mining slurry pump spare parts manufacturers

Latest articles

Two types of slurry are found in these industries.

mining slurry pump spare parts manufacturers...

mining slurry pump spare parts manufacturers 【mining slurry pump spare parts manufacturers】

Read MoreHydrostatic head - i.e. the height to which the slurry must be lifted in the piping system.

mining slurry pump spare parts manufacturers...

mining slurry pump spare parts manufacturers 【mining slurry pump spare parts manufacturers】

Read Morereduce the discharge pressure of the pump to the lowest possible point, and.

mining slurry pump spare parts manufacturers...

mining slurry pump spare parts manufacturers 【mining slurry pump spare parts manufacturers】

Read MorePumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal , slurry pump, . Lets talk about how slurry pumps differ from standard pumps and how to narrow your choices.

mining slurry pump spare parts manufacturers...

mining slurry pump spare parts manufacturers 【mining slurry pump spare parts manufacturers】

Read MoreIf pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

mining slurry pump spare parts manufacturers...

mining slurry pump spare parts manufacturers 【mining slurry pump spare parts manufacturers】

Read MoreSlurry Pump

mining slurry pump spare parts manufacturers...

mining slurry pump spare parts manufacturers 【mining slurry pump spare parts manufacturers】

Read MoreCompared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

mining slurry pump spare parts manufacturers...

mining slurry pump spare parts manufacturers 【mining slurry pump spare parts manufacturers】

Read More1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

mining slurry pump spare parts manufacturers...

mining slurry pump spare parts manufacturers 【mining slurry pump spare parts manufacturers】

Read MoreSlurries are divided into two main categories: non-settling or settling. Non-settling slurries consist of very fine particles, giving the illusion of increased apparent viscosity. These slurries usually have low wear characteristics, but require very careful consideration when selecting the right pump, as they behave differently from ordinary liquids.

mining slurry pump spare parts manufacturers...

mining slurry pump spare parts manufacturers 【mining slurry pump spare parts manufacturers】

Read MoreOther manufacturers looking for differentiation, if not the end result, may choose to add a small part to their pump assembly in the description, thus allowing in-line adjustment of the wear ring in the suction side lining assembly.

mining slurry pump spare parts manufacturers...

mining slurry pump spare parts manufacturers 【mining slurry pump spare parts manufacturers】

Read More

Popular articles

- For more information about this new and improved pump, please contact us.

- What is the optimum seal arrangement for the application?

- Pumps designed to pump slurries will be heavier than pumps designed for less viscous liquids because slurries are heavy and difficult to pump.

- The frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

- The rule of thumb for setting the water pressure is the same when using the pack box, whether flushing. Mud pump shut-off pressure plus 10% or plus 20 psi, whichever is greater. However, the flow rate is set differently.

- Caution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

Latest articles

-

Depending on your own requirements, propeller seals, mechanical seals or packing seals can be used.

-

Quenching is defined as the introduction of a neutral fluid (usually water or steam) into the atmospheric side of the seal to prevent the formation of solids that may interfere with movement or be used for other purposes.

-

Why would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

-

Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel,

-

To find out more about Aier slurry Pumps, please >contact us.

-

Mixers can also help agitators when pumping very dense particles. In applications where the tank is small and/or where pumping is desired to lower the water level in the tank, a slurry pump with an internal cooling system should be considered to avoid overheating of the stator (when the water level gets low). When pumping sediment from a dam or lagoon, consider the use of a raft unit, which is a submersible device. Agitators are recommended, as well as one or more mixers that can be mounted on the raft or pump to resuspend particles for successful pumping of particles.

