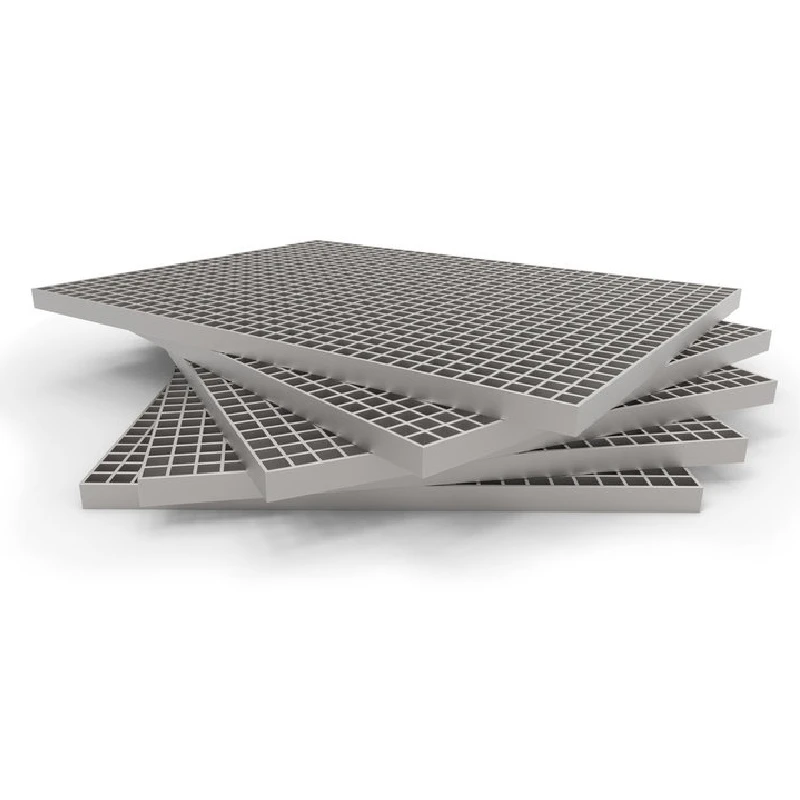

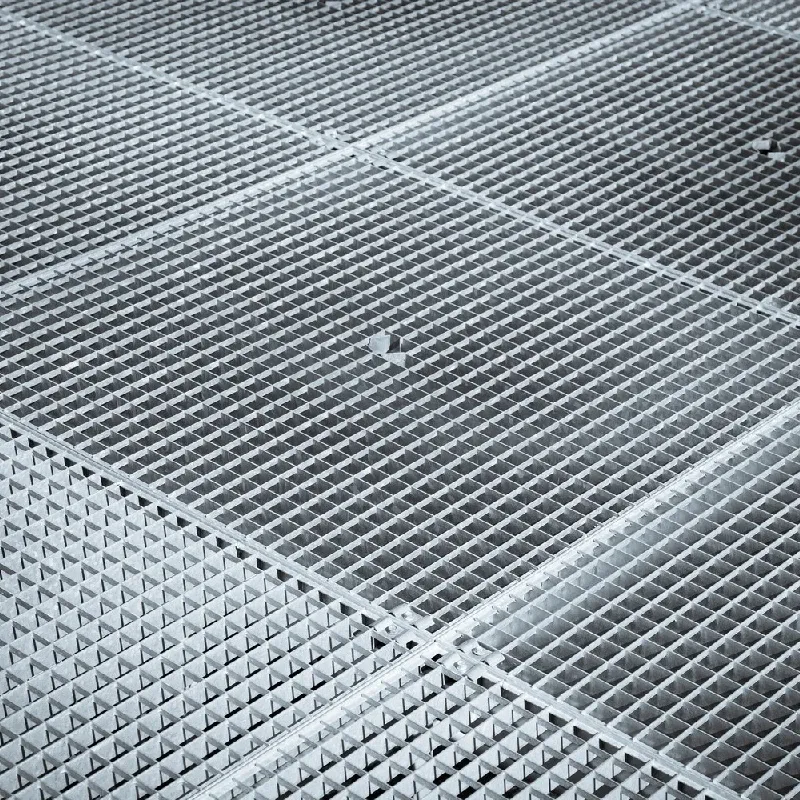

Steel grating is used to cover a portion of the structure and flooring that requires for instance light, liquid, air, heat, and sound to pass through. It is an ideal choice for projects ranging from trenches and stair treads to decking and steel flooring. Although not completely covered, steel grating is strong enough to support loads such as humans. Since the plates are positioned in a manner that can increase their strength. However, they are not suitable to resist bearing load from the structures and should not be used as a frame, beam, or column.

Além de suas propriedades físicas, os gratings de aço também contribuem para a sustentabilidade. A longo prazo, esses materiais exigem menos manutenção e substituições, resultando em uma menor formação de resíduos e consumo de recursos naturais. Além disso, o aço é um material 100% reciclável, reforçando ainda mais sua importância em práticas de construção sustentáveis.

Understanding Metal Grating Sizes A Comprehensive Overview

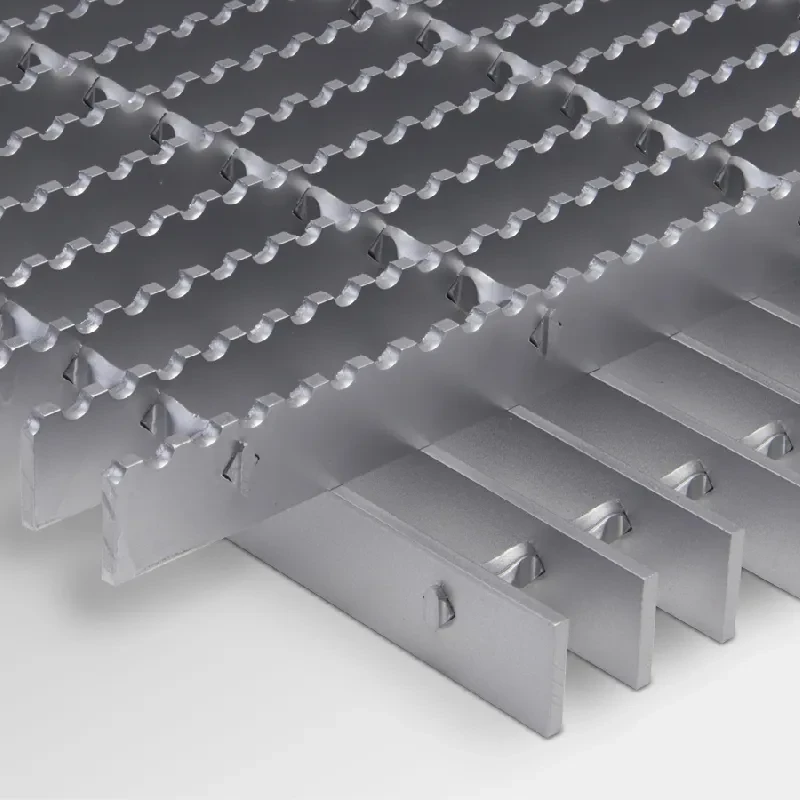

Serrated grating is an innovative optical component that has garnered attention in various fields of research and technology. At its core, serrated grating involves a periodic structure with distinct serrations or notches that alter the way light interacts with the surface. This unique configuration enables the grating to effectively manipulate light in ways that traditional smooth gratings cannot achieve, leading to a range of applications across spectroscopy, laser systems, and telecommunications.