high quality warman rubber lined slurry pump manufacturer

Latest articles

>Dredge pumps are a special category of pumps used in the dredging process. Dredging is the process of transporting submerged sediments (usually sand, gravel or rock) from one area to another. Dredging takes place in the shallow waters of lakes, rivers or seas for land reclamation, dredging, flood control, new harbours or expansion of existing harbours. The various industries that use dredge pumps are therefore the construction industry, mining, the coal industry and the oil and gas industry.

high quality warman rubber lined slurry pump manufacturer...

high quality warman rubber lined slurry pump manufacturer 【high quality warman rubber lined slurry pump manufacturer】

Read MoreFor pumping abrasive slurries, these types of pumps can also be made from specialised high-wear alloys. Hardened stainless steel is also a common choice for abrasive slurries.

high quality warman rubber lined slurry pump manufacturer...

high quality warman rubber lined slurry pump manufacturer 【high quality warman rubber lined slurry pump manufacturer】

Read MoreAier is pumping experts and offer some useful tips to maintain your >slurry pump.

high quality warman rubber lined slurry pump manufacturer...

high quality warman rubber lined slurry pump manufacturer 【high quality warman rubber lined slurry pump manufacturer】

Read MoreTraditionally, centrifugal pumps are used to pump highly abrasive slurries. Centrifugal pumps use the force generated by the rotating impeller to impinge kinetic energy into the slurry.

high quality warman rubber lined slurry pump manufacturer...

high quality warman rubber lined slurry pump manufacturer 【high quality warman rubber lined slurry pump manufacturer】

Read Moretesting station in the world, and its test capacity can reach 13000m³/h. Annual output of our products is 10000

high quality warman rubber lined slurry pump manufacturer...

high quality warman rubber lined slurry pump manufacturer 【high quality warman rubber lined slurry pump manufacturer】

Read MoreA dredge pump contains a pump casing and an impeller. The impeller is mounted in the pump casing and connected to the drive motor via a gearbox and shaft. The front part of the pump casing is sealed with a suction cover and connected directly to the suction pipe of the dredger. The discharge port of the dredge pump is located near the top of the dredge pump and is connected to a separate discharge line.

high quality warman rubber lined slurry pump manufacturer...

high quality warman rubber lined slurry pump manufacturer 【high quality warman rubber lined slurry pump manufacturer】

Read MoreCorrosiveness of the liquid or slurry mixture: More corrosive slurries will wear pump components faster and may dictate the choice of pump manufacturing materials.

high quality warman rubber lined slurry pump manufacturer...

high quality warman rubber lined slurry pump manufacturer 【high quality warman rubber lined slurry pump manufacturer】

Read MoreSlurry pump design

high quality warman rubber lined slurry pump manufacturer...

high quality warman rubber lined slurry pump manufacturer 【high quality warman rubber lined slurry pump manufacturer】

Read MoreIf you want to know more information about the best slurry pumps wholesale, welcome to >contact us today or request a quote.

high quality warman rubber lined slurry pump manufacturer...

high quality warman rubber lined slurry pump manufacturer 【high quality warman rubber lined slurry pump manufacturer】

Read MoreIf you want to get more information about the slurry pumps for sale, welcome to target=_blank title=Contact Us>contact us.

high quality warman rubber lined slurry pump manufacturer...

high quality warman rubber lined slurry pump manufacturer 【high quality warman rubber lined slurry pump manufacturer】

Read More

Popular articles

- sets or tons on high chrome alloy castings. Main products are Type WA, WG, WL, WN, WY, WZ, etc. Size: 25-1200mm,

- The slurry must be pumped from the absorber tank to the top of the spray tower where it is sprayed downwards as a fine mist to react with the upward moving flue gas. With pumping volumes typically in the range of 16,000 to 20,000 gallons of slurry per minute and heads of 65 to 110 feet, rubber lined slurry pumps are the optimal pumping solution.

- Using rubber as a wear lining material means

- Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

- How Slurry Pumps Differ From Standard Pumps?

- Customised solutions

Latest articles

-

A quench plan, as the name indicates, is designed to quench or cool the seal. It is normally used if short periods of dry running are expected. As illustrated bellow, the fluid is introduced into the area between the back of the seal faces and the close fit exit on the drive side of the pump.

-

Submersible Slurry Pump

-

Sites often rely on centrifugal pumps to provide slurry service. These pumps (and their associated piping systems) require special provisions that demand detailed knowledge of the properties of solids and slurries to prevent wear, corrosion, erosion and other adverse effects such as solids settling. Specifying the optimum combination of speed, geometry and material requires a proper balance of often conflicting pump priorities; this requires consideration of stable operation, maximum wear life, operational flexibility and minimum energy consumption.

-

Choosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

-

How does a dredge pump work?

-

Horizontal centrifugal pumps are commonly used for slurry service, but vertical and other types of pumps are better suited to certain specific applications. Centrifugal pumps for handling slurries have features tailored to specific services that reflect the corrosive or abrasive nature of the slurry and the concentration of solids. These may include the choice of materials, the use of liners or even different drive sizes.

