high quality wetted parts for slurry pump supplier

Latest articles

Slurry Pump

high quality wetted parts for slurry pump supplier...

high quality wetted parts for slurry pump supplier 【high quality wetted parts for slurry pump supplier】

Read MoreThese conditions include

high quality wetted parts for slurry pump supplier...

high quality wetted parts for slurry pump supplier 【high quality wetted parts for slurry pump supplier】

Read MoreWhat is the pump constructed of?

high quality wetted parts for slurry pump supplier...

high quality wetted parts for slurry pump supplier 【high quality wetted parts for slurry pump supplier】

Read MoreSlurry Pump

high quality wetted parts for slurry pump supplier...

high quality wetted parts for slurry pump supplier 【high quality wetted parts for slurry pump supplier】

Read MoreSelecting the right pump for slurries is critical to get the most bang for your buck. Basic pump components, such as the impeller size and design, material of construction, and discharge configurations must be considered to ensure the pump will hold up against the wear caused by an abrasive slurry. Slurry pumps are generally larger in size when compared to low-viscosity liquid pumps and usually require more horsepower to operate because they're less efficient. Bearings and shafts must be more rugged and rigid as well.

high quality wetted parts for slurry pump supplier...

high quality wetted parts for slurry pump supplier 【high quality wetted parts for slurry pump supplier】

Read MoreWY type pump casing is made of abrasion resistant metal, impeller material can be abrasion resistant metal or rubber. The submerged parts of WYJ are all lined with rubber, for transfer corrosive slurry.

high quality wetted parts for slurry pump supplier...

high quality wetted parts for slurry pump supplier 【high quality wetted parts for slurry pump supplier】

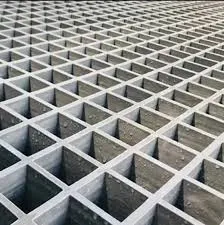

Read MoreFloor drainage

high quality wetted parts for slurry pump supplier...

high quality wetted parts for slurry pump supplier 【high quality wetted parts for slurry pump supplier】

Read MoreHow Slurry Pumps Differ From Standard Pumps?

high quality wetted parts for slurry pump supplier...

high quality wetted parts for slurry pump supplier 【high quality wetted parts for slurry pump supplier】

Read MoreSlurry Pump Speed

high quality wetted parts for slurry pump supplier...

high quality wetted parts for slurry pump supplier 【high quality wetted parts for slurry pump supplier】

Read MoreOne of the most frequently asked questions from our team of pump experts is: How do I pump slurry? With this in mind, our team of experts have provided a useful guide to pumping slurry.

high quality wetted parts for slurry pump supplier...

high quality wetted parts for slurry pump supplier 【high quality wetted parts for slurry pump supplier】

Read More

Popular articles

- Slurry pumps with rubber lining are the ideal pump for the mineral sand industry. They have a special rubber lining that makes them heavy duty pumps capable of withstanding high levels of abrasion.

- As new coal-fired power plants come on line to meet the growing demand for electricity in the US and around the world, there is an increasing need to clean plant emissions to meet clean air regulations. Special pumps help to operate these scrubbers efficiently and handle the abrasive slurries used in the flue gas desulphurisation (FGD) process.

- Under ideal conditions, a dredge pump can produce fluid acceleration greater than the speed of its fastest moving component.

- Slurry pump construction materials

- Vertical Slurry Pumps Pump Sewage More Efficiently

- The solution is to choose a >heavy duty slurry pump and, just as importantly, to use a custom built unit with replaceable parts. At Aier Machinery, building your custom slurry pump is one of our areas of expertise. We design your slurry pump to your specifications and application.

Latest articles

-

>Slurry Pump

-

The Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

-

Auxiliary equipment

-

Lifetime use

-

There are three different >types of slurry pump impellers; open, closed, and semi-open. Each has its own strengths and weaknesses, depending on the application. Some are better for solids handling, others are better for high efficiency.

-

Submersible Slurry Pump

Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas

Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas Modern techniques such as horizontal drilling and hydraulic fracturing have significantly increased access to otherwise inaccessible reserves of oil and gas In this situation, you should stand pat and not take any additional cards In this situation, you should stand pat and not take any additional cards

In this situation, you should stand pat and not take any additional cards In this situation, you should stand pat and not take any additional cards The ability to use a single tool for multiple applications saves time and reduces the need for inventory management The ability to use a single tool for multiple applications saves time and reduces the need for inventory management

The ability to use a single tool for multiple applications saves time and reduces the need for inventory management The ability to use a single tool for multiple applications saves time and reduces the need for inventory management