china warman vertical sump pump factory

Latest articles

The rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

china warman vertical sump pump factory...

china warman vertical sump pump factory 【china warman vertical sump pump factory】

Read More- Lower operating costs - Typically, submersible slurry pumps require much lower operating costs than dry mounted pumps due to higher efficiency.

china warman vertical sump pump factory...

china warman vertical sump pump factory 【china warman vertical sump pump factory】

Read MoreDefinition of dredge and slurry pumps

china warman vertical sump pump factory...

china warman vertical sump pump factory 【china warman vertical sump pump factory】

Read MoreWhat is a slurry?

china warman vertical sump pump factory...

china warman vertical sump pump factory 【china warman vertical sump pump factory】

Read MoreFind a professional slurry pump supplier

china warman vertical sump pump factory...

china warman vertical sump pump factory 【china warman vertical sump pump factory】

Read MoreAll manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

china warman vertical sump pump factory...

china warman vertical sump pump factory 【china warman vertical sump pump factory】

Read MoreDredge Pump Features

china warman vertical sump pump factory...

china warman vertical sump pump factory 【china warman vertical sump pump factory】

Read MoreIf youve ever pumped a slurry, you know it can be one of the most challenging fluids to work with. It is abrasive, viscous, sometimes corrosive, and contains a lot of solids. Theres no doubt that the slurry on the pump is hard. But the more you know about whats being pumped, the better your pump selection will be, resulting in longer mean time between failures.xa0Next, the , slurry pump supplier, will share the following content with you.

china warman vertical sump pump factory...

china warman vertical sump pump factory 【china warman vertical sump pump factory】

Read MoreDesire for higher efficiency than centrifugal pumps

china warman vertical sump pump factory...

china warman vertical sump pump factory 【china warman vertical sump pump factory】

Read MoreTypes of damage to slurry pumps

china warman vertical sump pump factory...

china warman vertical sump pump factory 【china warman vertical sump pump factory】

Read More

Popular articles

- The terms 'flushing' and 'quench' often seem to be confused or misused when discussing seal support schemes for >slurry pumps. As the concepts of a mechanical seal cartridge and a filled seal cartridge are slightly different, I will discuss them separately and in turn.

- Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

- 2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

- Some quench seals are planned to replace the tight fitting outlet restriction with a secondary seal and a top outlet that can be piped to capture the used quench fluid and drain it from the rotating assembly. However the principle is the same, we try to cool the seal rather than flush it in any way.

- All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

- Expertise and experience

Latest articles

-

A variety of factors must be considered to ensure a satisfactory service. Here are tips for choosing the right , pump, .xa0, In applications ranging from processing to wastewater treatment, plants often have to handle slurries. Handling this mixture of liquids and solids can be challenging and difficult. Some of the key factors in slurry pumping are the size and nature of the solids in the liquid and the type of wear they cause. Another is the corrosiveness of the liquid or mixture.

-

Definition of dredge and slurry pumps

-

Slurry Pump

-

Dredge Pump Features

-

>Slurry Pump

-

In a subsea installation, the slurry pump runs directly in the slurry and does not require a support structure, which means it is flexible and easy to install. If possible, the catch basin should be equipped with sloping walls to allow sediment to slide down into the area directly below the pump inlet. Agitators should be used when the liquid contains large amounts of solids and has a high particle density. Freestanding or side-mounted (submersible) mixers are an excellent choice for resuspended solids, especially if the catch basin is large or does not have sloping walls.

Links

Europe

- The global demand for Lithopone B311 powder continues to grow, driven by the expansion of end-use industries, particularly construction and automotive. With the increasing focus on energy efficiency and lightweight materials, the use of Lithopone B311 powder in coatings for buildings and vehicles is expected to surge.

- In a paints factory, anatase titanium dioxide plays a crucial role in determining the quality of the final product. The pigment is added to various types of paints, including water-based paints, oil-based paints, and powder coatings, to improve their performance and appearance. Anatase titanium dioxide has the ability to reflect and scatter light, which helps in achieving a vibrant and long-lasting color finish.

60 Titanium dioxide R-5566 can be widely used in indoor and outdoor coatings, latex paints, powder coatings, inks, papermaking, rubber, plastics, masterbatches.

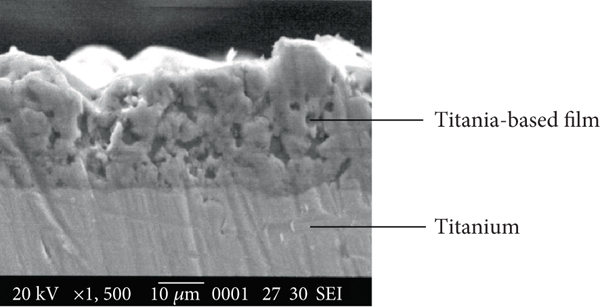

Moreover, when used as a coating on medical implants, titanium dioxide helps prevent bacterial growth and promotes osseointegration Moreover, when used as a coating on medical implants, titanium dioxide helps prevent bacterial growth and promotes osseointegration

Moreover, when used as a coating on medical implants, titanium dioxide helps prevent bacterial growth and promotes osseointegration Moreover, when used as a coating on medical implants, titanium dioxide helps prevent bacterial growth and promotes osseointegration