sand dredge pump factories

Latest articles

With the standard flush schedule, the flow is usually adjusted by compressing the packings until a few drops of water are observed leaking from the seals on the drive side. In a quench schedule the flow rate is set by adjusting the inlet valve, while a valve is used on the exhaust side to maintain the correct seal tank pressure. If the outlet water from the seal box is too hot, the flow rate is increased until the outlet water cools, while still maintaining the correct seal box pressure.

sand dredge pump factories...

sand dredge pump factories 【sand dredge pump factories】

Read MoreParticle size, shape and hardness (impact on wear and corrosion potential of pump components)

sand dredge pump factories...

sand dredge pump factories 【sand dredge pump factories】

Read MoreDespite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

sand dredge pump factories...

sand dredge pump factories 【sand dredge pump factories】

Read MoreChoosing the right , slurry pump, for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the , slurry pump supplier, will share them with you.+

sand dredge pump factories...

sand dredge pump factories 【sand dredge pump factories】

Read More2.Pumping slurries poses several challenges and problems, but with proper engineering and equipment selection you can experience many years of worry-free operation. It's important to work with a qualified engineer when selecting a slurry pump because slurries can wreak havoc on a pump if not properly selected.

sand dredge pump factories...

sand dredge pump factories 【sand dredge pump factories】

Read MoreThe selection of a dredge or >slurry pump can be a challenging process that can be simplified by understanding the main factors behind the smooth operation of a pump. In addition to providing more efficient performance, the right dredge pump requires less maintenance, lower power and a relatively longer life.

sand dredge pump factories...

sand dredge pump factories 【sand dredge pump factories】

Read MoreWZ series slurry pumps are new type wear resistant & corrosion resistant slurry pump for the complexity and specificity of coal, power plant, metallurgy, chemical, building materials and other industries.

sand dredge pump factories...

sand dredge pump factories 【sand dredge pump factories】

Read MoreSlurry Pump

sand dredge pump factories...

sand dredge pump factories 【sand dredge pump factories】

Read MoreAll products are mainly supplied to environmental protection, wastewater treatment, urban water supply and drainage, mine, metallurgy, coal, petrochemical, building material, thermal power FGD, river dredging, tailing disposal and other fields.

sand dredge pump factories...

sand dredge pump factories 【sand dredge pump factories】

Read MoreStep 2

sand dredge pump factories...

sand dredge pump factories 【sand dredge pump factories】

Read More

Popular articles

- Slurry Pump Considerations

- Rubber is lighter and softer than other wear lining materials. This aids installation because it is easier to lift and install quickly and efficiently. Positive results for the health and safety of workers in the field.

- Step 3

- The basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

- Pumps with replaceable parts and components can have an unlimited service life. A high quality customised slurry pump with replaceable parts can last you a lifetime and should therefore be considered as a very reliable long-term investment.

- The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of target=_blank title=Submersible Slurry Pump>submersible slurry pump versus dry mount pumping and shares some general rules that apply to both applications. Next, the target=_blank title=Slurry Pump Manufacturer>slurry pump manufacturer will share the following content with you.

Latest articles

-

Determine the size of the pump

-

The construction aggregate industry conveys all forms of slurry, from fine sand to coarse aggregates.

-

Series of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

-

Slurry Pump

-

1.Find the spot that allows the pump to run as slow as possible (to reduce wear), but fast enough to keep solids from settling and clogging the lines.To reduce wear, lower the pump’s discharge pressure to the lowest point possible. Follow proper piping principles to ensure a constant and uniform delivery of the slurry to the pump.

