china abrasive slurry pump manufacturer

Latest articles

reduce the discharge pressure of the pump to the lowest possible point, and.

china abrasive slurry pump manufacturer...

china abrasive slurry pump manufacturer 【china abrasive slurry pump manufacturer】

Read MoreI hope this short blog has helped to clear up some of the confusion about the seal flush programme. Please always refer to the pump manual for specific details. If there are still questions, welcome to >contact us today.

china abrasive slurry pump manufacturer...

china abrasive slurry pump manufacturer 【china abrasive slurry pump manufacturer】

Read MoreLarger impellers made of more material. This is to compensate for the wear and tear caused by abrasive slurries.

china abrasive slurry pump manufacturer...

china abrasive slurry pump manufacturer 【china abrasive slurry pump manufacturer】

Read More- Pumping the final product in a process

china abrasive slurry pump manufacturer...

china abrasive slurry pump manufacturer 【china abrasive slurry pump manufacturer】

Read Moretesting station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

china abrasive slurry pump manufacturer...

china abrasive slurry pump manufacturer 【china abrasive slurry pump manufacturer】

Read MoreSlurry Pump

china abrasive slurry pump manufacturer...

china abrasive slurry pump manufacturer 【china abrasive slurry pump manufacturer】

Read More- Smaller, more efficient tank - Because the motor is cooled by the surrounding liquid, the submersible slurry pump can be started up to 30 times per hour, resulting in a smaller, more efficient tank.

china abrasive slurry pump manufacturer...

china abrasive slurry pump manufacturer 【china abrasive slurry pump manufacturer】

Read More>Slurry Pump

china abrasive slurry pump manufacturer...

china abrasive slurry pump manufacturer 【china abrasive slurry pump manufacturer】

Read MoreA clear clean fluid supplied from an external source is normally used which is delivered to the main sealing surface on the fluid side of the sealing process. By using a closed gap throat bushing, the stuffing box can be back-pressurised to a higher pressure, ensuring that the flushing fluid does not flash across the seal face.

china abrasive slurry pump manufacturer...

china abrasive slurry pump manufacturer 【china abrasive slurry pump manufacturer】

Read MoreSlurry Pump selection

china abrasive slurry pump manufacturer...

china abrasive slurry pump manufacturer 【china abrasive slurry pump manufacturer】

Read More

Popular articles

- Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

- Slurry pumps can be used for.

- Longer maintenance intervals

- If you want to get more information about the slurry pumps for sale, welcome to target=_blank title=Contact Us>contact us.

- A >dredge pump is a horizontal centrifugal pump that is the heart of a dredger. It is designed to handle suspended abrasive granular materials and solids of limited size. Without a dredge pump, a stranded dredger would not be able to deliver mud.

- If pump size and type are not defined, it is worth considering the following factors when selecting a dredge pump and dredge pump: type and thickness of material to be pumped, whether diesel or electric power is required, HP (kw) of engine required, pump performance data, durability, ease of maintenance and average life expectancy under normal operating conditions. life, all important attributes in the selection process. Equally important is matching the proper pipe size and composition to maintain proper material flow without clogging the pipe and to maintain the pumping output needed to get the job done.

Latest articles

-

A slurry pump is a mechanical device used for the pressure-driven transfer of a fluid mixture (aka slurry). The fluid mixture consists largely of water as a liquid and solids as minerals, sand, gravel, human excrement, drilling mud or mostly crushed material.

-

WA series target=_blank title=Heavy-Duty Slurry Pump>heavy-duty slurry pump is cantilevered, horizontal, natural rubber or hard metal lined centrifugal slurry pumps. They are designed for handling abrasive, high density slurries in the metallurgical, mining, coal, power, building material and other industry department.

-

Damage to slurry pumps can range from burst seals to bearings and component housings wearing out where they join, to impellers corroding due to cavitation or severe wear and so on. However, there are solutions to these problems.

-

The construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

-

Capacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High

-

Damage to slurry pumps can range from burst seals to bearings and component housings wearing out where they join, to impellers corroding due to cavitation or severe wear and so on. However, there are solutions to these problems.