Links

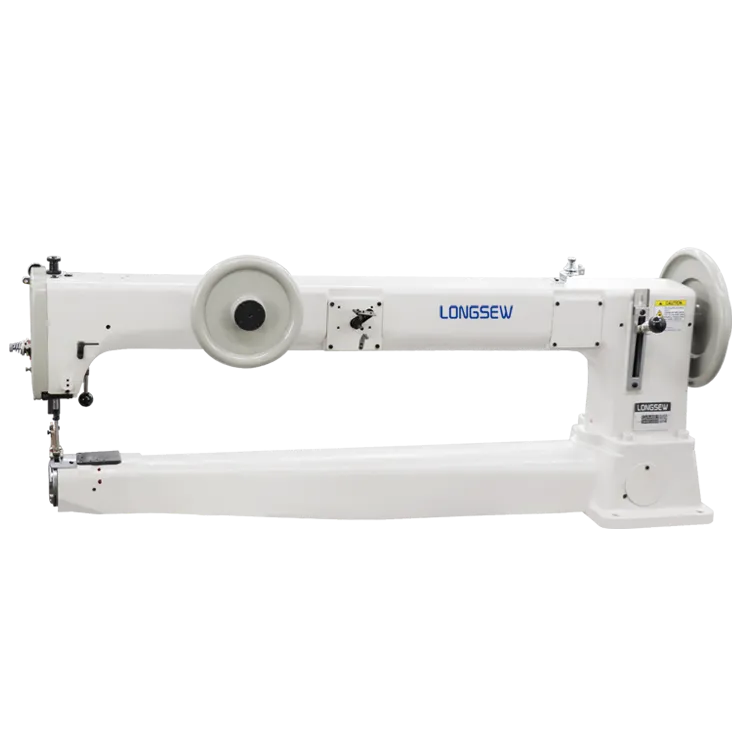

The Importance of Heavy Duty Sewing Machines in Modern Crafting

Conclusion

Conclusion

Benefits of Needle Feed Technology

needle feed sewing machine

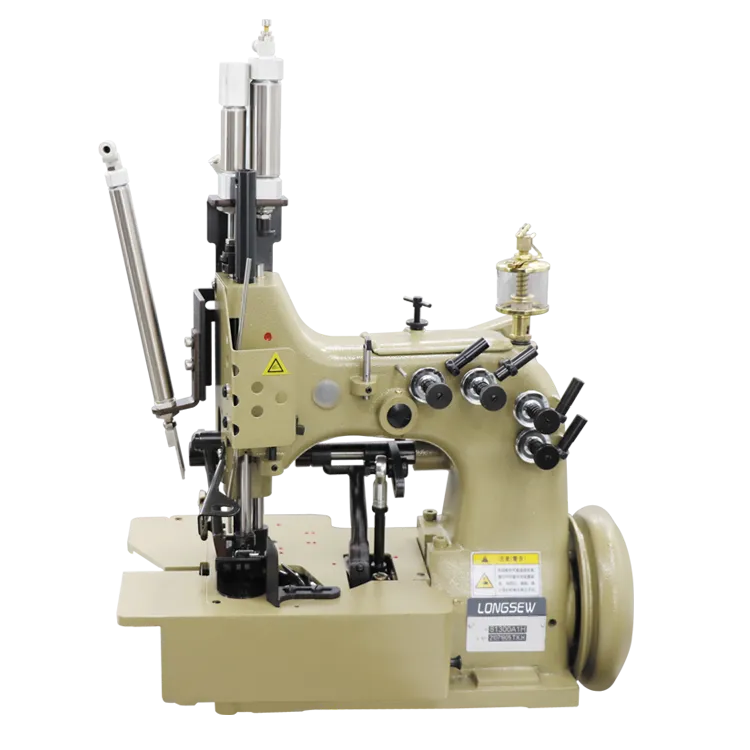

There are various types of industrial sewing machines tailored for leatherwork, including walking foot machines, post-bed machines, and cylinder-bed machines.

Heavy-duty sewing machines are specialized tools for tough jobs like leather, denim, and canvas. They are the best for strength, durability, and accuracy and are needed for making outerwear, industrial upholstery, and traditional quilting. Even though they might be more expensive to buy initially, their long-term value, as shown by user reviews and cost analysis, shows they are worth getting.

One of the major advantages of a leather manual sewing machine is its cost-effectiveness. Unlike modern electric machines, which can be expensive and maintenance-intensive, manual machines are generally more affordable and durable, often lasting for decades with proper care. The simplicity of the mechanics also means there is less that can go wrong, giving artisans confidence in their tools.

The Art of Crafting Car Mats with a Sewing Machine

When it comes to setting up a twin needle sewing machine, the process is relatively straightforward. After selecting the appropriate twin needle and thread, the sewist inserts the needle, adjusts the thread tension, and chooses a compatible stitch. Most modern sewing machines are equipped with automatic settings that make this process even easier, allowing individuals to focus more on their creativity instead of technical details.

The use of sewing machines in sofa upholstery also streamlines production processes. With the ability to work faster than traditional hand-sewing methods, these machines greatly reduce the time required to complete a project. As furniture manufacturers constantly seek ways to meet market demand efficiently, the speed and reliability of an upholstered sewing machine become invaluable. This efficiency not only benefits manufacturers but also enhances the customer experience, as consumers receive their bespoke furniture in a timely manner.

Understanding the Price of Zigzag Sewing Machines A Comprehensive Overview