-

Sump drainage or washdown

Links

Tykkfarget sveiset stangrist En løsning for holdbarhet og funksjonalitet

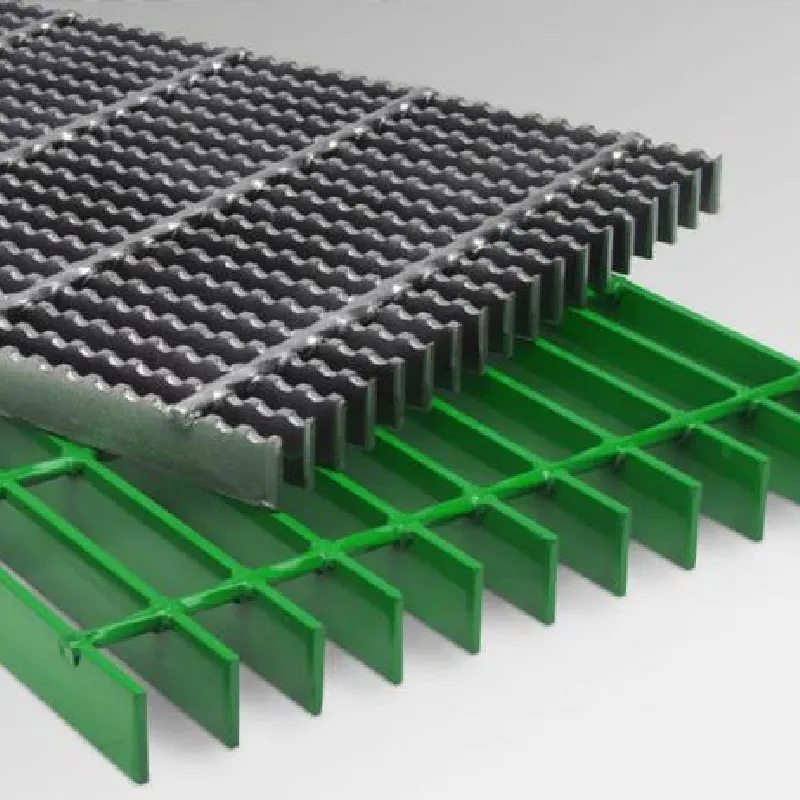

1. Mining and Mineral Processing Screens help separate ores from waste rock, increase recovery rates, and improve product purity.

اس کی تنصیب کا عمل بھی عام طور پر آسان ہوتا ہے، جیسے کہ اسے بیس اور سٹرکچر پر بچھایا جا سکتا ہے۔ اس کی مدد سے قیمتی وقت کی بچت ہوتی ہے اور کام کی تیاری کے لیے کم محنت درکار ہوتی ہے۔ اس کے فوائد میں ایک اور اہم نقطہ اس کی زندگی ہے؛ اگر درست طریقے سے دیکھ بھال کی جائے تو یہ کئی سالوں تک جاری رہتا ہے۔

Moreover, standard steel grating plays a crucial role in the oil and gas industry, where it is used in refineries and offshore platforms due to its ability to withstand harsh environmental conditions.

Um exemplo notável é o uso de gretas de rivetado em projetos de revitalização urbana, onde o objetivo é respeitar a história e a identidade de um lugar, enquanto se introduzem elementos modernos. Esses componentes podem ser integrados em espaços públicos, praças e parques, oferecendo tanto funcionalidade quanto apelo estético.

Advantages of Steel Grating

Quality Assurance

Современные города сталкиваются с множеством проблем, связанных с управлением дождевыми водами. Для решения этой проблемы активно используются лотковые дренажные системы, которые помогают отводить избыточную воду и предотвращают затопления. Одним из ключевых компонентов этих систем являются пластиковые лотковые крышки.

Applications of 19% 204% Bar Grating

19 4 bar grating

Shaker screens are available in various types, each designed to meet specific operational requirements and address different challenges encountered during drilling operations. The most common types of shaker screens include:

Galvanized Steel Grating

결론적으로, 6% 트렌치 드레인 그레이트는 현대의 다양한 환경에서 효과적인 배수 솔루션을 제공합니다. 올바른 설치와 유지보수를 통해 우리는 효율적이고 지속 가능한 배수 시스템을 구현할 수 있습니다. 따라서 모든 건축 프로젝트에서 이런 배수 시스템의 중요성을 인식하고 적절한 시스템을 선택하는 것이 필요합니다.

Benefits of Metal Mesh Gratings

metal mesh grating

Metallrippen für Treppenstufen sind in der modernen Architektur und im Bauwesen unverzichtbar geworden. Sie bieten nicht nur Sicherheit, sondern auch eine Vielzahl von funktionalen und ästhetischen Vorteilen. Diese speziellen Profile aus Metall werden häufig in öffentlichen Gebäuden, industriellen Bereichen und sogar in privaten Wohnhäusern eingesetzt. In diesem Artikel werden wir die Vorzüge und Einsatzmöglichkeiten von Metallrippen für Treppenstufen untersuchen.