Links

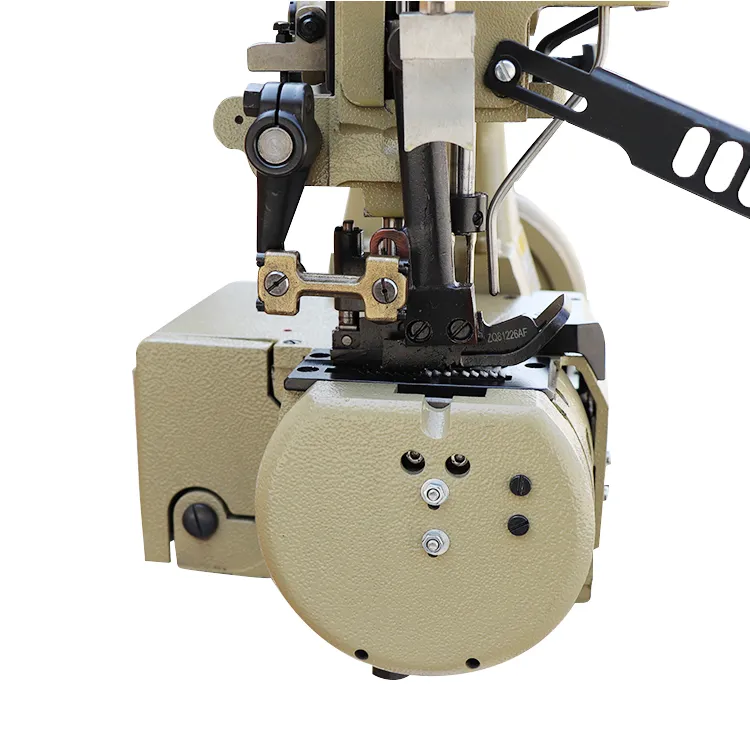

3. Versatility Many industrial sewing machines come equipped with various attachments and features that allow for a wide range of sewing techniques. From straight stitching to zig-zag and overlock stitching, these machines can handle diverse sewing projects, making them ideal for quilters, garment makers, and craft enthusiasts.

In a world where sewing has become more than just a necessity, the zigzag sewing machine stands out as a remarkable tool for creativity and efficiency. Its diverse features and wide-ranging applications make it a staple in sewing rooms around the globe. Whether you are a novice exploring the world of sewing or an experienced artisan pushing the boundaries of your craft, a zigzag sewing machine is an essential ally in bringing your visions to life. With this machine, the possibilities are truly endless, making sewing a fulfilling and enjoyable endeavor.

Another important consideration is the machine's construction quality and material durability. Industrial sewing machines designed for heavy-duty use are generally more expensive due to the quality of materials and engineering involved in their production. Investing in a robust machine can lead to long-term savings, as it may reduce maintenance costs and increase production efficiency.

Heavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

The Versatile Zigzag Foot Sewing Machine A Seamstress's Best Friend

2. Cost-Effectiveness By utilizing high-quality stitching machines, manufacturers can achieve a higher production volume at lower operational costs. This translates to increased profitability and competitiveness in the market.

Custom Accessories: Custom accessories refer to purses, belts, hats, and specialty pouches that are uniquely tailored or designed.

In the realm of textile and garment manufacturing, the significance of efficient sewing machines cannot be overstated. Among the various types available, the hi-speed lockstitch sewing machine stands out as a pivotal tool. This article delves into the meaning, functionality, and applications of hi-speed lockstitch sewing machines, illuminating their importance in the sewing industry.

One of the most popular choices among sewists is the Singer 4423. Boasting a robust motor, this machine can handle thick layers of fabric with ease, making it ideal for quilting, upholstery, and garment construction. Equipped with 23 built-in stitches, including utility, decorative, and a one-step buttonhole, it provides versatility for various sewing tasks. Users appreciate its high stitching speed of up to 1,100 stitches per minute, allowing for quicker project completion without compromising on quality.

One of the most significant advantages of automatic machine sewing is its ability to boost production speed. Traditional sewing methods often require skilled laborers to complete each step of the sewing process, which can be time-consuming and labor-intensive. In contrast, automatic sewing machines can perform numerous tasks in a fraction of the time. For example, automated machines can sew hems, attach buttons, and finish seams all in one pass, drastically reducing the time required to produce garments. This efficiency not only meets the increasing demand for faster turnaround times in the fashion industry but also contributes to cost savings.

4. Reviews and Recommendations Check user reviews and seek recommendations from other professionals in the industry to ensure you are making an informed decision.

In the world of garment manufacturing and textile arts, the right tools can significantly enhance the quality and efficiency of production. One such indispensable tool is the chain stitch sewing machine. With its unique stitching mechanism, the chain stitch machine has gained popularity among both professionals and amateur sewists alike due to its versatility and durability. If you’re considering purchasing a chain stitch sewing machine, this article will serve as a guide to understanding its features and benefits.

In summary, the precision zigzag sewing machine stands as an essential tool in the toolkit of every sewing enthusiast. Its ability to provide precision, versatility, and creativity fosters an environment where both budding creators and seasoned professionals can thrive. As sewing continues to evolve, this machine remains a steadfast ally, empowering users to bring their artistic visions to life—one stitch at a time. Whether you are mending a favorite piece of clothing, crafting a quilt, or embarking on a new sewing adventure, the precision zigzag sewing machine is indeed the perfect companion for all your sewing needs.

Advantages of Using a Double Needle Sewing Machine

The Ultimate Guide to Heavy-Duty Sewing Machines for Thick Leather

2. Robust Build Constructed with a sturdy frame, these machines are designed to withstand the rigors of frequent use. The solid construction reduces vibrations when sewing, resulting in smoother operation and increased precision.