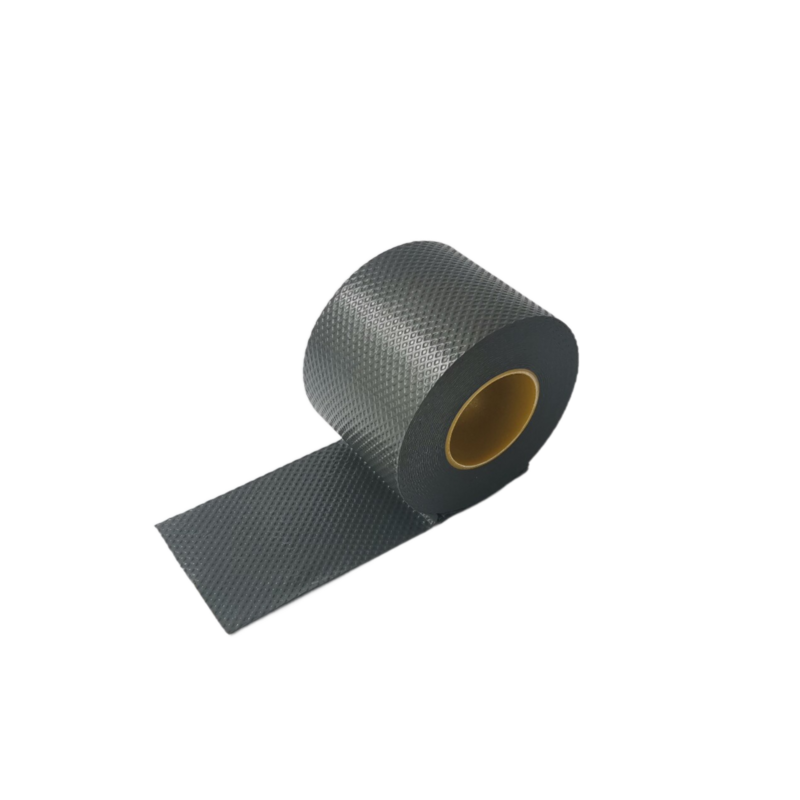

As we continue to seek effective and long-lasting solutions for everyday challenges, products like 3M Vulcanizing Tape remind us of the importance of quality in simplicity. When the need arises, this tape stands ready to provide a convenient, durable, and effective repair solution, reinforcing the idea that sometimes, the simplest tools can be the most powerful.

Protection It provides protection against abrasion, moisture, and corrosion, ensuring the longevity and reliability of wires and cables Protection It provides protection against abrasion, moisture, and corrosion, ensuring the longevity and reliability of wires and cables

Protection It provides protection against abrasion, moisture, and corrosion, ensuring the longevity and reliability of wires and cables Protection It provides protection against abrasion, moisture, and corrosion, ensuring the longevity and reliability of wires and cables automotive wire wrap tape.

automotive wire wrap tape.Black Silicone Self-Fusing Sealing and Insulating Tape.

Electrical tapes are typically made with a polyvinylchloride (PVC) backing and a non-corrosive rubber-based adhesive. The backing is what gives it the ability to stretch and conform to cables and wiring. This stretch is a critical characteristic of electrical tapes because it allows the tape to wrap tightly around cables for long-lasting insulation. Most cloth, film, and other types of tapes do not possess the elongation characteristics that allow electrical tapes to function properly.

fire resistant adhesive tape. Its ability to resist flames and heat helps to protect sensitive components and prevent fires, enhancing vehicle safety.

fire resistant adhesive tape. Its ability to resist flames and heat helps to protect sensitive components and prevent fires, enhancing vehicle safety.PlB self-amalgamating Tape

It can be easily stretched and molded to fit uneven surfaces, making it an ideal solution for sealing complex shapes and contours It can be easily stretched and molded to fit uneven surfaces, making it an ideal solution for sealing complex shapes and contours

It can be easily stretched and molded to fit uneven surfaces, making it an ideal solution for sealing complex shapes and contours It can be easily stretched and molded to fit uneven surfaces, making it an ideal solution for sealing complex shapes and contours butyl rubber tape. This makes it particularly useful in automotive and marine applications, where a tight seal is essential for preventing leaks and protecting sensitive components.

butyl rubber tape. This makes it particularly useful in automotive and marine applications, where a tight seal is essential for preventing leaks and protecting sensitive components. It is particularly useful in construction sites, where wires might be exposed to rough handling or harsh conditions It is particularly useful in construction sites, where wires might be exposed to rough handling or harsh conditions

It is particularly useful in construction sites, where wires might be exposed to rough handling or harsh conditions It is particularly useful in construction sites, where wires might be exposed to rough handling or harsh conditions insulation pvc tape.

insulation pvc tape.When you own a home with a well, problems can arise unexpectedly.

4. Wide Temperature Range

Floor marking tape is an essential tool for creating clear boundaries and organizing workspaces in a variety of environments, including warehouses, factories, hospitals, and schools. Its bright colors and highly visible design make it easy to mark off areas for safety, organization, and traffic flow.

As the global demand for electrical products continues to rise, the significance of PVC electrical insulation tape is increasingly recognized. Its versatility, coupled with its affordability and durability, makes it an essential item in the wholesale market. Suppliers offering quality PVC insulation tape are poised to meet the diverse needs of various industries, ensuring safety and reliability in electrical applications. Whether for industrial use or DIY projects, PVC electrical insulation tape remains a cornerstone of effective electrical management and insulation solutions.