high quality dredge pump parts suppliers

Latest articles

The Difference Between Flushing And Quenching in Slurry Pump Seals

high quality dredge pump parts suppliers...

high quality dredge pump parts suppliers 【high quality dredge pump parts suppliers】

Read Morefactors-to-consider-when-choosing-a-slurry-pump

high quality dredge pump parts suppliers...

high quality dredge pump parts suppliers 【high quality dredge pump parts suppliers】

Read MoreSlurry Pump

high quality dredge pump parts suppliers...

high quality dredge pump parts suppliers 【high quality dredge pump parts suppliers】

Read MoreThe Company Adopts Advanced Computer Aided Engineering Software

high quality dredge pump parts suppliers...

high quality dredge pump parts suppliers 【high quality dredge pump parts suppliers】

Read MoreCapacity: 5-30000m3/h, Head: 5-120m. The company can produce different materials including High Chromium White Iron, Super High Chromium Hypereutectic White Iron, Low Carbon High Chromium Alloy, Carbon Steel, Stainless Steel, Duplex Stainless Steel, Ductile Iron, Grey Iron, etc. We can also provide natural rubber, elastomer rubber parts and pumps.

high quality dredge pump parts suppliers...

high quality dredge pump parts suppliers 【high quality dredge pump parts suppliers】

Read MoreThere is a science behind the design of a >slurry pump, based primarily on the processes and tasks it will perform. This is why it is important to use the right slurry pump for your specific needs. In a field that encompasses so many specialities, long-lasting, efficient and reliable quality equipment is essential.

high quality dredge pump parts suppliers...

high quality dredge pump parts suppliers 【high quality dredge pump parts suppliers】

Read MoreChoosing the right target=_blank title=Slurry Pump>slurry pump for your application can be a daunting task. Slurry pumps can be found in almost all industries and play a vital role in many processes.The 4 key aspects to look for when determining the right slurry pump are slurry pump design, pump materials of construction, slurry pump seals, and proper slurry pump power sizing.Next, the target=_blank title=Slurry Pump Supplier>slurry pump supplier will share them with you.

high quality dredge pump parts suppliers...

high quality dredge pump parts suppliers 【high quality dredge pump parts suppliers】

Read MoreSubmersible pumps offer many advantages over dry installation or even semi-submersible sump pumps. Submersible pumps are more flexible and efficient than alternatives.

high quality dredge pump parts suppliers...

high quality dredge pump parts suppliers 【high quality dredge pump parts suppliers】

Read MoreOne problem with centrifugal pumps is that the velocity and shear forces within the pump may damage the slurry/solids. Typically, twin-screw pumps cause the least damage to solids in the slurry.

high quality dredge pump parts suppliers...

high quality dredge pump parts suppliers 【high quality dredge pump parts suppliers】

Read MoreCaution: A common mistake is to over-pressurise the box and damage the expensive mechanical seal.

high quality dredge pump parts suppliers...

high quality dredge pump parts suppliers 【high quality dredge pump parts suppliers】

Read More

Popular articles

- It is often used if a short period of dry running is expected. Fluid is introduced into the area between the back of the seal face and the tight-fitting outlet on the drive side of the slurry pump.

- Slurry pump vs mud pump

- Improved flow control

- 3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

- Slurry Pump

- Rubber Lined Slurry Pump

Latest articles

-

Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

-

Slurry pump design

-

- Easy installation - Submersible pumps are relatively easy to install since the motor and worm gear are a single unit.

-

It is important that the pump you choose has components that will not wear out from abrasive slurries.

-

Low slurry flow rates

-

When dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

Links

The process of continually heating and reworking cast iron is how wrought iron is produced. The labor-intensive production procedure that results in wrought iron's characteristic laminar structure also contributes to the material's high cost. Cast iron cannot compare to this material's incredible tensile strength and flexibility.

- Another advantage of these roller systems is their compatibility with sensors and alarms. By integrating motion detectors or break-in sensors with the screen door, any unauthorized attempts to breach the door can trigger an alarm, alerting the homeowners and potentially scaring off intruders. This integration brings screen doors into the realm of proactive security measures, making them an active part of a layered security approach.

One of the key advantages of decorative cast iron elements is their durability. Unlike other materials, cast iron is resistant to rust and corrosion, making it ideal for outdoor use. This durability also ensures that cast iron elements will retain their beauty for years to come, adding value to any property or piece of furniture.

- In the realm of home and garden design, few elements exude the timeless elegance of cast iron fence panels. These sturdy and versatile structures have been gracing gardens and courtyards for centuries, offering a touch of historical charm to any outdoor space.

- Remember, prevention is better than cure. Regular cleaning of the tracks and lubrication of the wheels can significantly prolong their lifespan. A little bit of maintenance can save you from the hassle of frequent replacements.

- When it comes to aesthetics, the sliding door wheel is a stylish addition to any home or business. Available in a range of finishes and styles to match your decor, these wheels add a touch of sophistication and elegance to any room. Whether you're looking to create a modern, minimalist look or a more traditional, classic aesthetic, the sliding door wheel can help you achieve your desired ambiance.

stainless steel pull handles. Whether you’re opening a heavy door or pulling out a fully-loaded drawer, you can rely on stainless steel handles to provide a strong and sturdy grip.