ស៊ុមដែកស្រទាប់ដែលមានរាងប្លែក ស៊ុមដែកស្រទាប់ដែលមានរាងប្លែក គឺជាធាតុសំខាន់មួយក្នុងការប្រើប្រាស់ក្នុងវិស័យសំណង់ និងឧស្សាហកម្ម។ វាត្រូវបានប្រើប្រាស់យូរមកហើយក្នុងការលាយសម្រួលធ្វើសំណង់ និងការកសាងសកម្មភាពដូចជា ហាងឯកសារ ឬបុរីផ្សេងៗ ដែលត្រូវការផ្នែកកាត់ដែកដែលមានភាពកម្រ និងមានកម្រិតសុវត្ថិភាពខ្ពស់។ឈុតឈរនៃស៊ុមដែកស្រទាប់មានរាងប្លែក គឺអាចជួយបង្កើនសុវត្ថិភាពក្នុងការប្រើប្រាស់ព្រោះវាធ្វើអោយមានដំណើរការល្អពេលមានទិសដៅ និងអាចធានាថានីតិកម្មបានប្រើប្រាស់ដោយមិនបង្ហាញពីការខូចខាត។ ពីព្រោះវាគួរការពារ ដូច្នេះវាពីរបន្តភាពដែលមានទេសភាព សំរាប់ជំរុញការអភិវឌ្ឍន៍នៃគម្រោងទីផ្សាររបស់យើង។វាធ្វើឲ្យពួកគេអាចបង្កើតចំណុចប្រទាក់ថ្មីៗបន្ថែមទៀត ក្នុងប្រព័ន្ធការដំណើរការ។ ឧបករណ៍ដែលធ្វើឡើងពីស៊ុមដែកស្រទាប់នេះ ប្រើបានសម្រួល និងងាយស្រួលក្នុងការតំឡើង ការផ្លាស់ប្តូរ និងកែលម្អ។ស៊ុមដែកស្រទាប់ដែលមានរាងប្លែកត្រូវបានផលិតពីដែកដែលមានគុណភាពខ្ពស់ ដូចដែលវាធានាសុវត្ថិភាពនិងភាពរឹងមាំក្នុងការជួយសុខភាពបរិស្ថាន និងភាពប្រសើរនៃការប្រើប្រាស់។ បន្ទាប់ពីអនុវត្តន៍របៀបដែលបានរៀបរំ ដែកនេះត្រូវបានគេអនុម័តថាពួកគេអាចធ្វើបានក្នុងការបង្កើនការប្រើប្រាស់ដែកស្រទាប់។ក្នុងបច្ចុប្បន្ននេះ ស៊ុមដែកស្រទាប់ដែលមានរាងប្លែកត្រូវបានប្រើយ៉ាងពេញនិយមក្នុងគំរោងសំណង់នានា ដូចជា ផ្នែកក្រៅសំណង់ បាសាកសំណង់ និងអាគារសហគ្រាស។ ដោយសារតែគុណសម្បត្តិ និងសមត្ថភាពការប្រើប្រាស់ ក្នុងការចូលរួមជាមួយផលិតផលផ្សេងៗ ទាំងនេះបានបង្កើនអត្ថច]],[[ាននៃការប្រើប្រាស់ស៊ុមដែកស្រទាប់ដែលមានរាងប្លែក យ៉ាងខ្លាំងនៅក្នុងវិស័យសំណង់ខ្លាំង។ សូម្បីតែធនធានធំៗ នៅក្នុងការអភិវឌ្ឍន៍ផ្នែកជំនាញថ្មីៗនានា Sereated Steel Bar Grating មើលទៅដូចជារបៀបធម្មតា ប៉ុន្តែមិនត្រឹមតែតែជួយសម្រួលការងារ ប៉ុន្តែថែមទៀតវាបង្ហាញពីភាពឈានមុខនៃបច្ចេកវិទ្យាក្នុងការសាងសង់។

serrated steel bar grating

Hindi lamang tibay ang alalahanin sa konstruksyon kundi pati na rin ang kaligtasan. Ang floor grating steel ay nag-aalok ng anti-slip na katangian na hindi madaling makakalimutan. Sa mga lugar na madalas na basa o may panganib ng pagdulas, ang mga grating na ito ay nagbibigay ng mas mahusay na traksyon, na nagbabawas ng posibilidad ng pagkakabasag at aksidente sa mga manggagawa.

Cuối cùng, việc nghiên cứu và phát triển các kích thước lưới răng cưa mới cũng rất cần thiết để đáp ứng sự phát triển không ngừng của công nghệ. Các nhà nghiên cứu không ngừng thử nghiệm và tối ưu hóa kích thước và hình dạng của lưới răng cưa nhằm nâng cao hiệu suất và sự linh hoạt trong ứng dụng.

