2 inch slurry pump manufacturers

Latest articles

The Company Adopts Advanced Computer Aided Engineering Software

2 inch slurry pump manufacturers...

2 inch slurry pump manufacturers 【2 inch slurry pump manufacturers】

Read More- Reduced space requirements - Since submersible slurry pumps operate directly in the slurry, they do not require any additional support structures.

2 inch slurry pump manufacturers...

2 inch slurry pump manufacturers 【2 inch slurry pump manufacturers】

Read MoreChoosing the right material for a slurry pump is another key process in determining the right pump for handling slurry. If the slurry is highly abrasive with neutral pH, then the best material of construction is Hi-Chrome. this metallurgy has the highest Brinell hardness and can withstand the abrasiveness of the slurry.

2 inch slurry pump manufacturers...

2 inch slurry pump manufacturers 【2 inch slurry pump manufacturers】

Read MoreThe concept of the >slurry pump and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

2 inch slurry pump manufacturers...

2 inch slurry pump manufacturers 【2 inch slurry pump manufacturers】

Read MoreWe know that the right rubber and ceramic liners work very well. They also last longer and can withstand more demanding use. They can also be replaced, thereby extending the life of the pump while reducing operating costs. You can also customise your pump with a variety of ceramic parts, including bushings, pump housings, impellers, wet ends and even seals.

2 inch slurry pump manufacturers...

2 inch slurry pump manufacturers 【2 inch slurry pump manufacturers】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

2 inch slurry pump manufacturers...

2 inch slurry pump manufacturers 【2 inch slurry pump manufacturers】

Read MoreWhen dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

2 inch slurry pump manufacturers...

2 inch slurry pump manufacturers 【2 inch slurry pump manufacturers】

Read MoreThe Difference Between Flushing And Quenching in Slurry Pump Seals

2 inch slurry pump manufacturers...

2 inch slurry pump manufacturers 【2 inch slurry pump manufacturers】

Read MoreFewer and thicker vanes on the impeller. This makes it easier for solids to pass through than the 5-9 vanes on a standard centrifugal pump - typically 2-5 vanes.

2 inch slurry pump manufacturers...

2 inch slurry pump manufacturers 【2 inch slurry pump manufacturers】

Read MoreSettling slurries are formed by coarse particles, which tend to form unstable mixtures. Special attention should be paid to flow and power calculations when selecting a pump. Most slurry applications consist of coarse particles and therefore have a higher abrasion resistance.

2 inch slurry pump manufacturers...

2 inch slurry pump manufacturers 【2 inch slurry pump manufacturers】

Read More

Popular articles

- Quenching is defined as the introduction of a neutral fluid (usually water or steam) into the atmospheric side of the seal to prevent the formation of solids that may interfere with movement or be used for other purposes.

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- Despite the complexity of internal flow patterns, the overall performance of dredge pumps is predictable.

- The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

- Slurry pump vs mud pump

- Determine the operating parameters of the pump.

Latest articles

-

What is the pump constructed of?

-

Compared to standard centrifugal pumps, centrifugal pumps optimized for slurry pumping typically have the following features.

-

Slurry pump design

-

Depending on your own requirements, propeller seals, mechanical seals or packing seals can be used.

-

If you have experience pumping slurry, you know it is not an easy task. Slurries are heavy and difficult to pump. They can cause excessive wear on the pump and its components, and if they don't move fast enough, they can clog the suction and discharge lines. Most importantly, it can be a challenge to keep a slurry pump in use for a reasonable period of time. However, there are steps you can take to extend the life of your slurry pump and reduce the challenges of pumping slurry.

-

Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

Links

Efficiency and Productivity

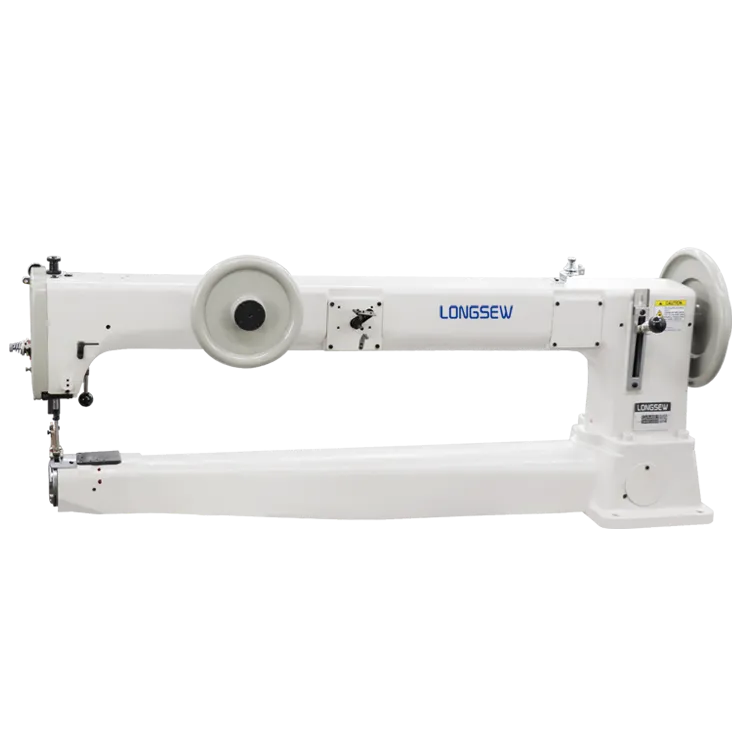

Heavy Duty Sewing Machine Motors The Backbone of Industrial Sewing

- Quilting The precision and consistency of the lock stitch make it the preferred choice for quilters, ensuring that intricate designs remain intact through wash and wear.

The Artisan's Touch

In conclusion, the FIBC sewing machine head plays a pivotal role in the manufacturing process of Flexible Intermediate Bulk Containers. Its advanced engineering and technology contribute to producing high-quality, robust, and reliable bags that meet the varied needs of industries worldwide. As the demand for efficient and sustainable packaging solutions continues to grow, investing in high-performance sewing machine heads will be essential for manufacturers looking to stay ahead in the competitive market. By embracing innovation and prioritizing quality, the future of FIBC production looks promising, paving the way for more efficient and sustainable industrial practices.

- In addition to their efficiency and versatility, saddle stitch machines also produce a professional-looking finished product

What is a Programmable Pattern Sewing Machine?