It can be used in a wide range of settings, from residential homes to commercial businesses, and from personal use to institutional settings such as banks and government agencies It can be used in a wide range of settings, from residential homes to commercial businesses, and from personal use to institutional settings such as banks and government agencies

It can be used in a wide range of settings, from residential homes to commercial businesses, and from personal use to institutional settings such as banks and government agencies It can be used in a wide range of settings, from residential homes to commercial businesses, and from personal use to institutional settings such as banks and government agencies metal box with padlock. Its compact size and rugged construction make it ideal for storing items that need to be kept secure but also easily accessible.

metal box with padlock. Its compact size and rugged construction make it ideal for storing items that need to be kept secure but also easily accessible.Sturdy

Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room

Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room Designers can create thinner profiles for the windows, enhancing the view and the amount of natural light that enters a room aluminum sliding window wheels. In addition, aluminum's inherent strength enables larger window sizes, further optimizing the indoor-outdoor connection.

aluminum sliding window wheels. In addition, aluminum's inherent strength enables larger window sizes, further optimizing the indoor-outdoor connection.It involves a chemical electrolytic process, which brightens the aluminum surface without leaving any debris or deposits on it. The brightness extent is influenced by type of aluminum alloy and original surface finish of aluminum profile being processed.

Step-by-Step Repair Process

So, when it comes to wrought iron vs. aluminum fences and steel fences, which option is right for you?