Heavy Duty Steel Grating An Essential Choice for Industrial Applications

---

3. Estetiska alternativ Med en mängd olika stilar, färger och material tillgängliga kan golvristor anpassas för att passa olika designkoncept. Detta ger möjlighet att kombinera funktion och stil i byggnadens interiör.

floor grating for sale

次に、ステンレス製チャンネルドレインの利点について考えてみましょう。まず、デザインの柔軟性が挙げられます。これらのドレインは、高い強度を持ちながらもスリムなデザインを持っており、建物や舗装されたエリアの美観を損なうことなく設置できます。また、さまざまなサイズや形状で提供されるため、特定のニーズに合わせたカスタマイズが可能です。

stainless steel channel drain

Floor Grating Qiyməti Onun Əhəmiyyəti və Seçim Kriteriyaları

Yhteenvetona voidaan todeta, että kevyet kävelytiet ja ritilät tarjoavat useita etuja, jotka tekevät niistä erinomaisen vaihtoehdon monenlaisille rakennus- ja infraprojekteille. Ne ovat kestäviä, turvallisia ja esteettisiä, mikä tekee niistä täydellisen valinnan moderniin ympäristöön.

از طرفی، نگهداری و نظافت منظم این گریتها برای حفظ عملکرد بهینه آنها ضروری است. تجمع زباله، برگ و سایر مواد بر روی سطح گریتها میتواند تأثیر منفی بر کارایی آنها داشته باشد. لذا برنامهریزی منظم برای نظافت و بازرسی دوردستی این ساختارها ضروری به نظر میرسد.

In addition to its durability, galvanized steel bar grating is also cost-effective, offering a strong and reliable solution at a competitive price point. Its flexibility in design allows for customization to fit various project requirements, making it a versatile option for different applications.

Applications of Galvanized Grating

A drenagem eficiente é fundamental para a manutenção de áreas urbanas e rurais, especialmente em regiões que recebem chuvas intensas. Entre os diversos sistemas de drenagem disponíveis no mercado, a grelha de trincheira de 4 polegadas se destaca como uma solução prática e eficaz. Neste artigo, vamos explorar a importância, as vantagens e as aplicações dessa grelha de drenagem.

Recycling: In recycling facilities, shaker screens are used to separate and classify recyclable materials, such as plastics, glass, and metals. This allows for efficient sorting and processing of recyclable waste.

In addition to their strength, grated metal floors offer outstanding safety features. The non-slip surface of many grated floor systems minimizes the risk of slips and falls, a crucial consideration in environments where workers are moving quickly or handling heavy loads. Furthermore, the open floor design aids in safely redirecting spills, allowing liquids to drain away quickly and preventing hazardous build-up. This is particularly important in industrial kitchens, chemical plants, and other facilities where spills are common.

grated metal floor

Stålristtrappor En Hållbar och Modern Lösning

Steel Grating supply

3. Tính năng nổi bật

twisted bar grating

The manufacturing process also affects the cost. Stainless steel grating is typically produced through methods such as welding or pressing. Hand-welded grating tends to be more expensive due to the labor-intensive process but often results in a superior, more precise product. On the other hand, pressed grating can be more cost-effective but may not offer the same level of quality or customization.

stainless steel grating price

High-Frequency Screens: High-frequency screens operate at higher vibration frequencies, allowing for the separation of fine particles and improved dewatering. They are commonly used in mining and industrial applications.

5. Versatility Open floor grating is incredibly versatile and can be used in various applications. It is commonly found in platforms, stairways, and catwalks, as well as in manufacturing plants, chemical facilities, and water treatment plants.

Understanding Grating Hot Dip Galvanized Steel Benefits and Applications

Additionally, floor grating panels contribute to enhanced ventilation. In areas where air circulation is critical, such as chemical processing plants and power generation facilities, these panels allow for optimal airflow. By preventing the buildup of heat and harmful vapors, they help to create a safer working environment while improving overall efficiency. Moreover, the open design of grating panels can also aid in the dispersal of light, making dark areas more illuminated and safe for employees.

floor grating panels

Resistenza alla Corrosione

En termes de durabilité, les matériaux utilisés pour fabriquer le filet sont conçus pour résister aux intempéries et aux environnements difficiles. Les câbles en acier, ainsi que le traitement anti-corrosif appliqué, garantissent que le « rope helideck mesh » maintienne son intégrité structurelle même après des années d'utilisation. Cela réduit non seulement les coûts d'entretien, mais assure également une longévité accrue de l'équipement, un aspect non négligeable dans les industries où chaque investissement doit être justifié par un retour sur investissement optimal.

Choosing the right shale shaker screen mesh and maintaining it properly are essential for ensuring optimal.

Material Types and Their Costs