wholesale slurry pump closed impeller

Latest articles

Compared to standard centrifugal pumps, centrifugal pumps optimised for slurry pumping usually have the following features.

wholesale slurry pump closed impeller...

wholesale slurry pump closed impeller 【wholesale slurry pump closed impeller】

Read MoreSlurry pump impeller, is one of the most important parts of centrifugal slurry pumps. Depending on the application, slurry pump impeller selection is crucial to slurry pump performance. Slurry applications can be especially hard on the impeller of slurry pumps because of their abrasive nature. In order slurry pumps operates efficiently and stand up to the test of time, impeller has to be selected properly for slurry pumps.

wholesale slurry pump closed impeller...

wholesale slurry pump closed impeller 【wholesale slurry pump closed impeller】

Read More-When pumping abrasive slurries, it is essential to use wear-resistant components with a high chromium content. But more is not always better - above 25%, the impeller becomes brittle.

wholesale slurry pump closed impeller...

wholesale slurry pump closed impeller 【wholesale slurry pump closed impeller】

Read MoreWe use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

wholesale slurry pump closed impeller...

wholesale slurry pump closed impeller 【wholesale slurry pump closed impeller】

Read MoreThe concept of the , slurry pump, and mud pump is very close, many people are not quite clear. Although slurry pumps and mud pumps are impurities pump, if you fully understand the two pumps, you can differentiate them very clearly from the application and transmission medium characteristics. What is the difference between the slurry pump and mud pump? Four aspects to distinguish the slurry and mud pumps.

wholesale slurry pump closed impeller...

wholesale slurry pump closed impeller 【wholesale slurry pump closed impeller】

Read MoreHow much solids damage can the customer tolerate?

wholesale slurry pump closed impeller...

wholesale slurry pump closed impeller 【wholesale slurry pump closed impeller】

Read MoreRepairable - target=_blank title=Rubber Lined Slurry Pumps>Rubber lined slurry pumps can be repaired by simply replacing the bushing.

wholesale slurry pump closed impeller...

wholesale slurry pump closed impeller 【wholesale slurry pump closed impeller】

Read MoreWorking principle

wholesale slurry pump closed impeller...

wholesale slurry pump closed impeller 【wholesale slurry pump closed impeller】

Read MoreAIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

wholesale slurry pump closed impeller...

wholesale slurry pump closed impeller 【wholesale slurry pump closed impeller】

Read MoreThe Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

wholesale slurry pump closed impeller...

wholesale slurry pump closed impeller 【wholesale slurry pump closed impeller】

Read More

Popular articles

- The basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

- Slurry pump considerations

- Damage to slurry pumps can range from burst seals to bearings and component housings wearing out where they join, to impellers corroding due to cavitation or severe wear and so on. However, there are solutions to these problems.

- Pumping mud is not as easy as pumping water. Depending on the type of slurry, there are many variables in choosing the right pump for the slurry. There is no formula or set-in-stone answer as to what the best slurry pump design is. You must combine knowledge and application details to select the ideal target=_blank title=Slurry Pump>slurry pump. Let's talk about how slurry pumps differ from standard pumps and how to narrow your choices.

- Fine-grained sand can be extremely abrasive and typically wears slurry pumps quickly. Characteristics of coarse aggregates that can affect pump performance are size, shape and surface texture, as well as gradual changes in particle size, while fine materials can create excessive friction in the pipe.

- Dredge pumps are designed to transfer large quantities of fluids and solids.

Latest articles

-

Low slurry flow rates

-

Find a professional slurry pump supplier

-

The frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

-

Adapting a pump to its precise application - be it pulp and paper, gas and oil, mining or industrial applications - will have a direct impact on its service life. That's why our bespoke pumps have the unique advantage of interchangeable components. These components include slurry valves, which can be replaced every 6 months as a preventive measure and every 12 months for regular maintenance, depending on the application.

-

The frame plate for WAJ series pumps has interchangeable hard metal or pressure moulded elastomer liners. The impellers are made of pressure moulded elastomer liners.The shaft seals for WAJ series can be packing seal, centrifugal seal or mechanical seal.

-

Why would maintenance personnel want to adjust a high-speed rotating impeller to a static lining component while the unit is running? Even if interlocking devices are used to prevent static and non-static components from coming into contact, how credible are these features and what are the implications for pump wear parts, bearings and motors if these two components come into contact?

Links

When it comes to the specifics of sewing leather, handheld machines are well-equipped to tackle various projects. Many models come with specialized needles and heavy-duty threads designed to pierce through tough materials. Users can create everything from wallets and bags to belts and jackets. The ability to handle multiple layers of leather makes these machines particularly effective for seam work, ensuring that even complex designs are executed with precision and care.

handheld leather sewing machine

1. Durability and Strength The primary advantage of a single stitch machine is that it provides strong, long-lasting seams. This is essential when working with leather, as the weight and toughness of the material require stitching methods that can withstand the material's natural properties.

twin stitch needle. The double stitching created by these needles is stronger and more secure than a single row of stitching, making it ideal for items that will see a lot of use. This is especially important for items like bags, wallets, and clothing, where seams are subjected to a lot of stress. By using twin stitch needles, you can ensure that your finished products will hold up well over time.