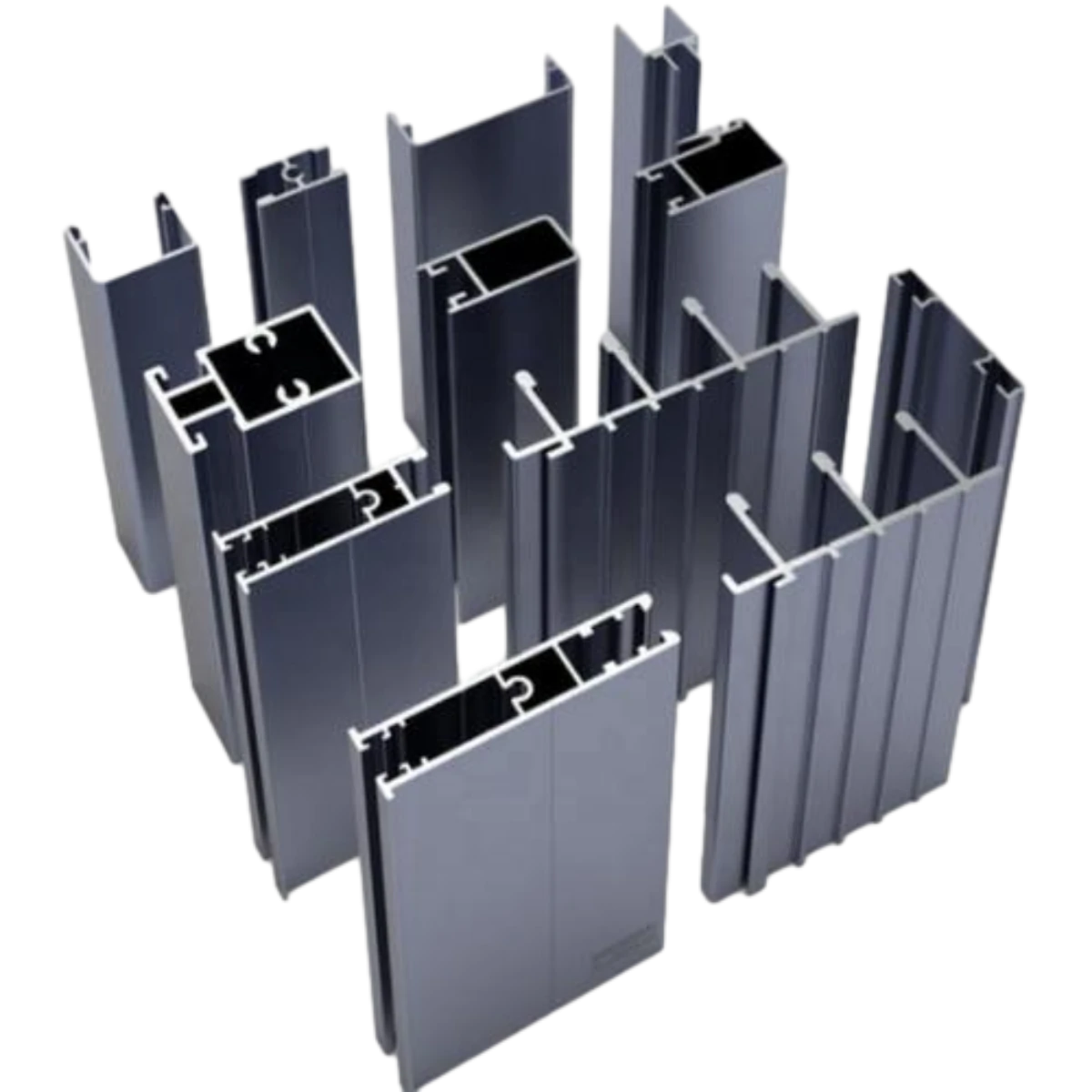

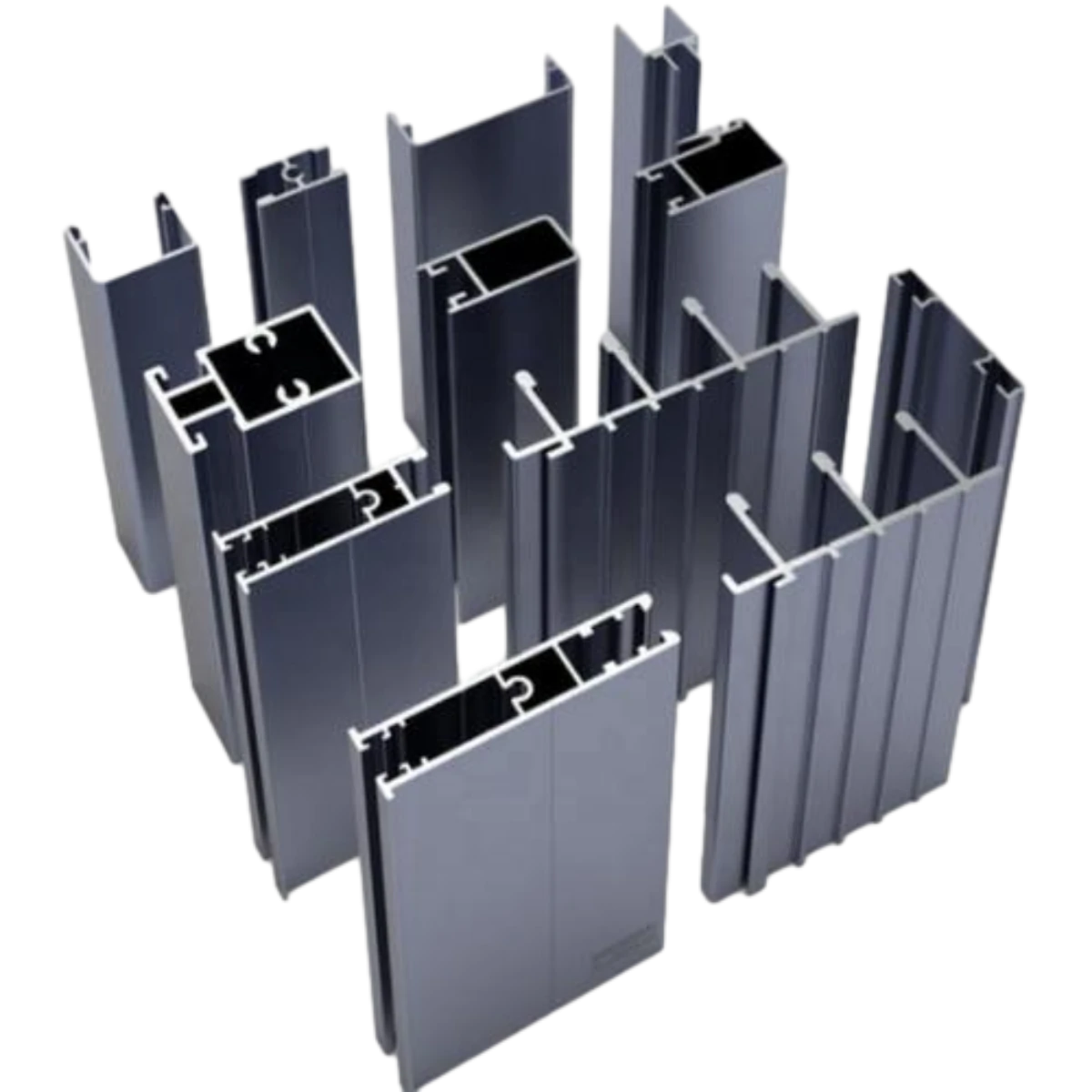

Louver aluminum alloy profile

Wrought iron gates are known for their durability and beauty. They are made from iron that is heated and shaped by hand, resulting in a strong and intricate design. These gates can be customized to fit any space, whether you are looking for a simple and classic design or something more elaborate and ornate.

5. Post Caps

One of the main benefits of cast iron fence panels is their durability. Made from a combination of iron, carbon, and silicon, cast iron is incredibly strong and resistant to corrosion. This means that these panels can withstand the elements without rusting or deteriorating, making them a long-lasting and low-maintenance option for fencing.

The process of manufacturing aluminium window profiles involves several steps, from raw material selection to final product testing. Here is an overview of the typical process:

Finally, in order to build a shed with an aluminium frame profile you need to ensure that you get a good set of plans. These will give you everything that you need so that you can build the shed with minimal hassle. Remember, even the smallest shed can look impressive if you choose the right plan. However, you should always ensure that it is the correct plan that you have purchased. This will make sure that you do not waste any materials and so that you can concentrate on the building process.