wholesale rubber lined slurry pump manufacturer

Latest articles

Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High

wholesale rubber lined slurry pump manufacturer...

wholesale rubber lined slurry pump manufacturer 【wholesale rubber lined slurry pump manufacturer】

Read MoreAier is pumping experts and offer some useful tips to maintain your >slurry pump.

wholesale rubber lined slurry pump manufacturer...

wholesale rubber lined slurry pump manufacturer 【wholesale rubber lined slurry pump manufacturer】

Read MoreSlurry pump vs mud pump

wholesale rubber lined slurry pump manufacturer...

wholesale rubber lined slurry pump manufacturer 【wholesale rubber lined slurry pump manufacturer】

Read MoreSlurry Pump Speed

wholesale rubber lined slurry pump manufacturer...

wholesale rubber lined slurry pump manufacturer 【wholesale rubber lined slurry pump manufacturer】

Read MoreSlurry pump seals

wholesale rubber lined slurry pump manufacturer...

wholesale rubber lined slurry pump manufacturer 【wholesale rubber lined slurry pump manufacturer】

Read More>Slurry Pump

wholesale rubber lined slurry pump manufacturer...

wholesale rubber lined slurry pump manufacturer 【wholesale rubber lined slurry pump manufacturer】

Read MoreTwo types of slurry are found in these industries.

wholesale rubber lined slurry pump manufacturer...

wholesale rubber lined slurry pump manufacturer 【wholesale rubber lined slurry pump manufacturer】

Read Moretesting station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

wholesale rubber lined slurry pump manufacturer...

wholesale rubber lined slurry pump manufacturer 【wholesale rubber lined slurry pump manufacturer】

Read MoreWhy would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

wholesale rubber lined slurry pump manufacturer...

wholesale rubber lined slurry pump manufacturer 【wholesale rubber lined slurry pump manufacturer】

Read MoreThe mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete.

wholesale rubber lined slurry pump manufacturer...

wholesale rubber lined slurry pump manufacturer 【wholesale rubber lined slurry pump manufacturer】

Read More

Popular articles

- TL FGD Pump

- Make sure you follow the basic rules of pump piping.

- Slurry Pump VS Mud Pump

- First, what is a slurry? A slurry is a semi-liquid mixture, usually consisting of fine particles. Examples of slurries can include manure, cement, starch, or coal suspended in water. There are countless other combinations that can be considered slurries. Because of the added particles and thicker consistency, special pump requirements should be considered. A standard pump may be able to handle the fluid, but not as effectively as a properly sized slurry pump.

- What is a dredging pump?

- - Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

Latest articles

-

Slurry pumps can also simply axially adjust the clearance between the impeller and the adjacent throat casing sealing surface. This helps to maintain pump performance when internal components begin to wear.

-

Slurry pumps can be used for.

-

It is critical to determine the right slurry pump size and power requirements for your application. Depending on the abrasive nature of the slurry, it is important to select a pump size that will allow it to run at a slow enough speed to extend the life of the slurry pump. The ideal RPM to run a slurry pump is between 900 and 1200 RPM. Once that speed is started to be exceeded, the life of the pump is greatly reduced because the wear points of the slurry pump are actually sandblasted.

-

Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

-

In a subsea installation, the slurry pump runs directly in the slurry and does not require a support structure, which means it is flexible and easy to install. If possible, the catch basin should be equipped with sloping walls to allow sediment to slide down into the area directly below the pump inlet. Agitators should be used when the liquid contains large amounts of solids and has a high particle density. Freestanding or side-mounted (submersible) mixers are an excellent choice for resuspended solids, especially if the catch basin is large or does not have sloping walls.

-

Mud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

Links

- One of the key advantages of the handheld jackhammer is its portability. Weighing only a few kilograms, this tool can be easily carried by hand, allowing workers to move around the worksite with ease. This mobility is particularly useful in tight spaces where larger machinery cannot access.

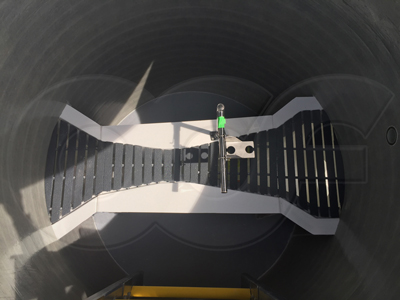

Heavy Duty Grating is used to covers areas with heavy traffic. We offer both Pultruded Heavy Duty (HD) Grating and High Load Capacity (HLC) Molded Grating.