In the ever-evolving world of sewing, the long arm zig zag sewing machine stands out as a revolutionary tool for both hobbyists and professional seamstresses alike. This versatile machine combines the features of long arm sewing with the capabilities of zig zag stitching, making it an essential ally for those who take their sewing projects seriously.

Understanding Chain Stitch

The Importance of Industrial Overlock Sewing Machines in Modern Textiles

You might want to consider the size and weight of the machine. When you purchase a regular sewing machine . This makes it perfect to take on vacation with you. However, a heavy-duty machine will be heavier and bulkier. While you can still lift and re-position the device, carrying it for long distances might be more difficult.

Another key benefit of heavy-duty denim thread is its ease of use. Its thickness and strength make it less prone to breaking during the sewing process. For those using sewing machines, this type of thread glides smoothly through the machine, facilitating a more enjoyable sewing experience. Additionally, because heavy-duty denim thread is compatible with various sewing machines, hobbyists and professionals alike can use it without having to invest in specialized equipment.

Key Applications of Flat Bed Sewing Machines

The versatility of an overlocker extends beyond seam finishing. Many models come equipped with the capability to create various stitch types, including rolled hems and flatlock stitches. A rolled hem is perfect for delicate fabrics such as chiffon and silk, adding a refined edge without bulk. On the other hand, flatlock stitches are excellent for joining fabrics, especially in activewear, as they provide a comfortable, minimal-seam finish.

what is an overlocker for

To fully leverage the capabilities of a double needle lockstitch machine, proper maintenance is essential. Regularly checking and replacing needles, maintaining the tension of the threads, and keeping the machine clean from lint and debris will help ensure consistent performance. Additionally, operators should be trained to adjust stitch density and tension settings according to the specific fabric being used, which can further enhance sewing quality.

3. Insert the Double Needle

1. Choose the Right Needle Size Long upholstery needles come in various sizes, and selecting the appropriate size for your project is crucial. Thicker fabrics and multiple layers may require a larger needle size to facilitate a smooth sewing experience.

As the leatherworking industry continues to evolve, the cylinder arm sewing machine remains an invaluable asset for artisans and manufacturers alike. With their innovative design and robust features, these machines not only enhance productivity but also ensure precision in every stitch. Whether creating high-fashion items or durable goods, the cylinder arm sewing machine provides the tools necessary for success, making it a quintessential element in the toolkit of leatherworkers today. Embracing this technology not only enhances craftsmanship but also allows artisans to push the boundaries of creativity in leather design, ensuring a bright future for the craft.

Types of Heavy-Duty Thread

Conclusion

In anticipation of future trends, the stitching techniques associated with the zigzag foot continue to evolve, including computerized sewing machines that allow for intricate designs and patterns with minimal effort. As the sewing community embraces innovation, the zigzag foot remains a crucial component of sewing versatility.

- Walking Foot Mechanism A walking foot is essential for sewing multiple layers of leather, as it helps maintain even tension across the fabric. This feature can prevent puckering and ensure a smooth finish.

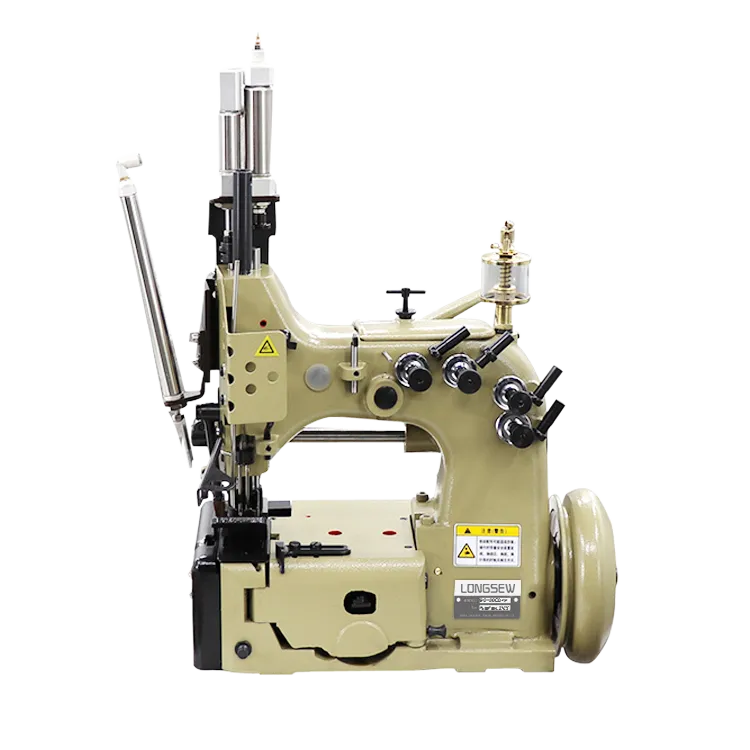

Overall, woven sack sewing machines play a crucial role in the production of woven sacks, providing a fast, efficient, and reliable way to stitch together the durable polypropylene material. These machines are essential for industries that rely on woven sacks for packaging and transportation, ensuring that goods are safely stored and transported in a secure and durable packaging solution.