- FRP pipe, also known as glass fiber reinforced plastic pipe, is made by embedding glass fibers into a polymer matrix. This unique composition provides the pipe with exceptional strength, flexibility, and corrosion resistance, making it an ideal choice for a wide range of applications.

- In conclusion, the button bit, though small in size, has had a monumental impact on the way we interact with technology. Its journey from being a mere concept to a fundamental component of modern devices is a testament to human ingenuity and the ceaseless pursuit of innovation. As we move towards an increasingly digital future, the button bit will undoubtedly continue to shape the landscape of human-machine interaction, making our lives more connected, convenient, and efficient.

- Powered by either air, electricity, or hydraulics, portable rock drills pack a formidable punch. Their high torque and rotational speed enable them to penetrate rocks with astonishing efficiency, making short work of even the hardest stone. Whether it's for creating blast holes, installing anchors, or conducting geotechnical investigations, these drills offer a versatile solution that adapts to diverse project requirements.

- Understanding CNAP 711 is essential for network administrators, telecommunications engineers, and developers working on applications that interact with mobile networks

- Furthermore, FRP piping systems can be custom-designed to meet specific project requirements

- One of the key advantages of fiberglass tanks is their resistance to corrosion. Unlike metal tanks, which can corrode over time when exposed to certain chemicals or saltwater, fiberglass tanks maintain their integrity even in the most challenging environments. This makes them particularly useful in wastewater treatment, where acids and alkalis are common, and in marine applications where saltwater corrosion is a constant concern.

- The term Grp Vessel might at first glance seem like a typographical error or a random set of letters and numbers, but it actually serves as an intriguing metaphor for exploration and discovery. In this context, let's consider the Grp Vessel as a symbolic vessel of exploration, akin to a ship or spacecraft, designed to navigate through uncharted waters or the vastness of space. This imaginative journey will take us on a quest for knowledge and understanding, where each percentage sign (%) represents a milestone in our pursuit of wisdom.

- Fiberglass, or glass-reinforced plastic, is a composite material made by combining fine glass fibers with a polymer matrix. This combination results in a material that possesses exceptional strength, heat resistance, and chemical stability, making it perfectly suited for the rigorous conditions prevalent in steel smelting plants.

Hengshui Jrain’s FRP products can be widely used on field of water treatment, wastewater treatment, odor control, etc.

The drilling machine allows for precise control of the drilling process, ensuring accuracy and efficiency in tunnel excavation The drilling machine allows for precise control of the drilling process, ensuring accuracy and efficiency in tunnel excavation

The drilling machine allows for precise control of the drilling process, ensuring accuracy and efficiency in tunnel excavation The drilling machine allows for precise control of the drilling process, ensuring accuracy and efficiency in tunnel excavation tunnel drilling rock drill tools. In addition to the drilling machine, rock drill tools also include support equipment such as drilling rods, drilling fluids, and safety gear to protect workers during the drilling operation.

tunnel drilling rock drill tools. In addition to the drilling machine, rock drill tools also include support equipment such as drilling rods, drilling fluids, and safety gear to protect workers during the drilling operation. Although less efficient than wet FGD, it is more suitable for smaller installations due to its lower capital cost Although less efficient than wet FGD, it is more suitable for smaller installations due to its lower capital cost

Although less efficient than wet FGD, it is more suitable for smaller installations due to its lower capital cost Although less efficient than wet FGD, it is more suitable for smaller installations due to its lower capital cost flue gas desulfurization.

flue gas desulfurization. By improving efficiency, companies can reduce operating costs, increase profitability, and enhance their competitive position in the market By improving efficiency, companies can reduce operating costs, increase profitability, and enhance their competitive position in the market

By improving efficiency, companies can reduce operating costs, increase profitability, and enhance their competitive position in the market By improving efficiency, companies can reduce operating costs, increase profitability, and enhance their competitive position in the market speed drill rod.

speed drill rod.

fiberglass stack liner. They help maintain the internal temperature of the system, reducing heat loss and improving energy efficiency. Furthermore, their non-conductive nature makes them safe to handle and reduces the risk of electrical hazards.

fiberglass stack liner. They help maintain the internal temperature of the system, reducing heat loss and improving energy efficiency. Furthermore, their non-conductive nature makes them safe to handle and reduces the risk of electrical hazards.